Press release -

How Minebea Intec Supports BYD’s Lithium Battery Evolution

As global demand for lithium batteries rises, Minebea Intec is providing advanced weighing systems for BYD’s 30,000-ton lithium carbonate project in Nanning, China. With load cells PR 6212 and mounting kits PR 6012, precise dosing and quality control are ensured.

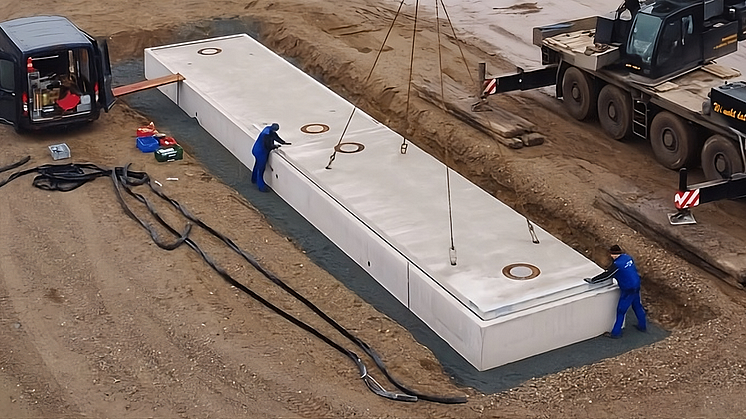

As the green wave sweeps the globe, demand for lithium batteries has surged due to their role as key energy carriers in electric vehicles and energy storage industries. To meet the growing demand, the leading new energy company BYD planned to build a 30,000-ton battery-grade lithium carbonate project in Nanning, Guangxi. After rigorous selection processes, Minebea Intec was chosen to provide weighing systems for lithium carbonate thickeners.

Enhancing Lithium Carbonate Production with Tailored Solutions

Within lithium carbonate production process, thickening plays a critical role in concentration enhancement, serving as a key quality control point. Weighing process allows customers to dose additives precisely, control product quality and document material usage. Minebea Intec tailored the solution based on multiple aspects and BYD precision requirements. Four load cells PR 6212 and mounting kits PR 6012 were installed under every vessel. The collected signals were then transmitted via a junction box to the weight indicator X2, subsequently uploaded to the DCS system for automated control of the charging and discharging process.

By installing load cells, an ordinary vessel transforms into a scale. Unlike static scales, the application accuracy of vessel weighing is influenced by multiple factors. The horizontal force caused by stirring is one of the major challenges.

Specifically chosen for its integrated constrainer, mounting kit PR 6012 can counteract horizontal force, implementing precision and stabile. Another f actor i s the fluctuating temperature. The lithium carbonate thickener vessels are located outdoors, therefore the expansion and contraction effects caused by seasonal changes should be considered. With a working temperature range of -30°C to 95°C, Minebea Intec load cells PR 6212 can perform reliably under challenging conditions.

Ensuring Safety in Challenging Chemical Production Environments

Safety is essential in the production of chemical products. Potential threats such as strong wind, thunderstorms and chemical corrosion cannot be ignored. When it comes to safety, Minebea Intec’s product can be trusted. The compact structure reduces installation height, and integrated lift-off protection provides anti-lift-off force up to 45kN, which eliminates the risk of tipping. In terms of corrosion resistance, the load cells PR 6212 are made of innovative 1.4418 stainless steel, offering superior corrosion resistance compared to regular stainless steel.

Unique inverted installation and sloped surface provide additional protection, which means the load cell can endure longer in humid and corrosive environments.

„With the long-standing history of the Minebea Intec brand, we have full confidence in product quality, reliability and safety.”

Gao Yuhong, BYD R&D Engineer

3,080 characters incl. spaces

INFOBOX

Key facts

The leading new energy company BYD required a weighing system for its newly-built lithium carbonate thickener. Minebea Intec’s solution, featuring corrosion-resistant, high heat resistance and lift-off protection, not only ensure the safety and reliability of the production process but also improve the accuracy and efficiency.

Application & Products

Minebea Intec configured a weighing system for nine BYD lithium carbonate thickeners using load cells PR 6212, Mini Flexlock kits, and weight indicators X2 to automate charge/discharge control and minimize horizontal forces.

- Load cell PR 6212/10t C1

- Mounting kit PR 6012/31S

- Weight indicator X2

- Junction box PR 6130/64S

Customer benefits

Load cell PR 6212 (1.4418 stainless steel) offers corrosion and heat resistance for longer life. The weight indicator X2 automates charge/discharge, boosting efficiency. Mounting kits add corrosion protection and reduce horizontal forces for safer weighing.

Topics

Categories

Minebea Intec is a leading global manufacturer of industrial weighing and inspection technologies. Headquartered in Hamburg, Germany, the company offers products and services that have stood for innovation, performance and reliability for more than 150 years. The product portfolio includes high-resolution platform scales, load cells, hopper and silo scales, checkweighers, metal detectors, X-ray and visual inspection systems as well as intuitive software solutions. Over 1,000 employees at 18 locations increase the precision and efficiency of industrial customers' weighing and production processes. A network of over 200 partners in 71 countries complements the global player's sales and service locations. The high performance and distinctive German quality are reflected in the brand promise "the true measure".

Minebea Intec is part of the MinebeaMitsumi Group, a leading supplier of high-precision production parts such as ball bearings and motors as well as high-quality electronic components such as sensors, antennas and IoT solutions. The Group, which is headquartered in Tokyo and has around 84,000 employees worldwide, reported consolidated net sales of 1,402,127 million yen (approx. 8.9 billion euros) for the 2024 financial year.