Blog post -

Corrosion in gaseous environments – part I

One of the causes for faulty Airec heat exchangers is corrosion. Since nearly all literature on corrosion concerns liquid environments, has Airec spent quite some time and resources to understand and prevent corrosion in gaseous environments at temperatures below ca. 700 ⁰C (at higher temperatures a different phenomenon called hot corrosion can occur).

Why do metallic materials corrode?

The scientific answer is that the material wants to return to its thermodynamical stable state. This means that the metal strives to react with its environment in order to return to the form (the ore) it is found as in nature, i.e. oxides, -O, sulphates, -SO4, sulphides, -S, or carbonates, -CO3.

The material wants to lower its intrinsic energy, the driving force for the corrosion process are electrochemical and thermodynamical.

For corrosion to occur, the formation of a corrosion cell, is essential. Such a cell consists of four parts:

- Anode – the negative terminal of the cell, electrons are donated via oxidation. This is the point where the metal dissolves.

- Cathode – the positive terminal of the cell, electrons are accepted via reduction. This is the point where there the anion (e.g. sulphate) is formed.

- Electrolyte – An electrical conductive solution (e.g. aqueous salt solution) which provide connection between the terminals via ion conduction.

- Metallic path – The two electrodes (anode and cathode) are connected externally by a metallic conductor.

All parts are essential, take away one, and the corrosion stops. This implies that for corrosion to occur in the applications of interest for Airecs heat exchangers there must be a condensation of an electrolyte onto the gas side surfaces of the heat exchanger. Theoretically can all the types and mechanisms of “normal” wet corrosion occur in a gaseous environment if there is some form of condensation. In gas-to-liquid heat exchange in a brazed plate heat exchanger, BPHE, are the possible types of corrosion limited due to the materials and the operational conditions.

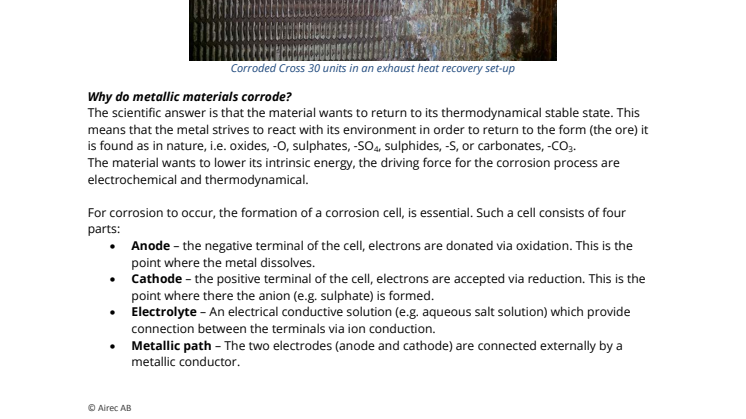

Corroded Cross 30 units in an exhaust heat recovery set-up

The types of corrosion which has been seen by Airec in claim cases are:

More details, and short explanations on the types of corrosion, in part II.

Gas side corrosion in a BPHE occurs on the surfaces. In surface corrosion can the electrodes (the anode and the cathode) be regarded as surfaces. For a corrosion cell to form these surfaces must be wetted by an electrolyte (condensate) with sufficient ionic strength to electronically connect the two surfaces (ion conduction is a slow process and therefore rate determent). The latter implies that if the condensate is not rather acidic (pH < 5) or basic (pH > 10) is the presence of a reductant, which can dissolve in the condensate (e.g. oxygen, O2), in the gas stream needed. These demands on the condensate film on the surface means that the thickness of the condensate film should have an impact on the corrosion rate. According to literature is this at least true for atmospheric corrosion, there an optimum thickness of condensate for the corrosion rate exists.

Rate of atmospheric corrosion as a function of water film thickness (Bardal, 2004)

In a properly installed Airec BPHE, operated in a suitable environment and at reasonable conditions (more on these limitations in part II), should corrosion not occur. Still, there have been reported cases of corrosion. There is one thing in common for nearly all of these cases, there has been some form of precipitate on the surfaces. The precipitate has created patches where the condensate has had stagnant flow conditions and therefore had necessary time and micro environment for the corrosion cell to activate and the corrosion to do its harm.

The trouble is that it is difficult to predict a precipitation already in the design phase of a heat exchanger installation, the origin for the precipitating species can in some cases be found several steps upstream in the installation. We will in the next part give some general tips on which substances to look out for, to avoid corrosion issues.

Corrosion is a quite complex and advanced know-how which to large instance is based on experience. Airec have over ten years of experience on heat recovery from hot flue gases. Based on this experience I will try to give an explanation to how and why the four different types of corrosion mentioned above occurred by examples in the next part.

Related links

Topics

- Studies

Categories

- värmeväxlare

- korrosion