Why and How to Measure in Clock Method

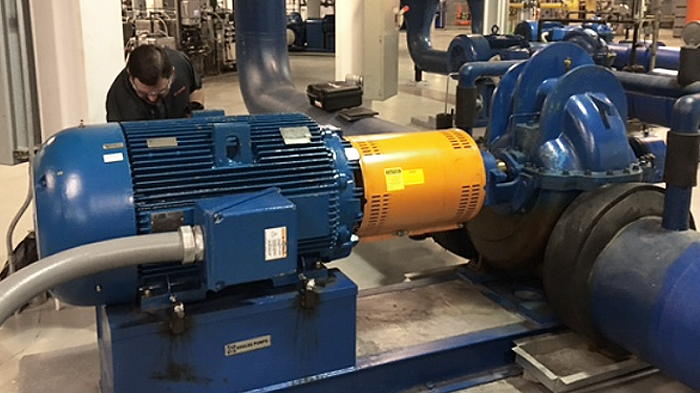

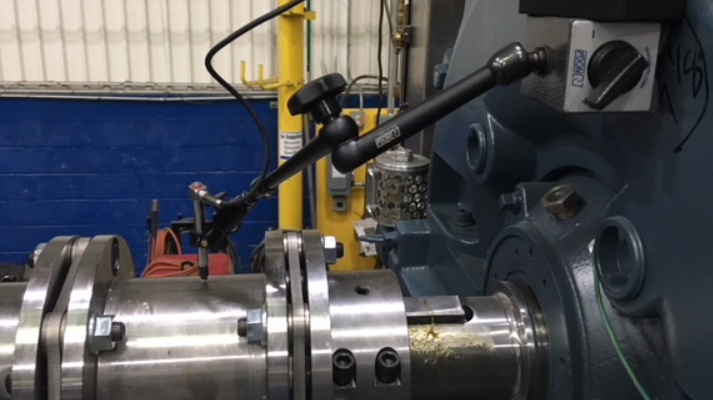

Proper use of any tool is essential to success in achieving your desired goal. Many tools have optional configurations to adapt that tool to your needs. Fixturlaser Precision Alignment Systems are no different. The alignment tools produced by Acoem/Fixturlaser are second to none in ease of use. The Acoem AB design engineers do all they can to provide the end user with an alignment tool that can be