The Cure for Alignment Frustration!

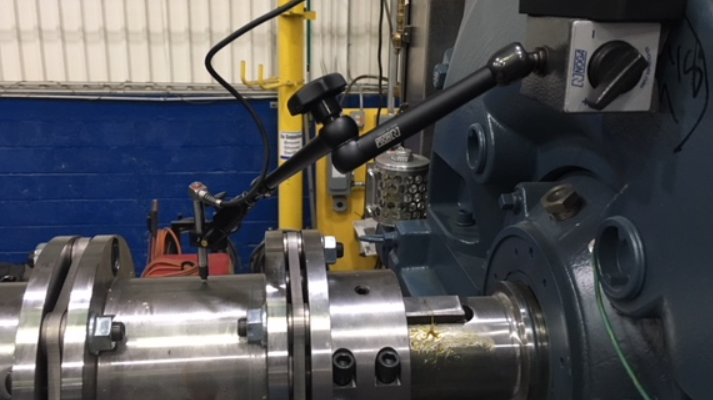

When laser alignment tools are not repeatable, it’s not the laser – IT’S YOU.

When laser alignment tools are not repeatable, it’s not the laser – IT’S YOU.

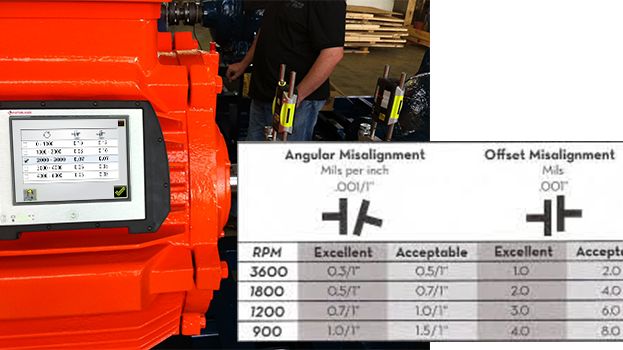

The initial set of alignment results indicated horrible angular misalignment (14 to 16 times tolerance) and offset misalignment (6 to 8 times tolerance) in the vertical and horizontal planes

Thermal growth is not rocket science. However, it is often misunderstood. We see people causing harm by compensating for thermal growth incorrectly.

The Fixturlaser SMC is designed to be used by machinery mechanics to give a clear and accurate automatic diagnosis of rotating equipment. Requires no vibration expertise or internet connection.

The Fixturlaser SMC is a powerful machinery diagnostics tool that requires no vibration expertise. After the user has built their machine in the box, the SMC will diagnose the machine's faults in a matter of seconds utilizing the Accurex automatic diagnosis software.

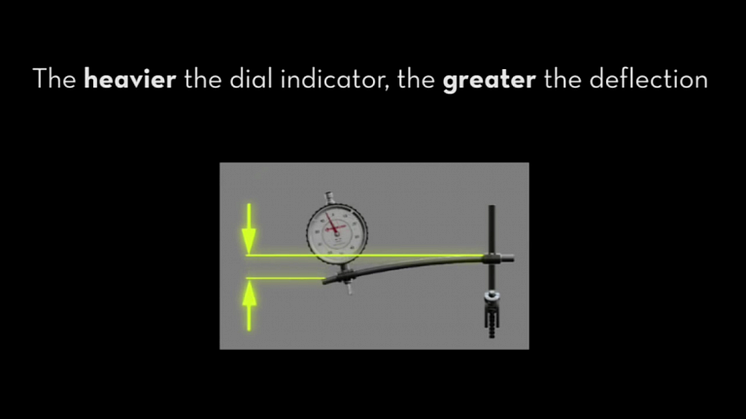

Dial indicator bar sag describes a bending of the hardware used to support a dial indicator or other part which spans the coupling. The bending action occurs as a result of gravity and cannot be totally eliminated in almost all cases of alignment.

Fixturlaser have done what we will to form the exactness shaft alignment method faster and easier for the user of our tools. To help maintenance personnel throughout alignment a tolerance table “pops up” on the unit screen (of our tools) once getting into dimensions for the machines being aligned. The tolerances square measure supported industry standards.

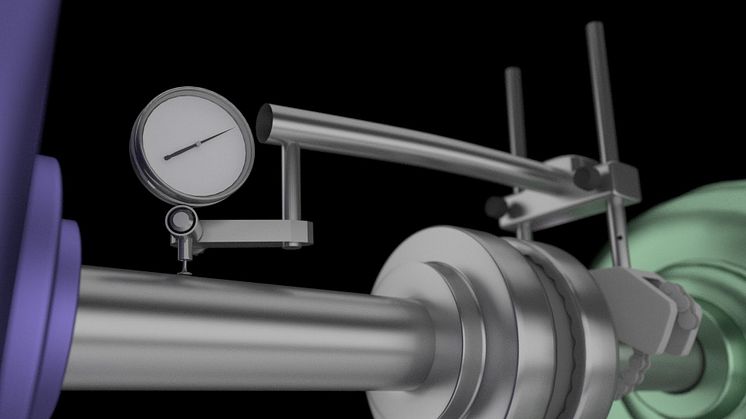

The Runout Probe provides a digital linear displacement measurement, much like a dial indicator, but with the added benefit of electronic documentation through the Bluetooth connection with the NXA Display Unit.

Hold down bolts are designed to keep the machine in position after a precision alignment is performed. Jacking bolts are designed to help position a machine during the alignment. Jacking bolts are not designed nor should be used to maintain the position of a machine, that is the job of the hold down bolts. Let’s look at the design intent of each type.

So what is bar/rod sag? Simply put, it is how much the dial indicator mounting bar deflects when the rim dial indicator is install. How much the bar/rod deflects depends upon the type of bar (solid or tube), the length of the bar and weight of the dial indicator.

Unbalance and runout are two terms that we hear frequently in the predictive maintenance community. Both unbalance and runout can be serious issues and need to be addressed to prevent inefficient functioning and damage to machines.