Press release -

Lufthansa Cargo Newsticker, September 25, 2025

- Successful pilot project for the semiconductor industry

- Digital Pharma Station Map now online

- New technologies for more efficiency: Lufthansa Cargo is testing new scanning technologies in its warehouses

- Lufthansa Cargo to Attend Three International Trade Fairs

Successful pilot project for the semiconductor industry

Lufthansa Cargo has teamed up with DSV to implement a pilot project for the transport of highly sensitive semiconductor production machinery from Japan to Germany. “"We wanted to demonstrate that we have the necessary product and service components at hand to address the unique requirements of the semiconductor industry,” explains Brinthavani Ehanantharajah-Przybilla, Senior Manager Industry Development – Semiconductors.

In June 2025, representatives from Tokyo and Frankfurt met with DSV for a workshop. The aim was to clarify the specific requirements in detail and to improve the import process at the hub FRA. Semiconductor production machines are extremely sensitive to vibrations, tilting, and temperature fluctuations. Therefore, processes were coordinated together with shock and tilt sensors, temperature monitoring, checklists, and clear handling rules.

At the end of August, two test shipments were made from Narita via Frankfurt to Dresden – both successful, with a third following in September. “These test runs have shown that we can meet the high requirements of the semiconductor industry,” says Kazuhiro Enya, Sales Manager Eastern Japan.

The project was a joint effort from the outset. In addition to the sales team in Japan and the industry development team in Frankfurt, the handling team contributed valuable practical knowledge. The time:matters Courier Terminal contributed its experience in special handling. Oliver Blum, Head of Airmail, Courier & Perishable Handling Frankfurt: "The key to success was that each side was able to contribute its perspective, from sales to handling. This allowed us to learn from each other and create a solution together."

With the successful test shipments, the foundation has been laid for the safe handling of further transports of this kind in the future. Lufthansa Cargo is also working on incorporating the specific handling requirements into the booking system.

Digital Pharma Station Map now online

Lufthansa Cargo has launched an interactive map of its global Pharma Stations on its website. This tool provides greater transparency and convenience for the "Passive Temp Support" and "Active Temp Control" products. With over 200 stations worldwide, Lufthansa Cargo operates one of the largest networks for temperature-sensitive transport. More than 30 stations are CEIV- or GDP-certified, and there are over 125 temperature-controlled facilities (2°C-8 °C and 15°C-25°C), as well as CEIV-certified pharma transport processes. The Pharma Station Map can be found on the linked product pages under the 'Infrastructure' tab.

New technologies for more efficiency: Lufthansa Cargo is testing new scanning technologies in its warehouses

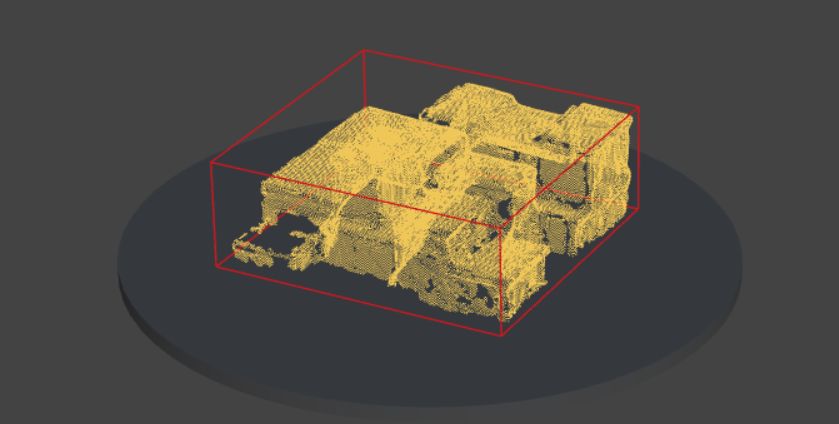

Lufthansa Cargo continues to actively drive forward the digitalisation of the air freight industry, constantly testing new technologies to increase operational efficiency. Most recently, artificial intelligence has been used increasingly during the booking process. To handle freight more efficiently in the warehouse and load aircraft more profitably, the cargo airline is currently trialling new measurement methods using computer vision in Frankfurt and Los Angeles.

Two different companies are working with Lufthansa Cargo at the Frankfurt Cargo Centre and in Los Angeles to test new cargo measurement technologies in daily operations. Shipments are scanned on the conveyor belt or forklift truck during ongoing operations, eliminating the need for an additional process step in the storage or loading process. The freight's actual dimensions are measured automatically and provided in real time, which will prevent discrepancies between declared and recorded dimensions in the future. This data can be used to optimise the entire transport chain, enabling aircraft to be utilised more efficiently, storage space to be evaluated more effectively, and onward transport routes to be planned more accurately.

Until now, this step has been carried out using laser scanners and manual checks. However, newer technologies can perform this task much more efficiently and accurately. Once the test phase is complete, Lufthansa Cargo will decide how these technologies can be used long term, and whether they can be used at other locations.

Lufthansa Cargo to Attend Three International Trade Fairs

Lufthansa Cargo will showcase its expertise this autumn at three major industry events around the globe. With a diverse portfolio of innovative solutions for global air freight, the company once again underscores its leading role in the logistics sector.

-

LogiPharma, Boston – September 29 to October 1, 2025

Focus on secure and efficient pharmaceutical logistics for temperature-sensitive shipments. -

Logistech, Izmir – October 8 to 10, 2025

Exchange on pioneering supply-chain concepts in international freight. -

MRO Europe, London – October 14 to 16, 2025

Europe’s leading trade fair for the commercial aviation aftermarket, combining a high-level conference with an international exhibition.

Visitors are cordially invited to meet the Lufthansa Cargo team on site to learn more about the company’s innovative services, digital solutions, and sustainable transport offerings.

Topics

Lufthansa Cargo

Lufthansa Cargo is one of the world's leading cargo airlines and part of the Lufthansa Group, Europe's largest airline group. Through its five cargo hubs in Frankfurt, Munich, Brussels, Vienna and Rome, the airfreight specialist transports an average of 2,500 tons of freight per day. This is based on a strong and reliable airport-to-airport network that covers some 350 destinations in more than 100 countries. Lufthansa Cargo markets the cargo capacities of the passenger aircraft of Lufthansa Airlines, Austrian Airlines, Brussels Airlines, Discover Airlines, ITA Airways and SunExpress, as well as its own freighter fleet of 18 Boeing 777F and four Airbus A321F. In addition, some 300 trucks operate daily under a Lufthansa Cargo flight number. Together with its subsidiaries, Lufthansa Cargo offers customized, fast and efficient logistics solutions along the entire supply chain. In this way, the company fulfills its mission "Enabling Global Business" and connects markets and trading partners worldwide. Innovative technologies and investments in sustainability play a central role. In addition to a modern fleet and the use of sustainable aviation fuel (SAF), the focus is on continuous optimization of flight operations. In 2024, the company generated revenues of 3.26 billion euros and a transport performance of 8.5 billion freight tonne-kilometers. It currently employs approximately 4,200 people worldwide.