Blogginlägg -

What is Extended Alignment function?

When training clients to use Fixturlaser Verti-Zontal Alignment Process we show taking the 3rd measurement at a horizontal position, typically at 3 o’clock. This is simply for expediency and is NOT a requirement as Fixturlaser Shaft Alignment Systems can take measurements at any position due to the inclinometers in M & S sensors.

Why Extended Alignment function?

If possible we want to have the sensors in a horizontal plane when the live screen is activated so the sensors are in position to monitor the horizontal correction. For rotating machines with large mass or that are difficult to position precisely, this may be time consuming and/or not possible. Other shaft alignment applications may have obstructions at both the 3 & 9 o’clock positions.

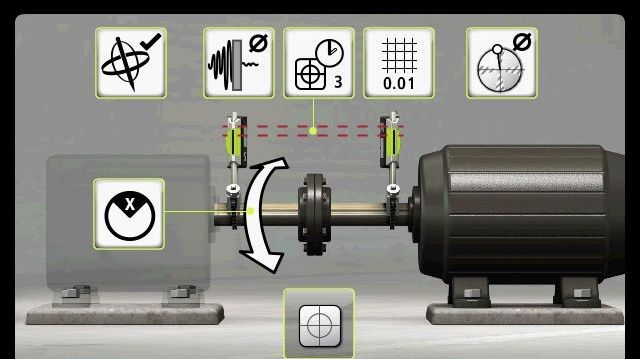

Should this occur the Fixturlaser NXA will advise the alignment tech when the sensor position is not ideal to monitor the horizontal correction with this screen.

For these situations the Extended Alignment Function or Utility should be turned on. Extended Alignment allows the horizontal position to be monitored as long as the sensors are within +/- 45o of the 3/9 o’clock positions. (Also +/- 45oof the 12/6 o’clock positions when making live vertical adjustments on machines mounted on adjustable chocks.) When using Extended Alignment, diagonal red stripes will be displayed on the coupling and foot value fields.

FIXTURLASER NXA Extended Alignment function

The system allow recording samples from 3 measuring positions at any rotational angle.

The measuring positions has to be separated with at least 60° rotation between each other.

To get live view during corrections, the sensors has to be in either 9 or 3 o’clock (within ± 5°) for horizontal and 6 or 12 o’clock for vertical correction.

Problem:

In some applications, it is not possible to reach these positions for different reasons:

Obstructions (e.g. pipes, coupling covers, foundations, electrical wiring, etc.) that makes it impossible to place the sensors in the required rotational angle.

It’s difficult to control or stop the machine at the required rotational angle!

The function makes it possible to ”enlarge” the angles where you can have Live View during corrections.

How does it work?

The function makes a software compensation of the shown values based upon the actual rotational angle of the sensor during correction.

Fixturlaser NXA has the Extended Alignment function! http://www.fixturlaser.com/Shaft-Alignment/Fixturlaser-NXA/FIXTURLASER-NXA-Pro/