Pressemeddelelse -

CLAAS further develops TRION series and adds new TRION 760 top model

Four years after its market launch, the TRION series from CLAAS continues to set standards in the mid-sized combine harvester segment. The new models impress with their greater harvesting performance: engine outputs of up to 507 hp further increase throughput, while the larger grain tank volume of 13,500 litres increases productive time by reducing overloading and offers reserves for long fields. As with the LEXION, comfort-enhancing innovations in the cab and in the area of maintenance have been introduced throughout the TRION series.

With the three TRION 500, TRION 600 and TRION 700 series, CLAAS has been offering the most comprehensive and widest range of combine harvesters in the medium power class on the market since summer 2021, meeting the diverse requirements of international customers in a unique way. Farmers and contractors are not only able to choose between 5 straw walkers and 6 straw walkers as well as the powerful APS HYBRID machines – but also have the option of wheel, TERRA TRAC and MONTANA variants. With its wide range of models, simple and proven reliable technology, unbeatable ease of maintenance and intuitive, immediately understandable operation, the new TRION appeals to an extremely broad international customer segment, true to the motto - "Simply fits".

New top model TRION 760; more power with new engine and DYNAMIC COOLING for the TRION 750.

From the 2026 model year, the TRION 700 series will be available as a wheel, TERRA TRAC or MONTANA* variant with the APS HYBRID system, which has been tried and tested a thousand times over for many years:

Model | Separation | Engine | Max. grain tank |

TRION 760 / 760 TT | APS TWIN HYBRID; |

MAN D26; 507 HP | 13.500 l |

TRION 750 / 750 TT / 750 MONTANA* | APS TWIN HYBRID; |

MAN D26; 466 HP |

12.000 l (MONTANA: 11,000 litres) |

TRION 740 / 740 TT / 740 MONTANA* | APS SINGLE HYBRID; |

Cummins L9; 435 HP |

12.000 l (MONTANA: 11,000 litres) |

TRION 730 / 730 TT / 730 MONTANA* | APS SINGLE HYBRID; |

Cummins L9; 408 HP |

12.000 l (MONTANA: 11,000 litres) |

TRION 720 / 720 TT / 720 MONTANA* | APS SINGLE HYBRID; |

Cummins L9; 367 HP | 12.000 / 10.500 l |

* with hydraulic chassis slope compensation: compensation of cross-slopes of up to 18 per cent to ensure maximum throughput capacity even on steep slopes

The TRION 760 and TRION 750 use an APS TWIN HYBRID threshing unit with a 1,420 mm feed channel width, 600 mm threshing drum and two axial rotors with a diameter of 445 mm and a length of 4,200 mm for high-performance separation. For the three other TRION 700 models, CLAAS continues to rely on the APS SINGLE HYBRID threshing unit with a 570 mm axial rotor for residual grain separation.

The new top model in the TRION 760 series is powered by a MAN D26 engine with a displacement of 12.4 litres and a rated output of 507 hp. Thanks to its large grain tank with a capacity of 13,500 litres and the more powerful front-attachment drive, the TRION 760 achieves a significant increase in productivity and efficiency, especially on high-yielding sites and when harvesting grain maize. Thanks to DYNAMIC POWER, the engine power always adapts to the respective conditions of use, ensuring efficient work with fuel savings of up to 10 per cent. On the road, the two new TRION top models travel at a top speed of 30 km/h at a reduced engine speed of 1,600 rpm, so that they are always on the move quickly, but with maximum efficiency and cost savings, even over longer distances between work sites.

To take account of the increased engine power, the powerful cooling in the TRION 760 and TRION 750 is provided by the horizontal cooling package familiar from the LEXION. Thanks to DYNAMIC COOLING - standard on board the TRION 760 and TRION 750 for the first time - the variable fan adapts its output to the working conditions, saving up to 15 kW of power. This power saving is then available for the ground drive or other units - or ensures a further reduction in absolute fuel consumption of up to 10 per cent.

Cab with Apple CarPlay and Android Auto as well as new interior lighting.

From the 2026 model year, an Apple CarPlay and Android Auto radio with a 6.75 inch touch display, DAB+ incl. optional subwoofer and Bluetooth will be available in the cab for all three TRION model series. A compressed air connection with a blow gun is also available in the cab for quick and easy cleaning of controls and the cab floor. Thanks to new interior lighting, working in the evening and at night is even more pleasant and safer. New, large storage compartments in the left-hand B pillar also offer additional storage options, providing the operator with even more comfort at the highest level.

In addition to the innovations in the cab, the new LED work lighting also sets standards in the mid-range performance segment - with up to 75 per cent higher ambient illumination and perfect alignment, it turns night into day and ensures greater safety both in the field and on the road. As a visual highlight, LED all-round and rear lamps are now also available for all TRION series. All innovations in the cab and cab environment will be available in various equipment packages from the 2026 model year. Different levels of equipment will be available to meet different customer requirements, focussing on operator comfort as well as light and environmental visibility. In addition, a compressed air connection is available in the cab access area for cleaning the connections on the feed channel.

CEMOS driver assistance and machine optimisation combined.

With its combine harvesters, CLAAS has been a world leader in grain harvesting for decades. With the revolutionary CEMOS AUTOMATIC, LEXION and TRION have been setting the standard in the field of self-learning combine automation and optimisation to achieve the highest machine efficiency and maximum productivity for years. CLAAS offers the CEMOS AUTOMATIC combine harvester optimisation system in three expansion stages to meet all customer requirements for automation and driver relief:

- CEMOS AUTO for up to 10 percent increased throughput capacity, significant learning effects and noticeably more driving comfort thanks to dialogue-based optimisation, automatic regulation of the forward speed and automatic crop flow monitoring. The menu-guided loss sensor calibration is unique on the market.

- CEMOS AUTO Plus for up to 20 percent performance optimisation and automatic optimisation of residual grain separation, cleaning and digital sweep control in CEBIS.

- CEMOS AUTO Professional for more than 20 percent more output, including automatic setting of the threshing unit and camera-based, permanent optical monitoring, analysis and optimisation for maximum machine throughput with consistently top grain quality and minimum trash.

Fully networked with CLAAS connect.

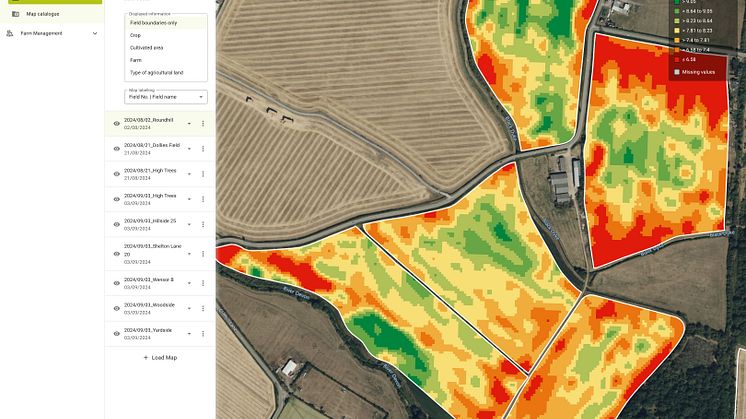

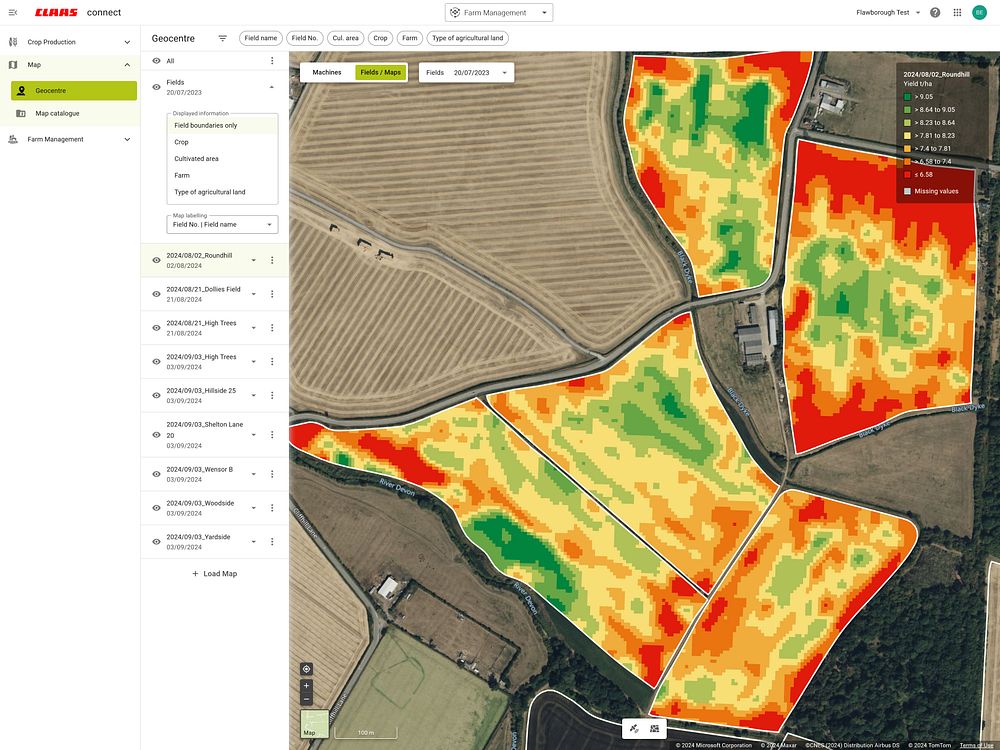

With CLAAS connect, CLAAS is setting new standards in connectivity for both the LEXION and the TRION: From machine configuration, purchase processing, access to product documentation and the lubricant guide, maintenance planning and documentation to cross-manufacturer fleet management via DataConnect, automatically generated and highly accurate yield maps and other smart farming applications - CLAAS connect also enables comprehensive networking for the TRION with automatic documentation and access from the office or from a mobile device while on the move:

- Precise track guidance: CEMIS 1200 as an intuitive steering terminal; whereby the optimum reference lines can be planned in advance in CLAAS connect based on the field boundaries and then used and shared.

- Clear order management: Orders are easily and conveniently created in CLAAS connect and called up on the CEMIS 1200. Orders can be documented and managed directly on the machine.

- Automatic documentation with CLAAS connect: Automatic documentation of field work is also possible without creating jobs for a complete database. Interpolated yield maps of outstanding quality can be created automatically from the machine's yield points.

- Real-time information: Machine position and status as well as current machine data, settings and performance can be viewed from anywhere. This enables convenient navigation to the machine's operating location. In addition, CLAAS connect informs the user how long the work in the field is likely to take - regardless of how many machines are currently working in the field. This allows harvesting operations and harvesting logistics to be optimally planned and coordinated.

- Analyse and optimise: Detailed analyses enable optimisations and comparisons between different machines. Efficiency, performance and yield data can be analysed as a whole.

- Precise planning: The remaining working time per field can be estimated based on current performance data. CLAAS connect also provides detailed field overviews and satellite data for monitoring vegetation and pre-planning harvesting operations.

The most important machine-related CLAAS connect functions are also summarised as packages for the customer and available for TRION and LEXION :

- Connect Package includes the 5-year Machine connect licence for displaying machine and service information in CLAAS connect and the QUANTIMETER for yield recording.

- Connect Package Professional extends the Connect package with the GPS PILOT CEMIS 1200 including activation for RTK use, TC-GEO functionality and order management for even more accurate site-specific yield mapping.

- The full range of functions in CLAAS connect is available with the upgradeable farm-based licences. These are valid per farm and not per machine, and therefore enable a wide range of applications across several machines. All functions relating to automatic documentation and Precision Farming are covered.

The most important new features of the TRION at a glance:

- New top-of-the-range TRION 760 model is powered by a MAN D26 engine with a rated output of 507 hp and has a 13,500 litre grain tank.

- The TRION 750, now with a rated output of 466 hp, is also equipped with the MAN D26 engine.

- DYNAMIC POWER and DYNAMIC COOLING with horizontal radiator system, variable fan and intelligent power management for fuel savings of up to 10 per cent on the TRION 760 and 750.

- Cab update with AppleCar Play and Android Auto radio with DAB+ incl. optional subwoofer and Bluetooth as well as additional storage compartments, compressed air connection in the cab and new interior cab lighting for all TRION series.

- New LED work lighting with up to 75 per cent higher illumination for greater safety in the field and on the road, as well as new LED all-round and rear lamps with a modern look for all TRION model series from the 2026 model year.

- Summary of CEMOS driver assistance and machine optimisation in three practical, customised packages: Up to 20 per cent more performance with significant driver relief and consistently high threshing quality thanks to features such as the GRAIN QUALITY CAM.

CLAAS connect machine and data management optionally summarised as Connect package or Connect Professional package.

Emner

Kategorier

About CLAAS

Founded in 1913, the family-owned company CLAAS (www.claas.com) is one of the world's leading manufacturers of agricultural machinery. Headquartered in Harsewinkel, Westphalia, the company is the world market leader in forage harvesters. CLAAS has also been the European market leader in another core segment, combine harvesters, for decades. CLAAS is also a world leader in agricultural technology with tractors, agricultural balers and grassland harvesting machinery. The product range also includes state-of-the-art agricultural information technology. CLAAS employs 12,000 people worldwide and achieved a turnover of 5 billion euros in the 2024 financial year.