Press release -

Graphene enables ten times higher data storage in computer memories

Researchers at Graphene Flagship Partners the University of Cambridge, UK, Ecole Polytechnique Fédérale de Lausanne (EPFL), Switzerland, Empa-Swiss Federal Laboratories for Material Science and Technology, Switzerland and Graphene Flagship Associate Member the University of Exeter, UK, in collaboration with colleagues at CSIR-Advanced Materials and Processes Research Institute, India, National University of Singapore (NUS), A*STAR (Agency for Science, Technology and Research), Singapore, the University of Illinois and Argonne National Laboratory, US, have demonstrated that graphene can be used to produce ultra-high density hard disk drives (HDD). This can lead to the development of ultrahigh density magnetic data storage: a big jump from the current one terabit per square inch (Tb/in2) to ten terabits over the same area.

HDDs first appeared in the 1950ies, but their use as storage devices in personal computers only took off from the mid-1980s. They have become ever smaller in size, and denser in terms of the number of stored bytes. While solid state drives are popular for mobile devices, HDDs continue to be used to store files in desktop computers, largely due to their favourable cost to produce and purchase.

HDDs contain two major components: platters and a head. Data are written on the platters using a magnetic head, which moves rapidly above the platters as they spin. The space between head and platter is continually decreasing to enable higher densities. Currently, carbon-based overcoats (COCs) – layers used to protect the platters from mechanical damages and corrosion – occupy a significant part of this spacing. The data density of HDDs has quadrupled since 1990, and the overcoats’ thickness was reduced from 12.5nm to about 3nm, which corresponds to one Tb/in2. However, a COCs’ thickness of less than one nm would be required to make a significant improvement in data storage and reach a density of 10 Tb/in2.

Since the current COCs lose most of their appealing properties under 2nm, Graphene Flagship researchers replaced them with 1 to 4 layers of graphene, and tested friction, wear, corrosion, thermal stability and lubricant compatibility. Beyond its unbeatable thinness, graphene fulfills all the ideal properties of an HDD overcoat: corrosion protection, low friction, wear resistance, hardness, lubricant compatibility and surface smoothness. The researchers verified that graphene enables two-fold reduction in friction and provides better corrosion and wear than state-of-the-art COCs. A single graphene layer reduces corrosion by 2.5 times, and multilayer graphene showed excellent performance with a decrease of wear rate by three orders of magnitude.

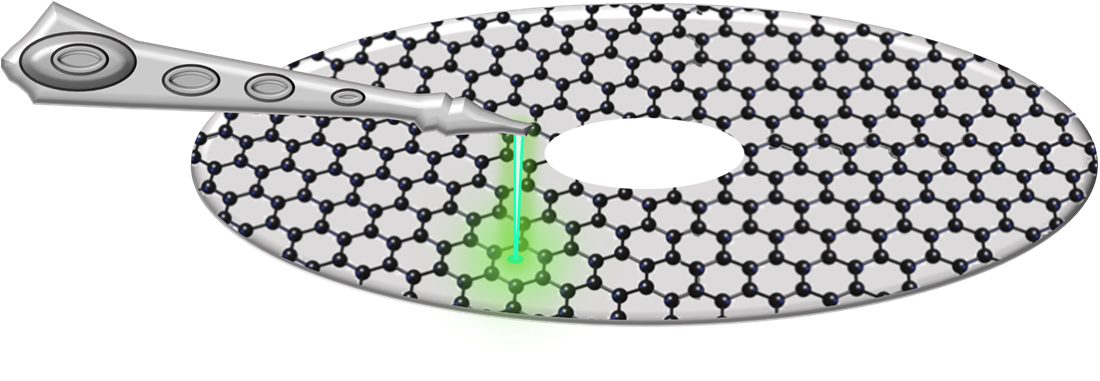

Schematic showing the hard disk covered with graphene. For heat-assisted magnetic recording, a laser is used to heat up the magnetic recording layer to make it writeable with a conventional read/write head. Credit: Anna Ott

1-4 layers of graphene were grown via chemical vapour deposition (CVD) and transferred on Co-alloy hard disk substrates as those used in current HDD technology. The Graphene Flagship researchers also transferred graphene on hard disks made of iron-platinum (FePt) as magnetic recording layer, to test Heat-Assisted Magnetic Recording (HAMR) – a new magnetic storage technology that enables an much higher storage density than currently available, by heating up the recording layer to high temperatures. Current COCs do not survive HAMR’s high temperatures, but stability tests confirmed that graphene can withstand HAMR-like conditions, without degradation. Thus, graphene-based overcoats used in combination with innovative technologies, such as HAMR and bit patterned magnetic recording (BPM) – a method to pattern the magnetic media in small pillars which enables high areal density – are expected to outperform current HDDs providing an unprecedented data density of 10 Tb/in2 or more.

“Demonstrating that graphene can serve as protective coating for conventional hard disk drives and that it is able to withstand HAMR conditions is a very important result. This will further push the development of novel high areal density hard disk drives,” says Anna Ott, from the Cambridge Graphene Centre, one of the authors of this study, currently based at the Graphene Flagship Associate Member the University of Exeter, UK.

Mar García-Hernández, Graphene Flagship Leader for Enabling Materials, says: “A jump in HDDs’ data density by a factor of ten and a significant reduction in wear rate are critical to achieve more sustainable and durable magnetic data recording. Graphene based technological developments are progressing along the right track towards a more sustainable world.”

Andrea C. Ferrari, Science and Technology Officer of the Graphene Flagship and Chair of its Management Panel, adds: “This work showcases the excellent mechanical, corrosion and wear resistance properties of graphene for ultra-high storage density magnetic media. Considering that in 2020, around 1 billion terabytes of fresh HDD storage was produced, these results showcase the potential of graphene for the mass market. Yet again, the Graphene Flagship is at the forefront of the development of cutting-edge technologies.”

Reference

Dwivedi et al. “Graphene Overcoats for Ultra-High Storage Density Magnetic Media.” Nature Communications, 2021, 12, 2854, DOI: 10.1038/s41467-021-22687-y.

Topics

Categories

About the Graphene Flagship

The Graphene Flagship is research, innovation and collaboration.

Funded by the European Commission, the Graphene Flagship aims to secure a major role for Europe in the ongoing technological revolution, helping to bring graphene innovation out of the lab and into commercial applications. The Graphene Flagship gathers nearly 170 academic and industrial partners from 22 countries, all exploring different aspects of graphene and related materials. Bringing diverse competencies together, the Graphene Flagship facilitates cooperation between its partners, accelerating the timeline for industry acceptance of graphene technologies. The European Commission’s FET Flagships enable research projects on an unprecedented scale. With €1 billion budgets, the Graphene Flagship, Human Brain Project and Quantum Flagship serve as technology accelerators, helping Europe to compete with other global markets in research and innovation. With an additional €20 million investment, the European Commission has now funded the creation of an experimental pilot line for graphene-based electronics, optoelectronics and sensors.