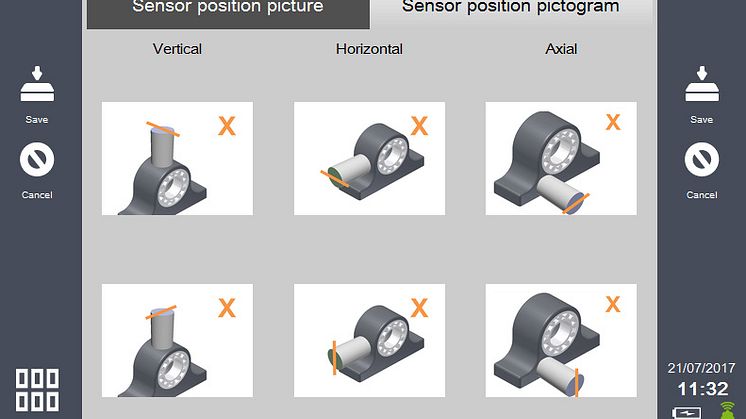

X, Y, Z Axis. What do they stand for?

Everything must have perspective, a point of view, to be communicated. To communicate the three spatial dimensions, we use the X,Y, Z coordinates.

Everything must have perspective, a point of view, to be communicated. To communicate the three spatial dimensions, we use the X,Y, Z coordinates.

Fixturlaser SMC you can achieve a second level diagnosis on any machine without help from a professional vibration analyst. It just took a tool that empowers mechanics to more quickly troubleshoot a machine at the touch of a button.

“Fix the easy things first” is an old adage, and a familiar term to some maintenance technicians. In many cases, the “easy to fix” things are where the problems are.

When we say, “Your laser displays in mils”, we’re asked, “What’s a mil?”

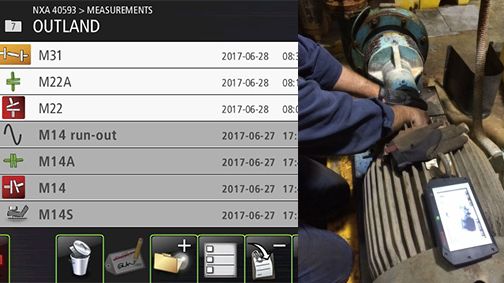

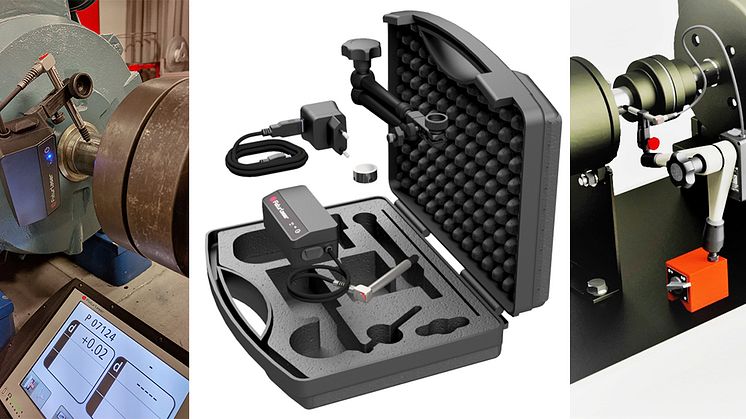

Like no other, the Fixturlaser SMC is a portable, machinery diagnostic tool that allows mechanics and maintenance technicians to check the health of any rotating machine, as needed, in a matter of minutes. It requires no special training or certification and generates straightforward, simple machine diagnostic reports with both confidence and severity levels.

So, what is misalignment costing you? In this case, alignments were taking up to 12 hours. 12 hours of frustration and often unsuccessful.

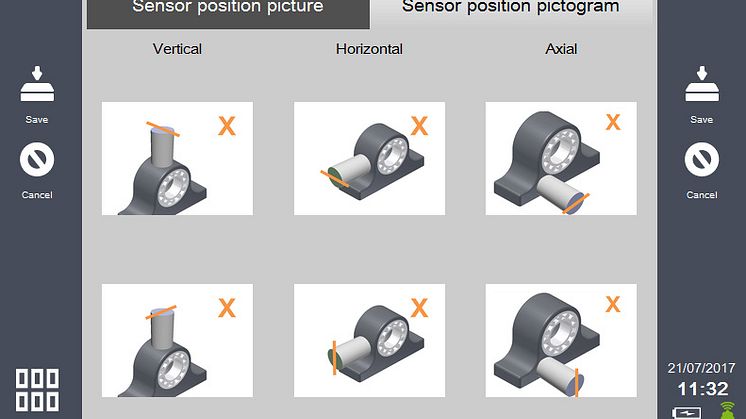

Coupled with the NXA Professional, it’s a run out probe. A dial indicator. A micrometer. A documenter. And a great diagnostic troubleshooting tool!

This is an obvious statement and most of us know what happens when we do “ASSUME” with most things in life. However, we (The VibrAlign Trainers) see assumptions being made quite often during a precision shaft alignment.

Several years ago, I read a book titled “A Millwright’s Guide to Motor/Pump Alignment” by Tommy “T-Hammer” Harlon (available through Industrial Press). Tommy’s book deals with a

While at facilities across the country I noticed a lack of understanding regarding the need for precision alignment of offset shaft driven rotating equipment. I myself have seen electricians and mechanics alike becoming frustrated trying to determine the cause of speed fluctuations and vibration in offset shaft driven equipment.

Have you ever struggled with a precision shaft alignment, even though you did everything right? (Preformed the pre-alignment steps, controlled backlash, etc., etc.) So, what was different? Maybe it was pipe strain.

The Fixturlaser Runout Probe, an accessory for the Fixturlaser NXA Pro and Fixturlaser NXA Ultimate, is an electronic tool designed to detect and measure shaft runout and pipe strain. Runout and pipe strain are often overlooked, but when present they can confound the measurement and correction of shaft alignment.

The Fixturlaser NXA Pro has been selected as the laser shaft alignment tool to be used in the Industrial Mechanic Millwright competition at this year’s WorldSkills event, being held in Abu Dhabi on October 15-18.