Digital meetings gave the manufacturing industry a boost

400 meetings over the course of four days. Close to 300 suppliers and 70 buyers from 26 countries. These are the figures that made up Elmia Subcontractor Connect, which ended on 13th November.

400 meetings over the course of four days. Close to 300 suppliers and 70 buyers from 26 countries. These are the figures that made up Elmia Subcontractor Connect, which ended on 13th November.

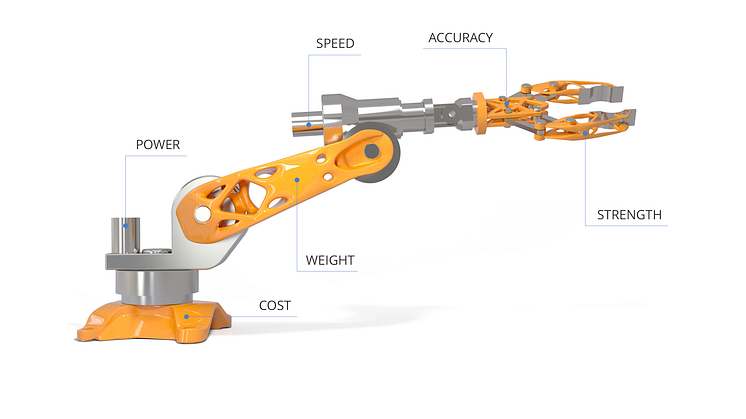

Simulation-driven product development opens up brand new opportunities for innovation – in all sectors. This is the opinion of Altair, a new exhibitor at Elmia Subcontractor this autumn.

Through the newly established Elmia Spark Award, Elmia and Fairlink want to drive exhibitors and visitors return on event (ROE) to new heights. Now Jason Popp, at GES, agreed to join the jury. With more than 90 years and the most comprehensive breadth of services and technology, GES bring brands and customers closer together through events, exhibits and exhibitions.

The superheroes of steel. That has been a focus for SSAB during this year’s Elmia Subcontractor. The company’s presence at the fair has also been a great success with almost 400 leads in the first three days alone.

No rot and no need to repaint. Interest in wood-plastic composites is growing and the Swedish company A-Plast has developed a material all of its own. At Elmia Subcontractor visitors have asked many questions about the technology involved.

SKF is launching a series of new products on the Swedish market at Elmia Subcontractor 2017. The focus is on efficient rotation and increased operational safety.

Perseverance pays off. The Italian company Ma. Bo. is exhibiting this year at Elmia for the fifth time and sales manager Pierluigi Casadei has seen strong growth for the company. “It gets better and better every year,” he says.

Better design possibilities and greater efficiency – using a light guide plate equipped with LEDs has many advantages. The Danish company Ingemann Components is presenting the possibilities and the solution at Elmia Subcontractor.

The Internet of Things offers new opportunities to Swedish industry. One step towards success is to become more transparent as a company and exchange ideas with others. One such example is the joint venture Combient, which visited Elmia Subcontractor and took part on stage under the theme “The IoT is creating opportunities for new products and business deals”.

Steel producer Ovako has a tradition of launching major new products at Elmia Subcontractor. This year the company is presenting its innovative Hybrid Steel®. “It’s a new steel family with unique properties,” says Jukka Kivelö, Ovako’s sales manager for Scandinavia.

Start by creating an awareness in your company about new technology. Then dare to try out your ideas. That advice was given by Benny Guttman at Elmia Subcontractor and it focuses on the technological shift we are currently experiencing.

It is obvious that the Internet of Things can create new business applications for the manufacturing industry. But the IoT can also help the world’s climate. The Swedish company WSI has developed an environmental sensor that collects weather data from 30 cities around the world. The solution can be seen at Elmia Subcontractor.

Sensors on rubbish containers can help a recycling company make major energy savings. The solution was developed by the Finnish success company Enevo with help from Arrow Electronic. At Elmia Subcontractor Arrow is showing how the system functions in real life.

It began in 2012 as a small-scale research project. Today it is a rapidly growing environmental venture. All thanks to ordinary hemp. “Using natural fibre as reinforcement instead of glass fibre and carbon fibre is both strong and environmentally sound,” explains Jeremiah Dutton of Trifilon, exhibitor at Elmia Subcontractor for the first time.

Hydrogen trains or battery-powered ones? Both options can replace diesel trains in the future. But why is a change necessary? These issues were discussed during the seminar “Higher, longer, lighter hybrids – What is the look and feel of the future trains?”

Is building a high-speed rail line in Sweden the solution to every problem? That somewhat pointed question was discussed at the key seminar “High-speed railways – do they solve the problems?” The panel’s answer? They don’t solve everything but they help a lot.

Establish a Nordic transport plan. That was the clear message from the sector during Wednesday’s key seminar at Elmia Future Transport, Industry’s Vision for Better Transport in the Nordic Region. “The national transport plans only extend as far as the borders – and barely that,” said Are Kjensli, Director of NHO Logistics and Transport.

The process is far too slow. This is according to Yu Xing, Chief Engineer at Siyuan’s International Business department – and he is of course talking about high-speed tracks in Sweden. “We could build them in five years,” he says.

Buses, routes and keeping to a tight timetable have always been the main priorities. But during the seminar entitled Who owns the relationship with the passenger?, the focus was firmly on the customer. - Once we’ve expanded public transport as far as possible, the industry is quite widely agreed that the next step is customer orientation,” said Henrik Dagnäs, Head of Marketing at Nobina.

This year, Elmia is broadcasting its key seminars live online for anyone who can’t be in Jönköping.