Fixturlaser LEVEL

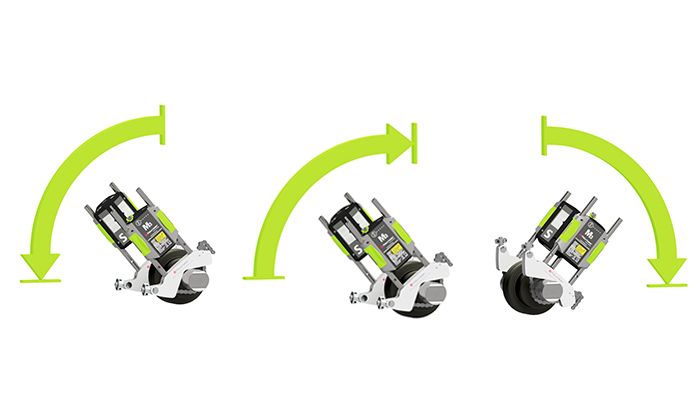

Fixturlaser LEVEL is used for levelling machines or machine parts during installation and gives accurate measurement results. The measuring sensor measures the angular deviations from the surface in two axes using a wide measurement range (± 50 mm/m), high accuracy and with a resolution down to 0.01 mm/m.