Pressemeddelelse -

Agritechnica Innovation Awards: One Gold and four Silver medals for groundbreaking CLAAS innovations

With a Gold Agritechnica Innovation Award and four Silver Medals, CLAAS once again emphasises its strength in innovation as the largest family-owned agricultural machinery company. The groundbreaking new products in the fields of balers, maize harvesters, and tractors, along with a collaboration in mechanical chopping, further enhance performance and efficiency while reducing operator workload.

Agritechnica, the world’s premier agricultural machinery trade fair, offers manufacturers an international stage for new innovations and developments once again this year. The DLG’s New Product Committee highlights groundbreaking advancements with the Agritechnica Innovation Awards in gold and silver, along with the Agrifuture Concept Winner Awards. CLAAS, securing an Innovation Award in gold and four silver awards – one in collaboration with Einböck – reaffirms its innovative strength and status as one of the leading names in agricultural technology.

Gold for the next-generation of square baler capable of processing 70 tonnes per hour

CLAAS receives a Gold Agritechnica Innovation Award for the next performance class of square balers, featuring a completely new, revolutionary overall concept that will position CLAAS’s baling programme above the QUADRANT range in the future. The machine, with a bale size of 120x90 cm, combines high throughput with consistently high bale densities. In practice, this new concept achieves up to 70 t/h throughput when baling straw and maintains constant bale densities of 210 kg/m³, reaching even up to 235 kg/m³ at peak performance.

Among other features, these functions are enabled by the main gearbox integrated into the frame with a straight-line power flow. The innovative drive operates with two longitudinal flywheels, each at 1,650 rpm, which store considerable energy to ensure uniform compaction. Power transfer is handled solely through efficient, low-loss, and wear-resistant enclosed gearboxes, in addition to two power belts. Sensors in the rotor or rake gear continuously monitor gear loads and automatically adjust assistance systems, such as AI-assisted press density control and bale length regulation.

Additional innovations feature a new mechanically driven single-row packer for the pre-chamber and a newly designed double-loop knotter. The latter generates two loop knots per binding operation, merging the benefits of McCormick and Deering knotters while avoiding their individual drawbacks. It ensures strong knots with minimal yarn tension, without leaving yarn remnants in the field.

Two Silver medals for JAGUAR innovations

The global market for forage harvesters demands machines with ever higher throughput, greater comfort, and improved efficiency. With the new JAGUAR 1000 series, awarded a Silver Agritechnica Innovation Award for its overall concept by the DLG Innovation Commission, CLAAS has created a new platform specifically tailored to the requirements of this high-performance segment. Building on the DNA of the well-known 900 series, a completely new machine concept has been realized, featuring harmonized components, the widest chopping drum on the market (910 mm), and the powerful MULTI CROP CRACKER XL with 310 mm roller diameter. The result is at least a 20 percent increase in throughput compared to the JAGUAR 990, achieving up to 500 t/h of fresh mass with engine outputs of up to 1,110 hp.

The innovative character of the new series, consisting of four models – JAGUAR 1080, 1090, 1100, and 1200 – is also evident in numerous details that improve harvesting efficiency, enhance operator comfort, and further optimize chopping quality. The driver benefits from an extremely quiet cab, automatic functions such as CEMOS AUTO PERFORMANCE, and the new optional joystick steering. Further highlights include new ORBIS and PICK UP front attachments with independently controlled drives, a factory-installed tire pressure control system for both axles, all-wheel drive, and differential locks for both axles. In addition, the new ISOBUS-based NUTRIMETER NIR sensor enables live yield mapping on the CEMIS 1200 terminal for the first time. Fleet and machine management, as well as documentation, are handled via the cloud-based CLAAS connect system.

Another Silver Agritechnica Innovation Award goes to CEMOS AUTO CHOPPING, a further development of CLAAS’s AI-supported and cloud-based chopping quality analysis. The CSPS value (Corn Silage Processing Score) is a central indicator of kernel processing quality and thus the quality of corn silage. For many years, determining this value was only possible in a laboratory. With CEMOS AUTO CHOPPING, CLAAS is now introducing an assistance system for the JAGUAR 900 forage harvester that determines kernel processing quality in real time and automatically adjusts harvester settings in case of deviations.

The core of the innovation is a camera with a CMOS image sensor installed in the discharge chute, which uses Artificial Intelligence (AI) to analyze the forage structure and determine kernel processing. If the measured value deviates from the target, the system automatically adjusts the cracker gap, driving speed, and engine output. The collected data can also be transferred to the cloud-based farm management system CLAAS connect, documented there, and used for quality assurance or billing purposes.

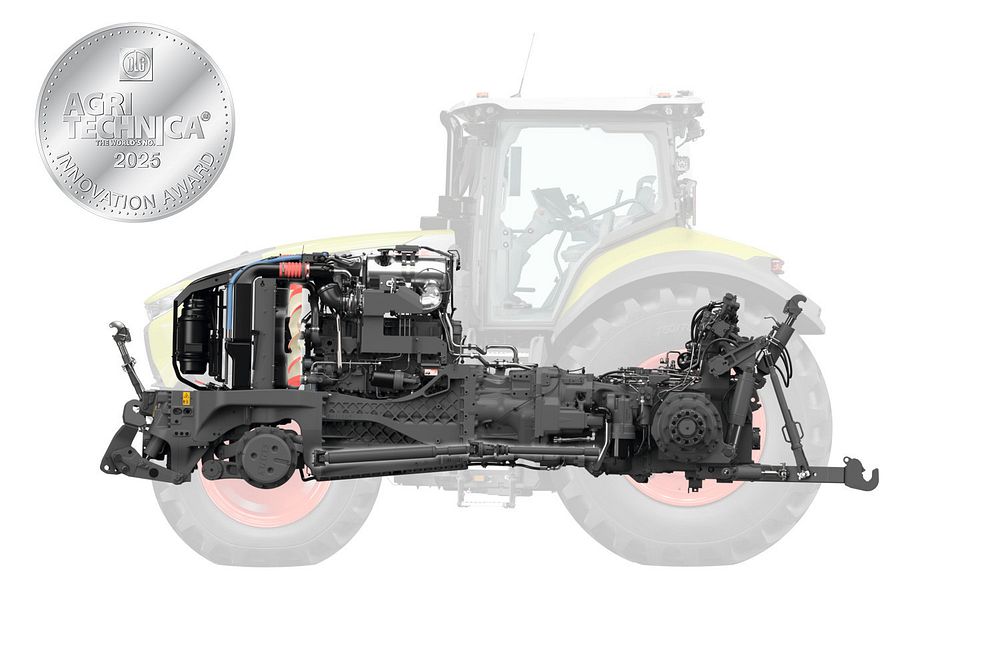

Silver for predictive, fully adaptive driveline management for continuously variable tractor transmissions

For decades, CLAAS has significantly influenced the development of both driver assistance systems and tractor innovations, repeatedly receiving international recognition. The fully adaptive driveline management system, awarded a Silver Agritechnica Innovation Award this year, continuously and proactively optimizes engine speed and transmission ratio based on a self-learning algorithm and efficiency maps for the engine, continuously variable transmission, hydraulics, and auxiliary systems.

The central innovation, “Auto Load Anticipation,” detects load changes – for example, when lowering an implement into the soil – in advance and proactively increases engine speed before the load change occurs. This ensures stable driving behavior during dynamic transitions and prevents engine speed drops. Additional functions adjust engine speed and transmission ratio depending on load, travel speed, and hydraulic demand, delivering the required power under all operating conditions with minimal fuel consumption. The result is highly dynamic yet fuel-efficient driving behavior, without requiring manual inputs from the driver.

Silver for Einböck and CLAAS: SMART-HILL slope compensation with CULTI CAM

Another Silver medal is awarded by the DLG Innovation Commission to a cooperative project between Einböck and CLAAS for fully automatic slope compensation in hoeing equipment. Control of the SMART-HILL system is handled by the high-resolution CLAAS CULTI CAM stereo camera, which analyzes color information and 3D surface models to precisely detect slope inclination. The integrated job computer processes this data in real time and controls the additional rotating axis of the shift frame via a proportional valve. This ensures that the hoe always remains at a 90° angle to the row, even in slope situations or during sharp steering manoeuvers.

This highly precise compensation takes camera-based row detection on slopes to a new level, enabling unprecedented accuracy in mechanical hoeing. For the first time, finger hoes can now be used reliably on slopes. In combination with existing control systems, SMART-HILL provides maximum precision even at higher working speeds and under challenging conditions.

Emner

Kategorier

About CLAAS

Founded in 1913, the family-owned company CLAAS (www.claas.com) is one of the world’s leading manufacturers of agricultural machinery. Headquartered in Harsewinkel, Westphalia, CLAAS is the world market leader in forage harvesters. In another core segment, combine harvesters, CLAAS holds the European market leadership. CLAAS also ranks among the global leaders in agricultural engineering with tractors, balers, and forage harvesting machines. The product range also includes the latest agricultural information technology. CLAAS employs 12,000 people worldwide and achieved a turnover of 5 billion euros in the 2024 fiscal year.