News -

Marine and industrial engineering firm migrates to SAP Business All-in-One for a more fluid business processing system

Singapore has one of the world’s busiest seaports, and is renowned globally for its wide range of quality, efficient, and reliable marine services. A key component of this dynamic sector includes the marine construction and engineering industry where companies like Chong Lee Leong Seng Co Ltd (CLLS) is one such essential part of the market ecosystem.

From just a trading company distributing Yanmar diesel engines in 1959, the 200-staff strong CLLS now boasts a present-day portfolio that includes import and export, warehousing, and after-sales services. The company is not just a leader in marine engineering; it is also well-known in the industrial and agriculture, construction and building as well as power generation sectors.

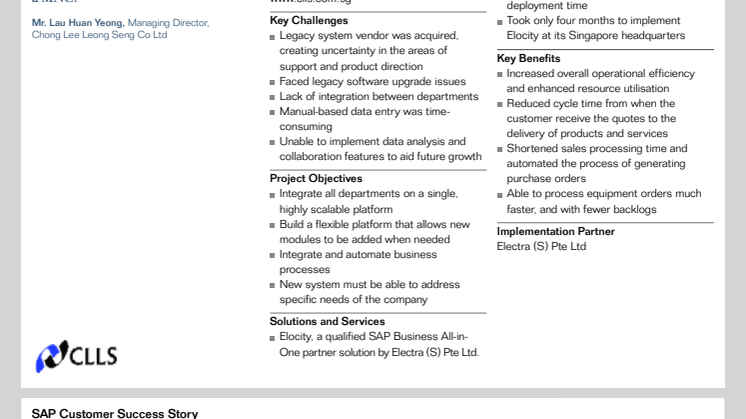

In this increasingly competitive industry, however, it is crucial for CLLS to optimise its operations and communicate with its clients and principals in the most cost-efficient manner. Yet CLLS’ legacy system was hindering its ability to achieve its vision.

“We have evolved from just a trading company based in Singapore to a global distributor with presence worldwide. For a company with so many branch offices in different countries, connectivity between operations is critical,” says Mr. Lau Huan Yeong, Managing Director, CLLS.

“We need to be able to replicate and synergise our business strategy across the company. Our old business software was unable to help us achieve this vision and that was why we needed a new, more powerful and flexible platform.”

Replacing an Inefficient System

Problems surfaced when the software vendor of its legacy system was acquired in 2004. There was also a lack of visibility on the system’s future direction which created a lot of uncertainty in how CLLS would be

supported. Additionally, the company was facing legacy software upgrade problems, and owning a customised service module further complicated the process.

Another issue that compounded the problem was the lack of integration between the different modules in the old system, which affected data visibility across the enterprise. For instance, the service module was not linked to the financials module, preventing CLLS from determining the labour costs associated with each after-sales service job it takes on. As a result, this affected the management’s ability to identify all the operating costs and tasks associated with servicing clients. Staff productivity was impacted too, as they had to re-enter relevant data into their own departmental system.

In addition, the legacy system was limiting CLLS’ future plans to enhance operational excellence. For example, it would affect the company’s ability to collaborate with its principals and customers, and prevent them from implementing business intelligence to conduct data analyses which would aid the management in decision making.

Strong Products, Great Chemistry

Several solutions were short listed by CLLS during its stringent six-month evaluation process. However, SAP stood out with its ability to address the company’s needs from end-to-end, and especially the “service” module which fitted its operating requirements.

Finally, the company selected Elocity, a qualified SAP Business All-in-One partner solution, developed by Electra (S) Pte Ltd – an SAP channel partner. The Elocity solution is tailored to address the unique operating and production requirements of industrial machinery and components (IMC) manufacturers and distributors.

“When your company aspires to grow, you can’t have a platform that doesn’t allow you to scale. SAP allows us to think big. We hope with SAP, it will take us from a local small and medium enterprise to become a MNC,” says Mr. Lau.

“SAP’s long-standing reputation in providing reliable solutions played a huge part in the management's decision. There was also chemistry between CLLS and Electra, and that was an important criterion for us when selecting our implementation partner.”

A Fail-Safe Approach

Elocity went live at the company’s Singapore headquarters in June 2006 after a short four-month implementation process.

CLLS used the template-based methodology of SAP Best Practices to shorten the implementation timeframe. Another strategy that ensured project success was management buy-in, says Mr. Roger Tan, IT & Logistics Manager, CLLS.

“Using SAP Best Practices gave us the confidence that the solution would work for us. And as it was a complete makeover for the company, we ensured that our users were constantly motivated by the management to adopt the new system,” adds Mr. Tan.

Faster, Better, Stronger

Looking at what CLLS has achieved through SAP and Electra, Mr. Tan declares, “You cannot go wrong with SAP. The benefits we have reaped so far have only confirmed that we made the right decision to go with SAP Business All-in-One solution.”

Since the implementation of Elocity, all of CLLS’ business processes have become well-integrated on a single platform, delivering the operational efficiency and resource optimisation that the company has aspired.

Now, the quotation and sales order processing time have reduced significantly as they are integrated and automated seamlessly to both the finance and sales departments. Customer service has greatly improved as it takes a much shorter time now to respond to customer queries and fulfill orders than in the past.

Furthermore, the material management module gives the warehouse department more time to focus on checking and picking of goods rather than data entry.

And for cross-docking operations, the new system is able to help identify and segregate incoming goods by customers, resulting in faster receiving and delivery time. The search function of the system is also easy to use, allowing users to find information efficiently.

Achieving More with a Strong Foundation

The company is already looking towards implementing SAP NetWeaver Business Intelligence. With this, CLLS hopes to address its reporting requirements, and in turn improve the business decision-making process.

The company is also planning to explore how it can improve inventory management and communications with its suppliers and dealers with the help of SAP.

“There is a lot more that we want to achieve as a company, and with SAP and Elocity, we know that we have the right foundation to success. SAP is indeed one of the best, if not the top, in providing solutions for small and medium enterprises,” adds Mr. Lau.

Related links

Topics

- Motor

Categories

- chong lee leong seng

- clls

- marine engineering

- construction

- industrial

- power generator

- sap business

- lau huan yeong

- elocity

- electra