Is there such a thing as “Too Good” of a Precision Shaft Alignment?

This question comes up frequently in our Shaft Alignment Best Practices training classes. The result screens below both show two different aligned machines meeting 3600 tolerances.

This question comes up frequently in our Shaft Alignment Best Practices training classes. The result screens below both show two different aligned machines meeting 3600 tolerances.

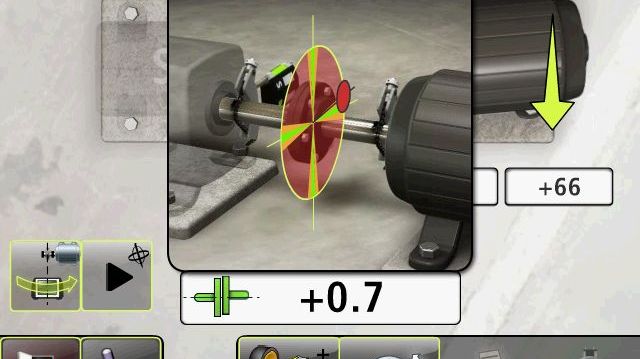

A recent Fixturlaser NXA Pro training class performed an alignment check of a winch driven by an 80 HP, 1800 RPM, DC electric motor with a gear style coupling. The initial results revealed a misaligned machine, with a vertical angularity over 13 times the tolerance of 0.7mils/1” (1.0 mil = .001”), vertical offset six times tolerance of 4.0 mils. The horizontal angularity was almost 4 times to

By Tom Shelton, Vibralign

Proper use of any tool is essential to success in achieving your desired goal. Many tools have optional configurations to adapt that tool to your needs. Fixturlaser Precision Alignment Systems are no different. The alignment tools produced by Acoem/Fixturlaser are second to none in ease of use. The Acoem AB design engineers do all they can to provide the end user with

By Mac MacCormack , Vibralign

From the editor – Trainers see many different machinery base designs and installations during the OJT portion of our training classes. Some bases are quite substantial while others are flimsy and actually downright horrible Poor bases have a negative impact on rotating machinery reliability and can certainly be a cause of precision shaft alignment frustration.

OL2R is the acronym for OffLine 2 Running. OL2R is an optional program and special precision bracket set that is available for the Fixturlaser NXA Pro & Ultimate. This option allows the shaft aligner to accurately measure vertical AND horizontal changes of machines from a static (OffLine) position to a Running position.

This allows for very precise targeting of rotating machinery durin

By Steve Gordon on April 28, 2016, Vibralign

I was asked to help a customer align a 500HP Motor / Blower. The new motor came in on a skid, was lifted into place with a crane, new electrical boxes fitted and coupling put into place. Now the easy part, the precision shaft alignment!

We took two sets of measurements which repeated. Made one small shim correction (The motor was roughe

Det går bra för oss! För att möta våra kunders behov vi förstärka med en Elektronikkonstruktör. Vår kultur präglas av stark utveckling, teknisk kunskap och professionalism. Vill du ta ditt nästa steg i din karriär och arbeta i ett mindre företag som ingår i en större internationell koncern, ser vi fram emot din ansökan.

Arbetsuppgifter

Dina huvudsakliga arbetsuppgifter är att:

- utvec

We recently received a customer request about shim safety. An employee at the customer site had experienced a “near miss” safety issue due to walking too closely to a machine, and getting their clothes caught against a shim. Since I have a scar on my right thumb caused by a 3 mil shim, I thought a discussion on shim safety might be in order!

Shims do three things:

Change the elevation of

By Brad Case on January 25, 2017 Vibralign

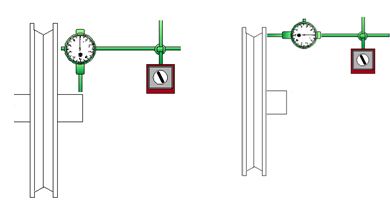

When training clients to use Fixturlasers Verti-Zontal Alignment Process we show taking the 3rd measurement at a horizontal position, typically at 3 o’clock. This is simply for expediency and is NOT a requirement as Fixturlaser Shaft Alignment Systems can take measurements at any position due to the inclinometers in M & S sensors.

If possible we

Published by vibralign.com

Belt Alignment

Belt alignment, or more accurately sheave alignment, is the process of achieving proper radial and axial alignment of the centerlines of sheave grooves, onto which belts run. Historically, belt or sheave alignment has not been considered a major concern in maintenance, due to belt costs being relatively small. How

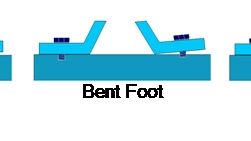

Throughout our 2015 Realigning America Tour, our distributor, VibrAlign spoke with maintenance industry professionals in 18 cities, there was one common problem that we were asked about at every single stop: soft foot. One of the arch nemeses of precision alignment, soft foot can occur before or after the alignment process; right when you think you’ve brought your machine within tolerance, yo