Pressmeddelande -

LPKF - Boosting efficiency with laser plastic welding

Lasers have gained an excellent reputation for joining plastic components together. They create very efficient joints and boast qualitative as well as economic benefits. Please see the article on the current state-of-the-art for laser plastic welding below.

Joining plastic components is something that has exercised the minds of industrial experts for more than half a century. The search for economical methods to join components became urgent with the development of injection moulding. And even today, the majority of all plastic products still cannot do without a joining process which seals the component after assembly.

In the early days, this was frequently done with screws, or the parts were simply glued together. These methods are comparatively expensive and time-consuming. The development of more economical and reliable joining techniques suitable for production lines was given a major boost when the automotive industry began to build more and more plastic components into their vehicles. This gave rise to the development of plastic welding.

High energy density

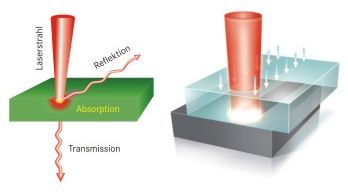

During metal welding, two parts are welded together by heat and pressure. The same applies to laser plastic welding, but with one big difference: the laser energy is not usually effective on the top surface of the component but only precisely where the welding seam is required. How is this possible?

Because a laser works with light, the laser beam can be concentrated with lenses, and guided by mirrors or fiber optic cables. This transmits the energy to the workpiece.

An important aspect is that not all of the laser energy becomes effective. The energy which is beamed-in is partially reflected, partially transmitted through the component, and partially absorbed. Only the absorbed portion of the laser energy becomes effective as it is converted into heat. A high energy density can be achieved even with a relatively small laser capacity. The laser beam is focused onto a point only a few micrometres in diameter. The energy density at the focus of the laser beam can easily exceed that on the surface of the sun.

Different welding methods

In the transmission laser welding technique, the process depends on having a laser- transparent material and a laser-absorbing material. The laser light passes through the upper laser-transparent component with almost no absorption and melts the surface of the underlying laser-absorbing component. The application of a precisely calculated amount of pressure guarantees good thermal conduction so that the underside of the upper component also melts.

This principle is used in a variety of welding methods, and has led to the development of optimal welding processes for a range of products.

In the simultaneous welding method, the whole welding seam is warmed up simultaneously by a laser beam. This method requires very homogenous distribution of the output density – even around corners and over changes in height. It needs the application of several lasers or special masks and is now only used when extremely high production volumes are involved.

The quasi-simultaneous welding technique works in a similar way, but in this case, a laser beam runs along the contour repeatedly until the specified welding result has been achieved. The rapid movement of the laser beam gives rise to the quasi-simultaneous plastification of the whole welding seam. One of the advantages is that this enables the melt-travel to be controlled and can thus compensate for tolerances in the injection molded parts being welded together.

In the contour welding technique, the laser moves relative to the component. Only a small part of the welding seam is melted at any given time. Contour welding is particularly good when rotation-symmetrical or very large components have to be joined together without any melt blow-out.

Plastic welding: an innovative joining process

A whole range of different welding methods has been developed for production processes. The first plastic welding technique to be developed was the hot-element method. This was followed by the development of ultrasonic and vibration welding. Laser plastic welding is the most modern development. The main difference between these technologies is the way the energy is applied.

Today, the following methods are commonly used in production lines:

- Friction welding (vibration and rotation welding)

- Ultrasonic welding

- Microwave welding

- High frequency welding

- Heating-element welding

- Laser plastic welding.

Every method has its own special advantages and disadvantages. The selection of the method partly depends on the properties of the plastics which are used, as well as the application and the associated specifications.

Restricting the energy precisely to the welding zone

In heating-element welding, the plastic touches a heated plate. This method is unsuitable for plastics which could stick to the heating element. Vibration welding is only possible on components which are almost completely flat because the relative movement between the components would otherwise cause serious damage. The process involved in friction and ultrasonic welding automatically gives rise to the formation of particles around the welding seam.

Laser welding suffers from hardly any of these process-related restrictions. And in addition to the very wide range of application areas, this method also has other qualitative advantages which makes its use even more attractive – for instance, the energy can be restricted very precisely to the welding zone.

Modern laser welding machines are gaining more and more ground because the price of laser sources is continuously sinking and the development of new process methods opens up many new options. This gives rise to the continuous development of new applications. None of the other welding methods available today can boast such a huge application variability.

IN FOCUS

Large free-form components

Large components such as car taillights are a very challenging joining problem, particularly when they involve difficult material combinations and visible seams. The robot-assisted LPKF TwinWeld-3D welding system combines a halogen lamp and a laser beam to join together any type of free-form components. The compact head sits on a robot with seven degrees of movement. No special clamping tool is required because the necessary pressure is supplied by a special pressing device attached to the head. All this means minimal tool costs and the highest welding seam quality without any damage to the surface and the visible areas. These systems are currently used to weld car taillights. Other large components such as solar modules and containers are in the pipeline to utilize this technology for serial production.

Continuous improvement in cost ratios

Modern diode and fiber lasers have lifetimes of more than 20 000 operating hours and are guaranteed to work without any problems even in industrial conditions. The costs compared to other methods have also improved simultaneously. This cost efficiency is emphatically highlighted by the use of this method in the permanently cost-driven automotive subcontracting sector – where the transmission laser welding of thermoplastics cuts a very good figure in the total cost calculations. This has moved it from a niche application to the technique of choice.

The laser welding of plastics reduces the amount of consumables and boasts outstanding welding quality. Laser welding is a non-touch method which reduces the mechanical stress on a component to an absolute minimum. The only pressure applied to the product is the orthogonal joining pressure. And there are no vibrations which could damage the plastic housing or harm components on the inside of the product.

It was precisely this advantage which led to the breakthrough of laser welding, because this made it ideal for welding electronic housings of all kinds. These components cannot be joined together by ultrasonic welding because of the damage this could cause to electronic components. Screwing or gluing is expensive – which means that laser welding is the obvious choice.

And because laser welding is hygienic and boasts very high levels of process safety, it is also optimal for applications in the medical sector.

Broad areas of application

Laser welding is currently predominantly used in the automotive and medical sectors. The applications in the automotive market are frequently found amongst the subcontractors. The encapsulation of sensors and control units is a typical application.

Laser plastic welding is also gaining ground in the consumer market: precise welding seams in the visible parts of components are now found in many everyday goods.

Medical technology applications specify very high levels of hygiene in their production lines. And laser plastic welding is the method of choice for microfluidic applications: using lasers for the highly precise creation of the welding seams, and the absence of any particles produced during the laser welding process, is the only way of guaranteeing that sensitive microfluidic channels remain open and function perfectly.

Balloon dilation catheters for widening constricted coronary arteries have a zone which can be dilated during an operation. This zone is welded by a laser in a rotation process.

Better safe than sorry

Critical processes demand high quality – and this quality has to be permanently maintained and documented. A whole number of methods are already available during laser plastic welding to determine the perfect welding parameters. If the necessary interface is installed, laser plastic welding can be done with continuous tracking & tracing. Real-time recording during the welding process makes subsequent controls unnecessary, and in many cases enables the laser itself to automatically correct the identified fault.

Melt travel monitoring can be used during quasi-simultaneous welding. The criterion for successful welding in this case is defined by a specific amount of settling across the whole component.

In the pyrometer control method, a temperature curve is measured during the welding process: if this curve deviates from a defined upper and lower boundary, this may indicate faulty material or a foreign body which prevents proper welding. When necessary, the temperature signal can be used to directly control the laser output.

The scorch diagnosis method identifies thermal defects, whilst camera monitoring measures the width of the welding seam and visually inspects the homogeneity.

Reflection diagnosis

Reflection diagnosis is a completely new method that can be ordered as an optional accessory for welding systems from autumn 2010.

Reflection diagnosis takes advantage of the physical effect of the total reflection of light at boundaries. Such a boundary exists between two parts before they are joined. When light – including laser light – hits this boundary, a certain amount is reflected. The boundary changes when the zone is welded, reducing the amount of reflected light. Measuring this change in the amount of reflected light enables faulty seams to be detected.

This method can be used to check the quality of the welding seam in real-time. Depending on the product, the methods can be combined to enable the continuous tracking & tracing of specific components.

Patented laser staking

Laser staking combines riveting technology with laser plastic welding. It creates a form-fitted join between two components. Because the riveting tool does not come into contact with the plastified material, no plastic adheres to the tool, so this method can be used to join together components that cannot be welded directly – for instance, fixing printed circuit boards into plastic housings. The LPKF LQ-Spot system is completely inline-compatible.

Positive development

Laser plastic welding will continue to conquer new areas of application in future – by virtue of its clean-room compatibility, the integrated process controls, and the outstanding visual results. Laser plastic welding also makes economic sense. Completely new products are possible when combined with other methods – such as using laser structuring to apply circuit tracks to a sensor housing, and then safely sealing the housing using laser plastic welding.

Author

Frank Brunnecker, Vice President Business Unit LaserWelding

Representant

Solectro AB

Tenngatan 6 – 8

234 35 Lomma Sweden

Tel.: +46 (0) 40-536600

Fax: +44 (0) 40-536610

E-mail: solectro@solectro.se

Homepage: www.solectro.se

Ämnen

Kategorier

Regioner

Solectro AB grundades 1983 av Gerhard Tetzlaff.

Verksamheten omfattas av utveckling, produktion, försäljning och service av komponenter för automatisering, komplettlösningar, specialmaskiner, robotar, CNC-maskiner,PCB-prototying, laser, SMD samt dentalmaskiner.

Solectro AB är beläget i Lomma - ca. 10 minuter från Malmö och Lund.

Adress:

Tenngatan 6 - 8, 234 35 LOMMA

Tel. 040-536600

Fax 040-536610

E-mail: solectro@solectro.se

www.solectro.se