News -

Achieving circularity: Burckhardt Compression's revamp of Sherritt International's 60-year-old compressor

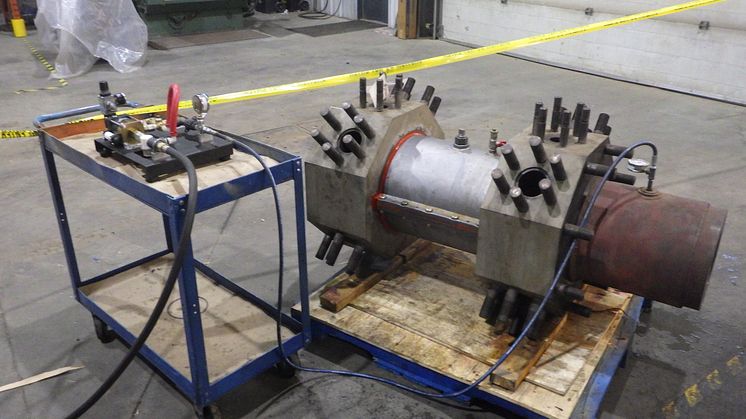

Burckhardt Compression Canada has successfully overhauled a 60-year-old compressor for Sherritt International Corporation, a leader in nickel and cobalt mining and refining. The aging compressor, suffering from severe wear and moisture damage, was no longer supported by its original manufacturer—posing a major operational risk.

Faced with an urgent need for a solution, Sherritt sought Burckhardt Compression's expertise in compressor technology. Through meticulous assessment and reverse engineering, BCCA completely rebuilt the compressor to precise specifications. This comprehensive overhaul included custom-engineered spare parts, such as specialized cylinder liners, robust/proprietary Persisto® materials, and updated piston ring designs. Each component was carefully designed to enhance durability, efficiency, and overall performance.

These tailored improvements resolved chronic reliability issues, increasing/boosting the compressor's availability from 62% to an impressive 88%. It now operates reliably, running three times longer than before and significantly reducing unplanned downtime. This achievement aligns with both companies' sustainability goals by minimizing resource consumption and waste.

“The machine is now in operation, and this would not have been possible without your shop’s support. Working together, we were able to develop specifications for all the parts that needed to be refurbished. Your team met our deadline and there were no issues with any of the work completed. Your experts did an excellent job of keeping track of the project and providing weekly updates. The outstanding presentation was what sold us on Burckhardt’s expertise and qualification to complete this work. No matter what the problem is, they can always come up with a solution. The cleanliness and organization of the shop is the best I have seen.”

John Young, Mechanical Engineer, Sherritt International Corporation

This project is part of Burckhardt Compression’s broader commitment to industrial circularity. As part of its Mid-Range Plan, the company aims to complete similar revamps by 2027, extending the lifespan of critical infrastructure worldwide.

For more detailed information on this success story, including technical specifics and project execution, please visit Burckhardt Compression’s website https://www.burckhardtcompression.com/about/news-stories-and-whitepapers/article/60-year-old-compressor-revitalized-for-continuous-reliable-operation/

Further information:

Claudia Proeger, Global Marketing Manager

Phone +41 52 261 50 70; Claudia.proeger@burckhardtcompression.com