Using the Verti-Zontal Process on Wind Turbines with Adjustable Chocks

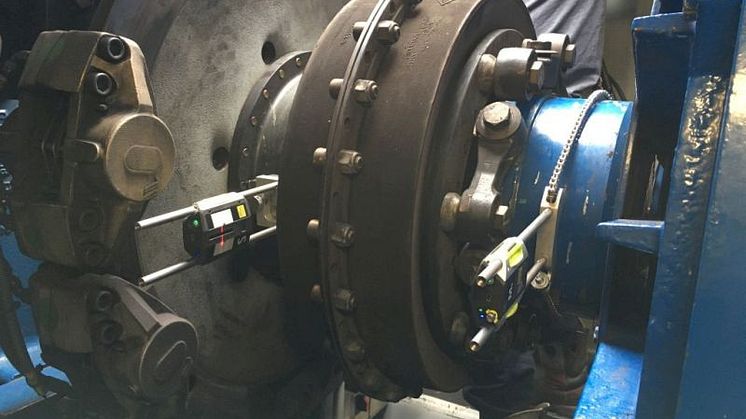

Precision shaft alignment of wind turbine generators mounted on adjustable chocks is as straightforward as when aligning rotating machinery mounted on chocks down at ground level.

In the case of a recent NXA Training Class in a Vestas V82 we knew before going up-tower that one revolution of the adjustable chocks equals 1mm. Also, as there are 6 holes in the chocks, we calculated that the hole t