Pressmeddelande -

Fixturlaser Runout Probe

New Fixturlaser Runout Probe

Safe and reliable measurement of axial and radial runout using a smart probe

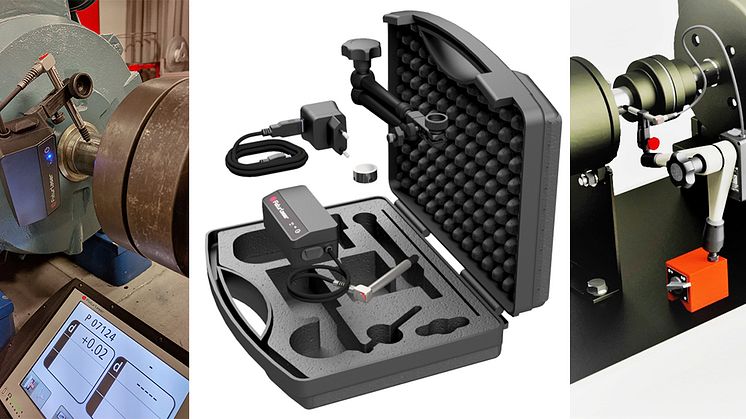

Fixturlaser expands the range of measurement functions with the Fixturlaser Runout probe for measuring axial and radial runout checks on flanges and shafts.

“Fixturlaser Runout Probe is of wireless design, and has a superior interface with quick mounting” says Peter Strömberg, Head of R&D.

Runout of machine shafts can be due to worn bearings/ bearing clearance, a bent shaft or a damaged surface. Runout on the coupling directly impacts on the machine parts and results in worn bearings and production stops. The Fixturlaser Runout Probe is an accessory for Fixturlaser NXA and the hardware in the probe is equipped with Bluetooth that connects with the Fixturlaser NXA.

Fixturlaser Runout Probe is multifaceted and can also perform, checking movements on machine feet (soft foot), lift check, checking movements due to pipe strain, thermal growth on machine casings, eccentric or skewed mounting of coupling hubs

The probe is easily attached using a standard measuring stand with a magnetic base.

Fixturlaser Run-out probe is a high-precision instrument which show readings down to 0,001 mm combined with a large measuring range of 5 mm.

For product-related questions please contact:

Hans Svensson CEO

Hans.svensson@acoem.se

Relaterade länkar

Ämnen

Kategorier

ACOEM AB is a global player and a leader in developing innovative, user-friendly equipment for shaft alignment. By helping industry worldwide to become perfectly aligned, and eliminating anything that might not be, we minimize unnecessary wear and production stoppages. This will ultimately make our customers more profitable and our environment more sustainable.