Meet Leine Linde at the TOC exhibition!

Come and meet our team and learn about our products and solutions for marine environments with integrated safety and built-in condition monitoring.

You’ll find us in B76.

Come and meet our team and learn about our products and solutions for marine environments with integrated safety and built-in condition monitoring.

You’ll find us in B76.

Som en del av Leine Lindes strategiska hållbarhetsarbete, har en 870 kvm stor solcellsanläggning installerats på huvudkontoret i Strängnäs. Anläggningen kommer ha en årlig produktion på ca 147 000 kWh, vilken motsvarar årsförbrukningen för 7–8 villor.

– För oss på Leine Linde är det ett självklart val att satsa på solenergi då det ligger helt i linje med vårt hållbarhetsarbete för att mins

Leine Lindes produkter hör till premiumsegmentet och är särskilt konkurrenskraftiga där det krävs hög tillförlitlighet och noggrannhet i utmanande industriella miljöer.

ADS Uptime™ is an extremely useful condition monitoring system for encoders. With local wireless service check-up or system integration with ADS Link, you have maximum flexibility to access data and diagnostics. With ADS Uptime, you can access live data and secure production uptime by making application health monitoring part of your proactive maintenance routine. Knowing things before they happen

We start 2023 by looking back at highlights from last year.

The year 2022 was an eventful year for us, filled with a lot of exciting events and meetings with customers and business partners.

Now we throw ourselves into 2023 with the good hope that the year will be at least as eventful.

Thank you for good partnerships and for the great moments together during 2022!

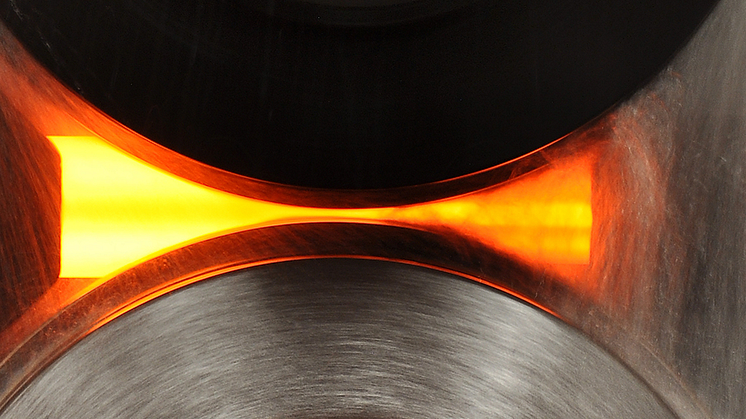

Do you strive for increased productivity, lowered material consumption and quality improvement? Leine Lindes gap control solutions are easily integrated in steel mills and other metal processing industries. We offer extremely reliable and accurate gap control, to assure both the quality of the end product and the lowest possible material consumption.

Are you an OEM manufacturer within t

On January the 27 our product management team presented last years product highlights on a digital broadcast from our flagship showroom at our HQ in Strängnäs, Sweden.

Topics on the broadcast:

Encoders with added features:

Encoders for functional safety

Condition monitoring solutions for increased uptime

EX certified encoders

Encoders for large (and very large) drives.

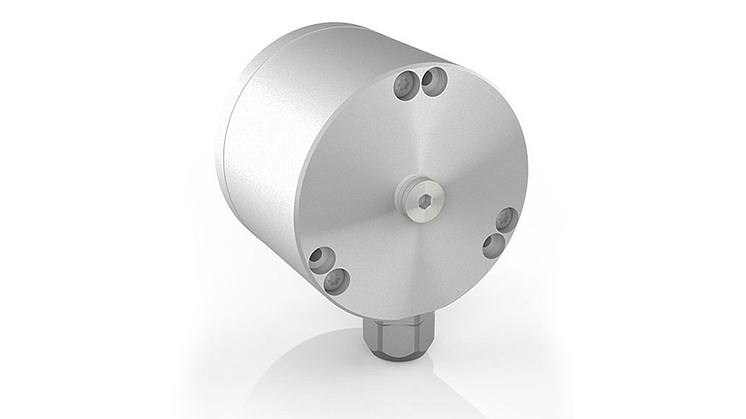

Small, robust and versatile. Our new line of inductive encoders, the M500 series, is designed to meet the challenges of today, as well as the requirements of tomorrow.

Each of these incremental and absolute inductive encoders comes with its own unique set of benefits. What they have in common is an immunity to contamination and electrical or magnetic disturbances. Even the worst enviro

One of Leine Linde’s Danish customers is a manufacturer of machinery for the food industry. In one particular case they were building a machine for drying and roasting nuts, to be shipped to an end customer in the US.

A lot of dust is created as nuts are processed, creating a challenging environment for encoders. To adapt a RHI 593 encoder to the dusty environment, our engineers added an inle

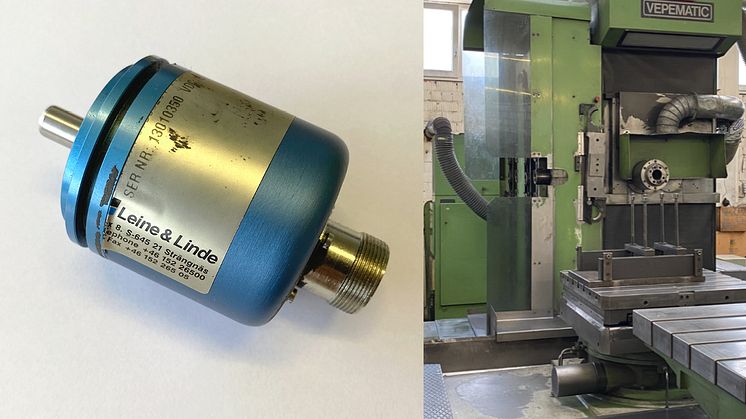

This encoder was installed at German industrial saw manufacturer FORTE GmbH the same year as Microsoft first released Windows 3.1. That same year, Bill Clinton was elected president of the United States, IBM sold the first ThinkPad and Irish band U2 released the single One, while Boyz II Men managed to top the Billboard list with their hit End of the Road. That was 29 years ago, in 1992.

This e

The ISA 698 encoder with GORE-TEX valve was originally developed for rock drilling rigs in the mining industry. The new GORE-TEX valve prevents moisture from accumulating inside the encoder. Instead, it enables a one-way release of moisture to keep the inside of the encoder dry, for optimal operation.

Encoders with GORE-TEX valves are suitable for use in humid environments where the te

Some of the liquids that are processed in the food industry are really acidic. Cleaning agents and other aggressive substances are frequently used in and around the machines and encoders used must withstand occasional splashes and exposure to such fluids. For one of these machine manufacturers, Leine Linde developed a splash-proof and corrosion resistant absolute encoder used for positioning a