Blog post -

Providing Components and Solutions for the Automobile Society of the Future: Murata Manufacturing at the Automotive Engineering Exposition 2025

Murata Manufacturing Co., Ltd. (hereinafter, "Murata") participated at the Automotive Engineering Exposition (Yokohama City), Japan's largest automotive technology exhibition, on May 21, 2025. It is expected that electric vehicles (EVs) will become even more widespread in the medium to long term in the future. Against this background, Murata unveiled products and technologies that will contribute to improving the reliability of EVs. Moreover, car-related businesses are expanding. Accordingly, Murata is focusing our efforts on solutions and services in addition to components. We will take a look this time at the businesses of Murata that are active in these diversifying car and related fields.

Ideal for Power Semiconductor Temperature Sensing: Contributing to Improving the Reliability of EVs with a World-First Thermistor

As EVs become more widespread, the FTI series of automotive NTC thermistors are products that will lead to an improvement in the reliability of those vehicles. It is anticipated that these thermistors will be utilized as temperature-sensing components in places where power semiconductors are used such as EV inverters. We have already begun mass-producing them.

In recent years, the importance of highly efficient power conversion technology has been increasing due to the electrification and increasing performance of automobiles. In particular, there is a growing need for downsizing, higher efficiency, and higher power density in inverters and DC-DC converters for EVs. The key to meeting these needs is improving the performance and ensuring the reliability of power semiconductors.

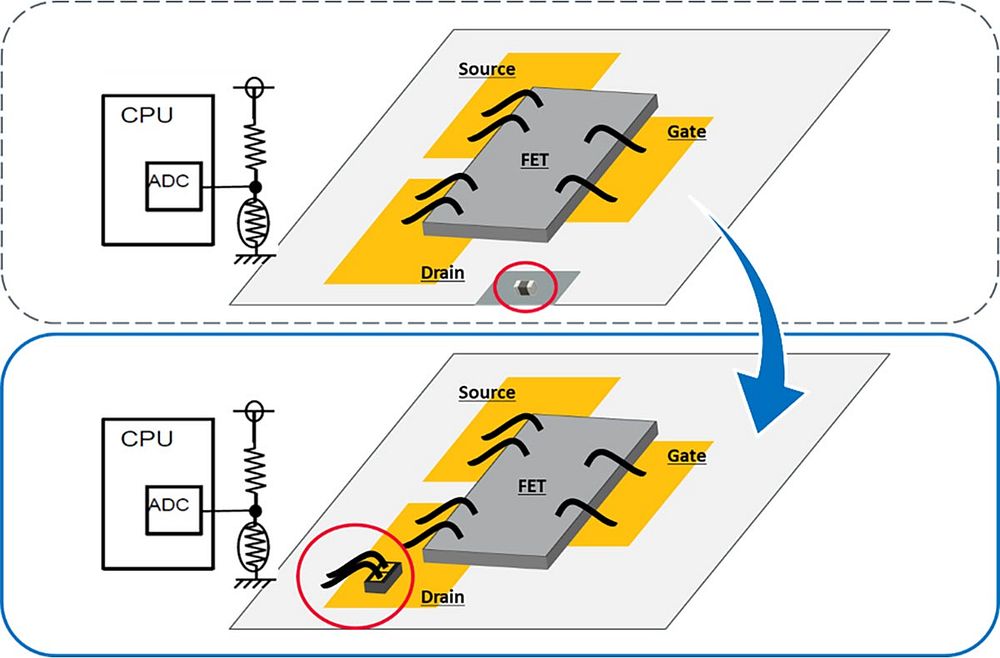

In general, NTC thermistors are used for temperature-sensing applications to prevent those power semiconductors from failing due to heat.

However, conventional thermistors lacked insulation performance. Therefore, they had to be mounted away from power semiconductors to which high voltages are applied. As a result, accurate and rapid temperature sensing was difficult. These constraints limited the ability to fully bring out the performance of power semiconductors.

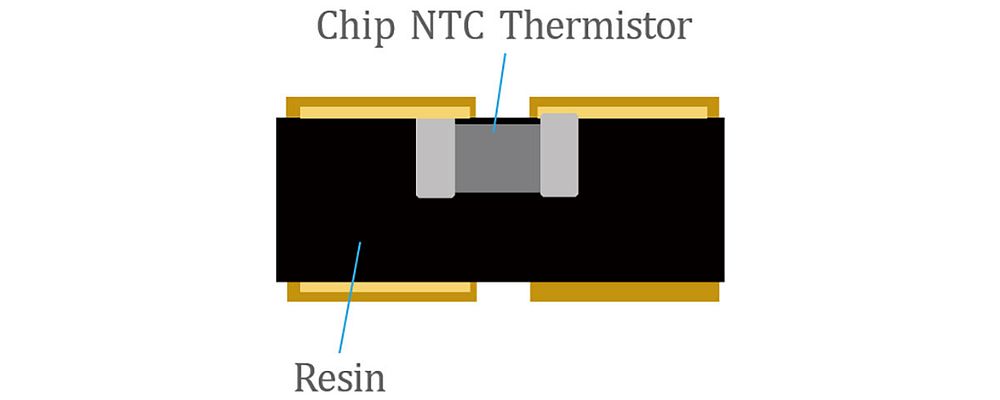

The FTI series has been newly commercialized by Murata to solve this problem. Covering these thermistors with resin realizes an insulation performance of 3.5 kV. It has now become possible to install them on high-voltage board lands where the power semiconductors are mounted.

The useable temperature range of FTI thermistors is up to 175°C. That means they can withstand high-temperature environments.

The internal chip thermistor is covered with resin. Together with this, it is joined to an external electrode for wire bonding. Adopting our unique highly reliable joining technology has allowed us to guarantee operation in a high temperature range up to 175°C.

This is a world-first product of a wire-bondable resin molded NTC thermistor guaranteed to withstand high temperatures up to 175°C.

Covering the thermistor with insulating resin also allows it to be used in places to which high voltages are applied

It is possible to install the thermistors in our FTI series closer to the power semiconductors than before. Therefore, it contributes to making the board more compact. A Murata staff member commented, "The space saved by making the board more compact can be utilized to expand the space inside the vehicle and to increase the size of the battery packs installed in the vehicle."

In addition, the automotive industry is beginning to pay attention to software defined vehicles (SDVs). These are vehicles whose functions are upgraded by updating the software installed in them. It is hoped that it will be possible to continue using vehicles for a long time by updating their software. Accordingly, it is said that there is a need for the hardware components installed in vehicles to have an even longer life.

A Murata staff member spoke to us, saying, "Accurately detecting heat reduces power semiconductor failures and other troubles. That means it becomes possible to continue using them for a longer time. In other words, it can also contribute to lengthening the life of vehicles." The components currently being mass-produced are solder-mounted types. However, we are aiming to commercialize a silver sintered-mounted type capable of withstanding higher temperatures in the future.

A Murata staff member emphasized, "Murata is the top manufacturer globally of NTC thermistors at present. However, we are also working to create new products for the automotive market to be able to meet the diverse needs of our customers. In this way, we want to contribute to the development of the EV market."

Murata's Technology also Supports Batteries: Contributing to Safety and the Environment with Deterioration Diagnoses

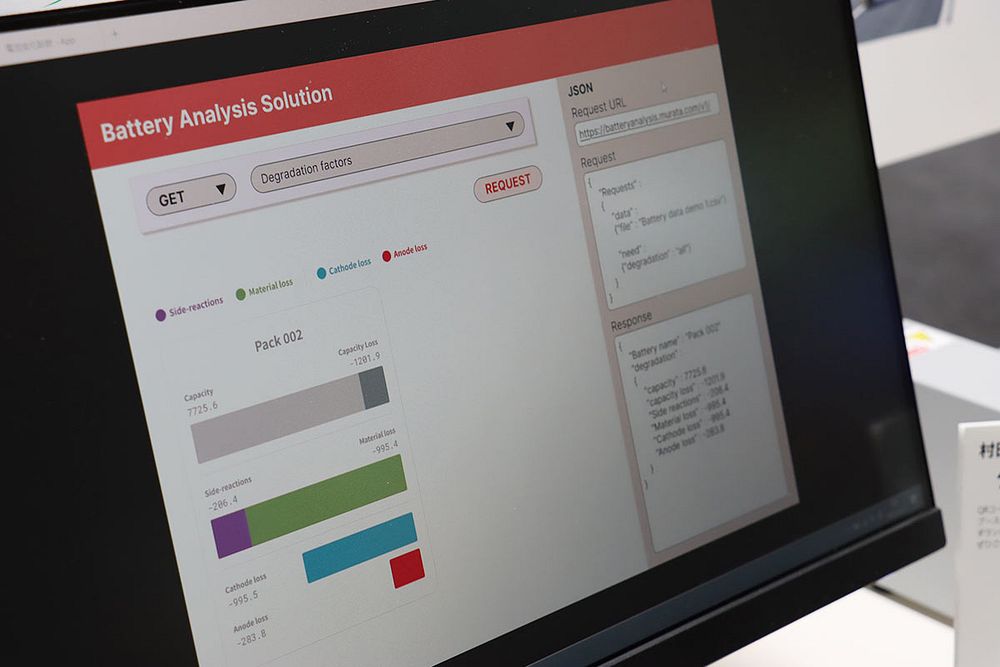

We also unveiled technology that supports the safe use of the batteries installed in EVs. This technology is Murata's Lithium Ion Secondary Battery Characterization and Battery Degradation Diagnosis System. This system can conduct non-destructive performance diagnoses with our unique simulation analysis. This analysis determines whether it will be possible to continue safely using batteries installed in EVs in the future and whether they are deteriorating to a dangerous state.

The system uses our unique algorithm to acquire and analyze data during charging. It is even possible to conduct detailed diagnoses such as in terms of whether the cause of the deterioration is the positive or negative electrode. A Murata staff member told us, "Compared to deterioration diagnoses based on usage history that require extensive machine learning, it is possible to introduce this system at low cost. It is compatible with batteries from various manufacturers." It takes about four hours to conduct the deterioration diagnosis. A Murata staff member commented, "It is possible to improve the driving range, driving time, and other elements of EVs by accurately conducting diagnoses on batteries so that they can continue to be used safely for a long time."

It is also a promising solution from the perspective of the global environment. Cobalt, nickel, and other rare resources are used in EV batteries. A Murata staff member said, "This is a solution that also contributes to the environment by encouraging recycling at the appropriate timing through deterioration diagnoses."

Supporting Expansion of the IoT Business in Southeast Asia: Utilizing Traffic Volume Measurement Know-how

We are further expanding our range beyond vehicle-related business. We have also begun offering solutions to help Japanese IoT device manufacturers to develop their data businesses in Southeast Asia. The impetus for this was the Traffic Counter System. This is a traffic volume visualization system that Murata has been working on in Indonesia.

Murata developed this system in 2013. Since then, the system has acquired traffic volume, vehicle model information, and other data in Indonesia and elsewhere in Southeast Asia. We analyze this data and then sell it to local governments and other organizations.

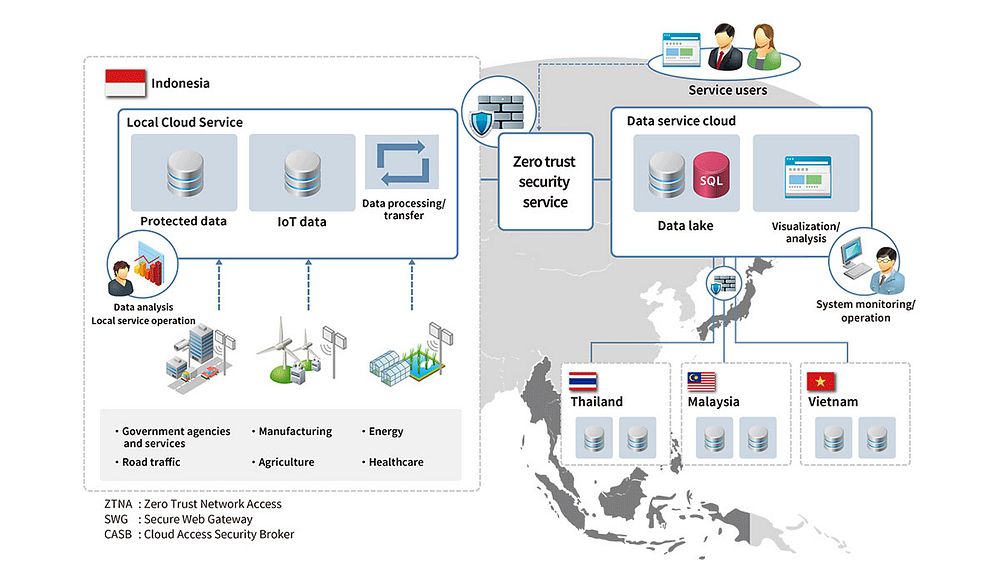

This experience led to the new business we will now look at called our "IoT Data Service Platform." A Murata staff member spoke with us about this service, saying, "It is necessary to comply with local standards, such as the data protection laws in each country, when developing a data business. We are already able to comply with such regulations and requirements. As such, we wondered whether we could serve as a bridge for when Japanese IoT device manufacturers advance into Southeast Asia by providing this know-how."

We have set up a structure that enables the data business to comply with local regulations for Indonesia, Thailand, Malaysia, and Vietnam by leveraging our track record of developing business in Southeast Asia.

Another feature of this service is that we can provide functions from the provision of sensors to collect data to cloud services to utilize that data, and the monitoring and operation of systems in a one-stop service. We are collaborating with the Internet Initiative Japan (IIJ) organization that we partnered with on the Traffic Counter System for cloud and other services.

A Murata staff member expressed hopes for future developments, saying, "If the number of companies utilizing this IoT platform increases and we proactively collaborate with them, we will be able to achieve things that Murata could not do alone."

One such example is deterioration diagnoses for bridges and other infrastructure. We believe that by combining data on traffic volume taken from Murata's Traffic Counter System and other services with vibration data such as the degree to which bridges sway, it will be possible to utilize this service to determine the deterioration status of infrastructure according to the traffic volume. A Murata staff member commented, "Combining data in this way should allow us to provide new value to the automobile society."

Objectively Indicating Fatigue Levels: Contributing to the Realization of Comfortable Travel Spaces

We also exhibited the MF100 Fatigue Stress Meter. This device objectively assesses fatigue and stress levels that could only be judged subjectively in the past. (*The MF100 Fatigue Stress Meter is not a medical device. In addition, it is not intended to prevent, diagnose, or treat disease.)

This meter visualizes the state of the autonomic nerves by analyzing vital data acquired with a dedicated device and then correcting it with big data. Specifically, it uses a combination of optical and electrical sensors to analyze the fluctuations in the heartbeat intervals (the interval between each heartbeat) on servers. Analyzing these fluctuations allows us to see the deviation value of the autonomic nerve function (fatigue) and the balance between the sympathetic and parasympathetic nerves (stress level). It takes about two minutes to perform the measurement.

Many companies have adopted this technology up to now from the aspect of health and productivity management. However, automotive-related companies and others have been asking about it from the perspective of comfort.

A Murata staff member commented, "As autonomous driving technology advances, the people in vehicles will no longer need to operate them. As a result, the way vehicles are being utilized is also starting to change."

Specifically, it seems it may be possible for people to use their time in vehicles to watch movies while traveling in them or to relieve their stress by relaxing as though in a hotel.

A Murata staff member told us, "We want people to use this technology to verify areas relating to comfort such as automobile interiors and ride comfort."