Pressmeddelande -

Areas where UV laser cutting systems are used, LPKF laser & Electronics AG

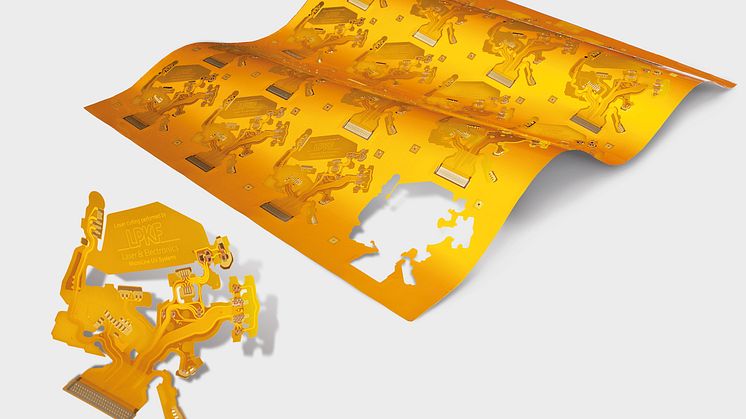

UV laser cutting systems show their special strengths with small,

thin and flexible circuit carriers. Depending on the thickness of

the circuit board material, one or several cuts along the desired

contour are required. The thinner the material, the quicker the

cutting process goes. If fewer laser impulses are emitted than

are required for penetrating the material, engraving of the

substrate takes place. In this way, clear component markings

for tracking & tracing can be applied during the separation

process.

Flat materials can be easily held in position by a vacuum table,

since the cutting process has no mechanical effects on the

material to be cut. For protection of strip conductors, cover layers

are applied to flexible interconnect devices. They often consist of

polyimide and glue with a thickness of 25 µm or 12.5 µm and are

sensitive to deformations. Individual areas – e.g., soldering pads

– have to be separated from the cover layers. This processing is

also one of the strengths of UV lasers.

For cutting entire contours, LPKF recommends a maximum thickness

of 0.8 millimeter; for webs, up to 1.0 millimeter. By means of multiple

cutting, noticeably larger material thicknesses are also possible –

with sensitive and valuable circuit boards, the longer cutting times

recede into the background compared to the safety and quality

aspects.

That also applies to decap applications and pockets in multilayers:

the UV laser cuts rigid and flexible components or extracts areas

from multilayer circuit boards so that components can be embedded

flush with one another. Technically this is no problem if the area of

the pockets is not laminated. The penetration depth of the UV laser

can be controlled so precisely that layers underneath are not

damaged.

Läs mer...

Contactperson in Sweden: Mr. Gerhard Tetzlaff

Phone: +46-40-536614, E-mail: gerhard.tetzlaff@solectro.se

--------------------------------------------------------------------------------------------

Ämnen

Kategorier

Regioner

Solectro AB grundades 1983 av Gerhard Tetzlaff.

Verksamheten omfattas av utveckling, produktion, försäljning och service av komponenter för automatisering, komplettlösningar, specialmaskiner, robotar, CNC-maskiner,PCB-prototying, laser, SMD samt dentalmaskiner.

Solectro AB är beläget i Lomma - ca. 10 minuter från Malmö och Lund.

Adress:

Tenngatan 6 - 8, 234 35 LOMMA

Tel. 040-536600

Fax 040-536610

E-mail: solectro@solectro.se

www.solectro.se