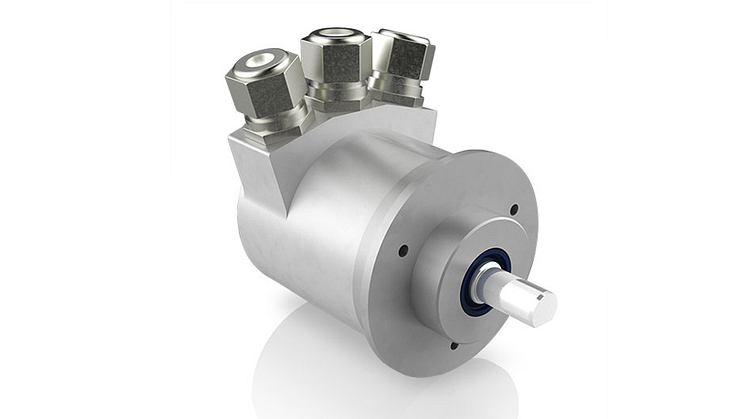

Products and solutions from Leine Linde

We want our customers to succeed. Our innovative products and solutions can always be tailored for your specific requirement. With our reliable encoders and software, you’ll get accurate feedback of speed, position or strain.

We are not just any other encoder supplier. Contact us to find out more!