Pressmeddelande -

Belt Drive Basics

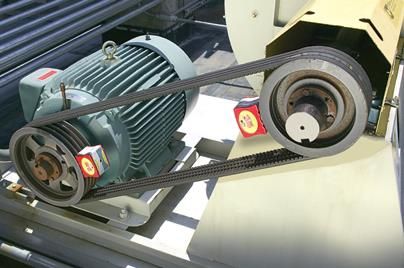

All over the world belts provide power transmission in transportation, industrial and commercial machines. Belt drives for power transmission are classified as frictional drives. The belt transmits power by contacting the sides of the drive and driven sheaves. Belts are available in several styles: Flat belts, v-belts, Synchronous (timing) belts and Multi-ribbed belts. While belts are used in many different applications, they are not good for every situation. Here are some advantages and disadvantages to using belt drives.

Belt Drive Advantages

- Large range of speeds are available.

- Belts allow flexibility ranging from high horsepower, slow and high-speed drives.

- Belt drives are usually cheaper than chain drives for low horsepower and low ratio purposes.

- Belts do not need to be lubricated.

- Flat belts are the best choice for extremely high-speed drives.

- Belt drives cushion shock loads and load fluctuations.

- Belts will slip when overloaded preventing damage to shafts, keys and other parts of the machine.

Belt Drive Disadvantages

- Belts cannot be used in applications where precise timing and speed are required due to belt slippage (Synchronous belts can be used here).

- Belts can easily be damaged by grease, oil, abrasive materials, high heat and certain chemicals.

- Belts can have high noise levels.

- Loose and worn belts can cause high vibration in machines.

Understanding the advantages and disadvantages of belt driven machinery can help you choose and properly maintain machines in your plant. It is a common misconception that proper belt installation and maintenance requires little skill. This is far from the truth.

Let us know if you would like to schedule some training on Belt & Sheave installation and maintenance.

Relaterade länkar

Ämnen

Kategorier

Together with 150 distributors, our 800+ employees work across 26 offices, 5 manufacturing facilities and 3 R&D centres in 11 countries

Acoem links possibilities with protection.

For more information visit acoem.com.