Press release -

Plastics can also be a circular economy

Plastic products end up in the rubbish after a short period of use. A large part of it is incinerated, which means that valuable material is lost. The circular economy has now also arrived in the plastics industry. Machines for plastics processing can be purchased second-hand. This also contributes to sustainability.

If one wants to maintain or improve people's standard of living and at the same time protect the environment, economic growth and demand for raw materials must be decoupled from each other. The circular economy can make this possible. It is thus an essential tool for combating climate change. Moreover, the circular economy creates independence from supply chains. And in the end, it even saves money.

Which material is the right one? There are two main aspects that it would need to fulfil in a circular economy. Firstly, it would have to be versatile as a material (not as an incineration material), and secondly, cascading use would need to be possible. This means that a raw material can be used several times in succession to manufacture products. At the end of the cascade is the final thermal utilisation of the residual and waste materials.

Plastics in Europe – figures, data, facts

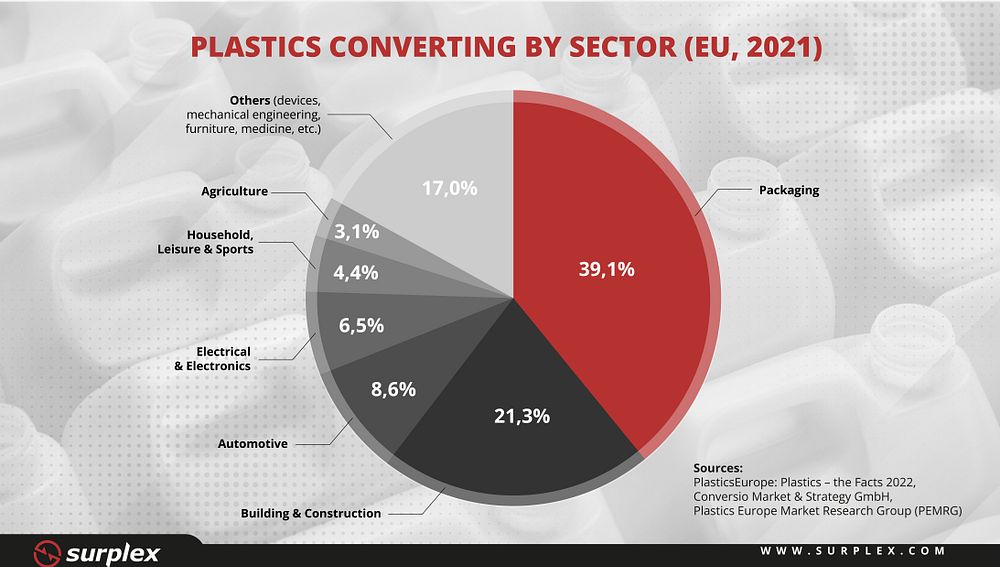

In 2021, 57.2 million tonnes of plastics were produced in the EU – and the trend is rising. This corresponds to about one sixth of global plastic production. The largest share of the plastic produced is used in the packaging industry (approx. 40%), followed by the construction industry (approx. 20%) and the automotive industry (approx. 10%).

As plastic production increases, so does the amount of waste generated. In 2020, more than 29 million tonnes of plastic waste were produced across Europe. Only one third of this could be recycled. One quarter of the waste was deposited, while the remaining 40% was used in energy recovery. The amount of plastic deposited is steadily decreasing, while the amount recovered (recycling and incineration) is increasing. As part of its Green Deal, the EU is pushing for 55% of plastic packaging waste to be recycled by 2030.

One might think that bio-based plastics are the solution to all problems. However, as of 2019, they only account for a share of a good two percent. Fossil-based thermoplastics such as PP, PE, PVC, PET and PS dominate plastics production with a share of just about 90%.

Recycling as the basis for the plastic’s circular economy

There are two types of plastics cycles: pre-consumer and post-consumer recycling. The waste generated during the production and processing of plastics is collected, reprocessed if necessary and used again in production together with the new plastic. This is called pre-consumer recycling. The advantages here are the short distances, as the plastic is often reprocessed internally, and that the production waste is clean and its chemical composition is known to the producer.

In post-consumer recycling, the waste from end consumers is reused. In many countries, plastic waste is collected separately: e.g. the deposit return of bottles or the yellow bag in Germany and Austria. The collected material is sorted, washed and processed into granulate – also known as post-consumer recyclate. Products can then be made again from this recyclate. For example, old fishing nets are turned into watering cans for children. PET bottles can be recycled to produce new bottles. Compared to production from new PET, this saves up to one tenth of CO2 emissions.

The circular economy is not yet completely round

Recycling is still a complex and expensive process that requires energy and emits greenhouse gases. In addition, recycled material is often of lower quality than virgin plastic. The use of recyclate in production may fail to meet quality and hygiene requirements. However, wherever possible, recycled material should be used.

In addition, recycling starts long before production. When developing their packaging, design teams must consider mind how a plastic product can later be successfully recycled. Only if consumers can easily separate the individual components of the packaging, can they be further reused in a circular economy.

Sustainable used machinery

The trade in used machinery is a step in the cascade use of machinery and thus a contribution to the circular economy in machinery and plant engineering sector. Every used machine saves considerable amounts of greenhouse gases and raw materials compared to new production. With around 55,000 machines and operating equipment that are auctioned annually at the industrial auction house Surplex, the CO2 reduction amounts to around 1,300 t every year. Plastics processors will find what they are looking for on Surplex.com, where regular auctions of machines and inventory for plastic processing take place, offering companies the ideal opportunity to make their production even more sustainable.

_______________

About Surplex

Surplex is one of Europe’s leading industrial auction houses and trades worldwide with used machinery and equipment. The 16-language auction platform Surplex.comrecords approximately 50 million-page views annually. More than 55,000 industrial goods are sold each year at more than 800 online auctions. The company is based in Düsseldorf (Germany) and has offices in 15 European countries. Over 220 employees from 20 different nations generate an annual turnover of more than EUR 100 million.