Press release -

Optimizing compressor availability with the new module ‘Predictive Intelligence’ for PROGNOST®-NT

Digital solutions are proven to be key to extend ‘Mean Time Between Failures’ across the industry. As the first mover in the compression market, Burckhardt Compression is now able to support operators of reciprocating compressors by reliably predicting the remaining useful lifetime of key components of their assets. Artificial Intelligence (AI) based predictive algorithms and real-time data are used to maximize equipment availability and reduce Total Cost of Ownership.

Supported by 180 years of experience in compressor manufacturing, Burckhardt Compression’s latest digital solution enhances equipment availability by predicting the best time for routine maintenance. By combining real-time data with historic information from similar machines and analyzing it using cutting-edge predictive algorithms, it is possible to establish the Projected Availability Span and the Remaining Useful Lifetime (number of days) of key components in the compressor.

Focused maintenance

Central to the dependable performance of a compressor is the reliability of the valves and packings, as they are typically responsible for the majority of unplanned downtime. Assessing the expected lifetime of these components and planning accordingly can make a significant improvement in availability.

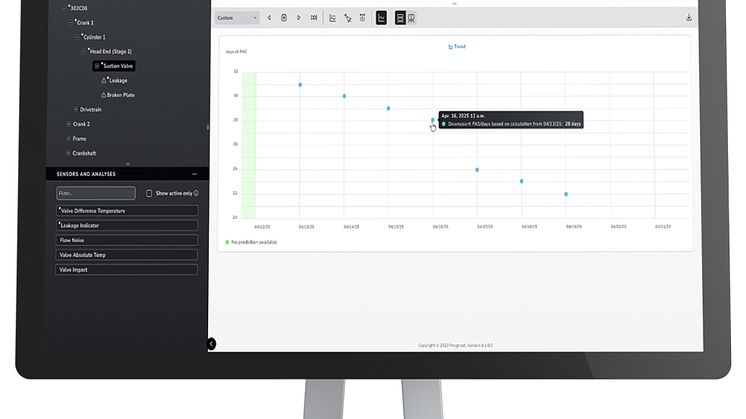

Designed to work with the version 21 of our monitoring and diagnostic system PROGNOST®-NT, the ‘Predictive Intelligence’ software delivers an easy-to-understand report with trends that indicate the best time for maintenance without risking unexpected downtime. Data from various signal analyses is uploaded to the secure Azure cloud environment, where it is continuously analyzed to provide actionable information to the operator.

Expert insights and advice

Predictive Intelligence enables operators to coordinate compressor maintenance with other scheduled maintenance periods, and allocate the necessary parts and resources, thereby minimizing unplanned disruption. In addition, it ensures that the service life of each component is maximized without compromising the reliability of the compressor.

As part of Burckhardt Compression’s portfolio of digital solutions, Predictive Intelligence uses the latest AI technology for the benefit of all reciprocating compressor operators. Combining decades of design expertise and application knowledge with cutting-edge software, Predictive Intelligence enables optimized maintenance planning for extended availability, an increased lifespan and minimized operating costs.

The new software module is now available to selected customers for specific applications.

For further Information please contact:

Daniela Daron, Global Marketing Manager, Services Division

Tel. +41 52 261 57 09, daniela.daron@burckhardtcompression.com

Related links

Categories

About Burckhardt Compression

Burckhardt Compression creates leading compression solutions for a sustainable energy future and the long-term success of its customers. Together with its brands Burckhardt Compression, PROGNOST, SAMR Métal Rouge and Shenyang Yuanda Compressor, the Group is the only global manufacturer that covers a full range of reciprocating compressor technologies and services. Its customized and modularized compressor systems are used in the Chemical/Petrochemical, Gas Transport & Storage, Hydrogen Mobility & Energy and Industrial Gas sectors as well as for applications in Refinery and Gas Gathering & Processing. Since 1844, its passionate, customer-oriented and solution-driven workforce has set the benchmark in the gas compression industry.

SIX Swiss Exchange: BCHN

Further information at www.burckhardtcompression.com, LinkedIn

Note to Editors:

This press release is issued in accordance with Associated Press (AP) style guidelines. Please use proper attribution when referencing this press release.