Precision Alignment and Balance isn’t Important – Unless you care about budgets and the reliability of your rotating assets.

I read an interesting article in the June/July 17 issue of Uptime Magazine. It was titled “The Reliability Impact Within the P-F Curve” by Randy Riddell. Randy is the Reliability Manager for the SCA Barton Mill in Alabama.

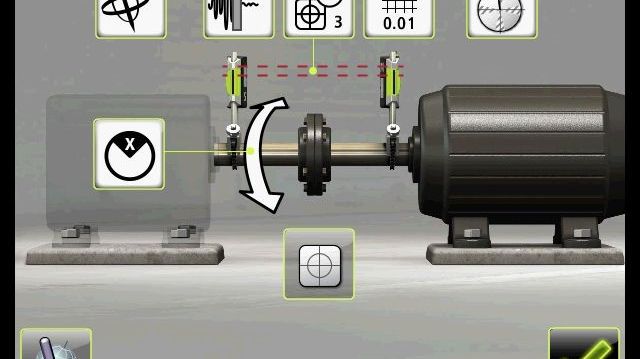

I encourage you to read the full article (https://reliabilityweb.com/articles/entry/the-reliability-impact-within-the-p-f-curve). The article includes the following graphic t