Online showcase event - Leine Linde encoder news 2022

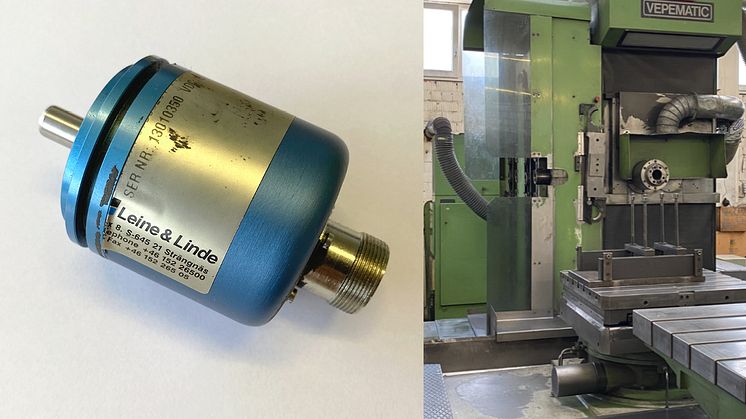

On January the 27 our product management team presented last years product highlights on a digital broadcast from our flagship showroom at our HQ in Strängnäs, Sweden.

Topics on the broadcast:

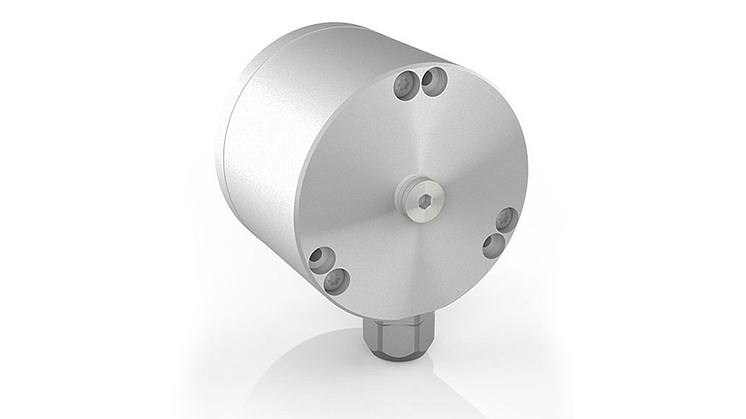

Encoders with added features:

Encoders for functional safety

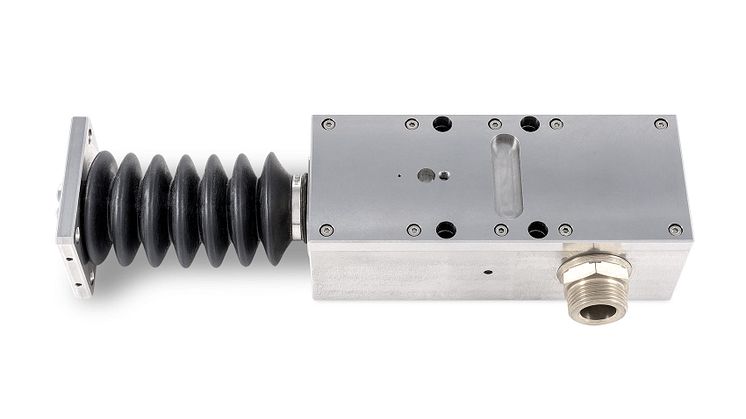

Condition monitoring solutions for increased uptime

EX certified encoders

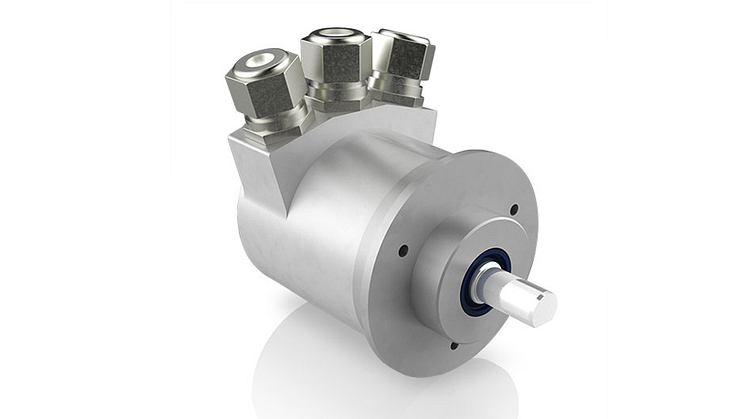

Encoders for large (and very large) drives.