Press release -

OPW Introduces New Cost-Effective OPWlite Composite Manhole Covers and Tank Sumps

OPW, a Dover company and a global leader in fluid-handling solutions, is proud to introduce their all-new OPWlite GRP composite manhole covers and tank sumps, engineered to provide a cost-effective solution for typical petrol stations. The new OPWlite range is non-corrosive, maintenance-free and lightweight and all covers can be safely and quickly removed using OPW’s ergonomic lifting handle.

“To date, the only barrier to installing GRP composite manhole covers and tank sumps has been the larger initial outlay when compared to traditional products, but with the new OPWlite range, even the tightest budget can stretch to durable composite products.” said Joanne Westwood, OPW Business Development Director

The initial rollout of the OPWlite range is comprised of the following two product lines:

OPWlite GRP Composite Manhole Covers

Lightweight, durable and watertight, OPWlite GRP composite manhole covers are available in square (760mm or 900mm) and round (900mm or 1020mm) with an optional central dip port. All covers are load rated EN 124 C250 (load tested to EN124, class C250 permanent set and load bearing capacity test).

Specifically designed for safe lifting, the lightweight covers incorporate a lifting point for an ergonomic handle, allowing them to be removed easily and safely without the risk of operatives suffering back injury and crushed fingers or toes.

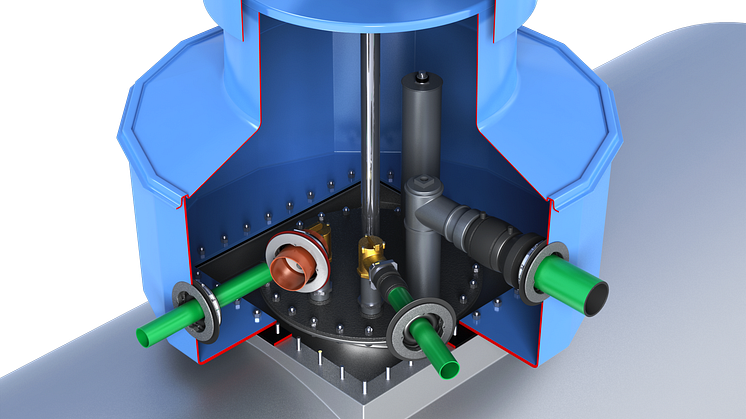

OPWlite GRP Composite Tank Sumps

Liquid-tight, stackable and vacuum testable, OPWlite tank sumps are available for internal diameters of 848mm or 1000mm with an optional central port hole. Vacuum testable during and after installation, sumps have a guaranteed uniform wall thickness which will not deform under water pressure.

Compatible with new and existing tanks as part of suction or pressure systems (including biofuels), sumps are supplied in two pieces, designed to create the maximum possible space for maintenance teams and installers to work. A uniform moulded exterior allows for easy installation of bulkhead fittings. In addition, OPWlite sumps are height adjustable, allowing for accommodation of sloping forecourt levels whilst eliminating load transfer from the cover to the tank.

All OPWlite products are manufactured in Europe under the watchful eye of the OPW technical team, ensuring consistent quality.

For more information on the OPWlite range, please visit OPWlite.com

Related links

Categories

OPW is a global leader in fluid handling, management, monitoring and control solutions for the safe and efficient handling of fluids from the refinery to the commercial and retail points of consumption, including loading systems, rail and transport tank truck equipment, tank gauging, fuel management systems, valves, fittings, underground and above ground storage tank equipment, spill containers, overfill prevention devices, secondary containment sumps and flexible piping, commercial and retail fueling dispensers and electronic POS systems, swivels, breakaways, and nozzles for virtually all fuel types, including LPG, Hydrogen and CNG. OPW also designs and manufactures touch-free and friction car wash systems. OPW has 3,850+ employees with manufacturing operations in North America, Europe, Brazil, China and India and sales around the world.