Top Tips for Leveling Your CNC Machine

CNC machine leveling is an essential function. Optimizing a machine's capability and producing high-quality parts is a key element of its capability.

CNC machine leveling is an essential function. Optimizing a machine's capability and producing high-quality parts is a key element of its capability.

There are many tools on the market to use in conjunction with lubrication – mechanic’s stethoscopes, “smart” grease guns which use ultrasonic, or just an ultrasonic tool itself. High-frequency vibration measurements can also do this.

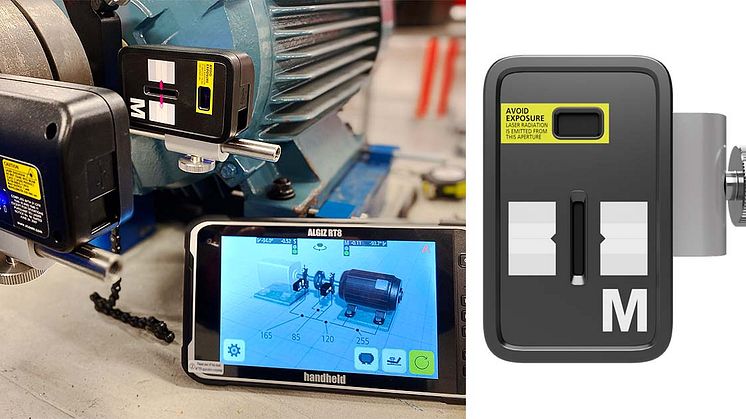

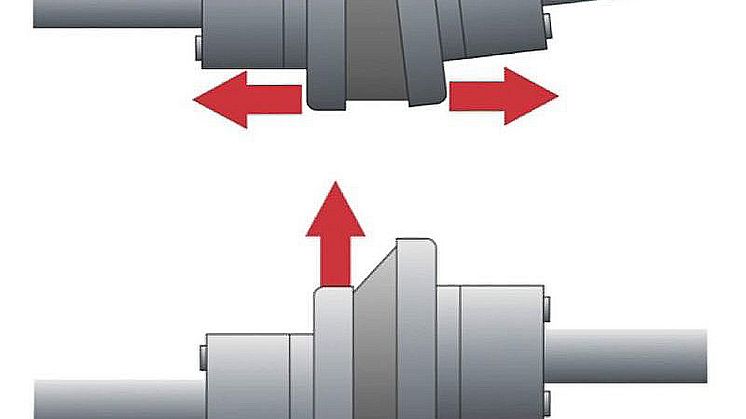

When using a straightedge to perform a shaft alignment you won’t see angular misalignment.

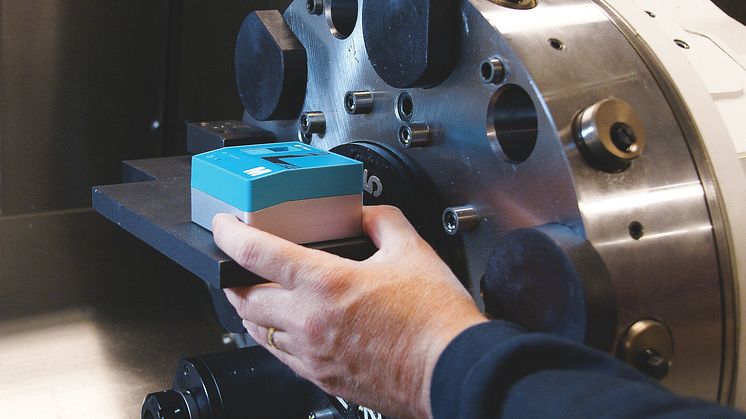

ACOEM AT-100 NEW entry-level smartphone and tablet-based alignment tool that utilises the latest sensor technology and the renowned Acoem user interface, GuideU™

To calculate the cost of misalignment, first determine the cost of the machine’s downtime.

We have several times discussed the differences between coupling alignment tolerances and precision shaft alignment tolerances. As stated in those text the coupling manufacture’s tolerances are for the coupling. As maintenance professionals we are concerned with the coupling, however we are more concerned with the bearings in the machines.

Belt Drive advantages - quiet in operation, require no lubrication, and are relatively cheap to produce.

The NXA Runout Probe is a simple electronic tool designed to detect and measure shaft runout. The new tool represents a unique application of a linear variable displacement transducer (LVDT) to provide an easy-to-use but highly accurate measure of machinery problems that can confound the measurement and correction of shaft misalignment

When everything is running smoothly, digging for the necessary protocols or procedures may feel cumbersome, but doesn’t necessarily set off bells and whistles that a bigger problem may be lurking.

Predictive maintenance involves scheduled testing on regular intervals.

A key thing to understand when it comes to belts is proper sizing. Whether you are using a correctly-sized belt for your machine will have a significant impact on the machine’s ability to function at an optimal level.

We’ve identified 6 common machine faults you’ll likely encounter on your maintenance routes.