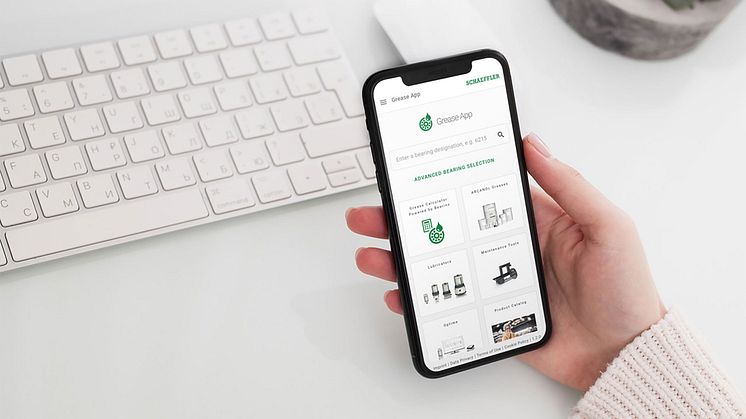

Schaeffler Grease App: More efficient and sustainable rolling bearing lubrication

Up to 80 percent of all premature bearing failures are caused by incorrect lubrication. This is where the Grease App from the automotive and industrial supplier Schaeffler comes into play for the customer by determining the ideal lubricant type, lubricant quantity, grease service life, and relubrication intervals required for initial lubrication and relubrication of the rolling bearings.