Cutting Corners Can Affect Safety and MTBF

Precision shaft alignment is area of importance. As studies have shown not preforming precision shaft alignment of rotating machinery will most certainly lead to early equipment failure.

Precision shaft alignment is area of importance. As studies have shown not preforming precision shaft alignment of rotating machinery will most certainly lead to early equipment failure.

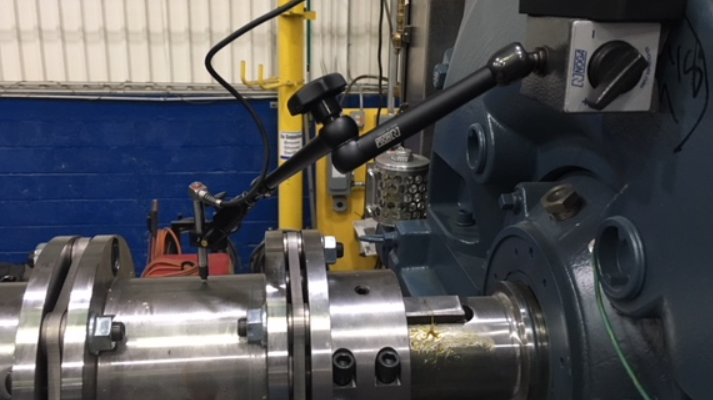

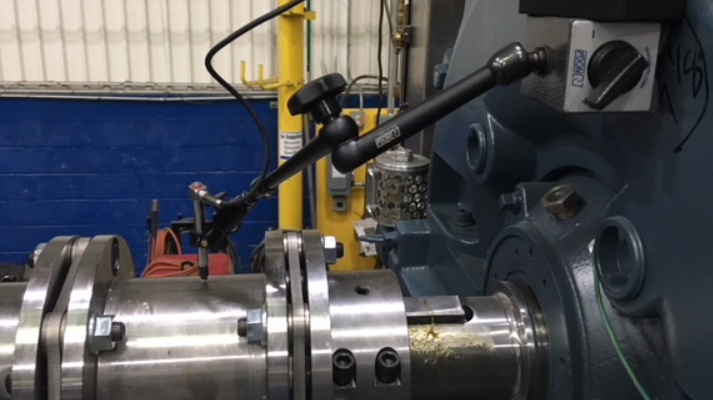

When measuring runout with the Fixturlaser NXA Runout Probe the best practice is to first measure the coupling for non-circular rotation. If runout is detected, the next step is to measure the shaft to determine if the runout is caused by a bent shaft versus an eccentric coupling

Laser Shaft Alignment systems should be properly maintained for optimal performance. Dirty sensors (laser and detector lens) can lead to non-repeatable measurement results. All system components should be stored properly in the carry case to prevent damage to said components.

Even when we are going to perform an alignment on a piece of equipment, it is a good practice to record a pre-alignment measurement to document or maybe explain any possible issues later.

The Fixturlaser PAT uses the pulley groove as the reference, allowing you to achieve a precise belt alignment which reduces wear, bearing failures and vibrations.

Proper use of any tool is essential to success in achieving your desired goal. Many tools have optional configurations to adapt that tool to your needs. Fixturlaser Precision Alignment Systems are no different. The alignment tools produced by Acoem/Fixturlaser are second to none in ease of use. The Acoem AB design engineers do all they can to provide the end user with an alignment tool that can be

Teknisk säljare

till mellersta och norra Sverige

Välkommen till vår värld! Ända sedan starten 1984 har ACOEM AB hjälpt företag välden över att uppnå en mer effektiv och lönsam produktion. Vår säljare i mellersta och norra Sverige, Per Östundh skall nu efter många framgångsrika år gå i välförtjänt pension och vi söker nu hans ersättare.

"Efter att ha arbetat i 14 år som försäljningsingenj

Regardless of whether upkeep specialists are utilizing Rim and Face or Reverse Dial Indicator Sets, or any of the laser shaft arrangement frameworks they are on the whole making progress toward a similar result. Which is to have the rotational shaft centerlines of the driver and driven machine(s) adjusted (collinear) in the vertical and flat planes when the machines are working.

When laser alignment tools are not repeatable, it’s not the laser – IT’S YOU.

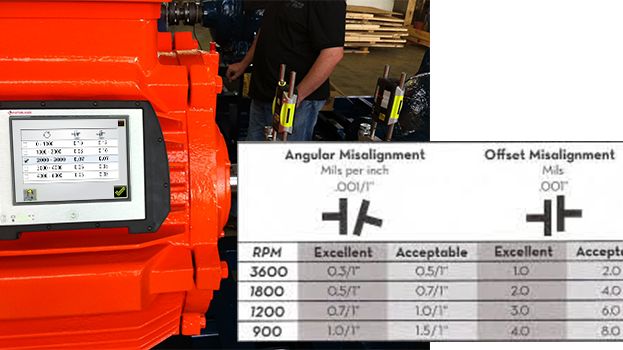

The initial set of alignment results indicated horrible angular misalignment (14 to 16 times tolerance) and offset misalignment (6 to 8 times tolerance) in the vertical and horizontal planes

Thermal growth is not rocket science. However, it is often misunderstood. We see people causing harm by compensating for thermal growth incorrectly.

The Fixturlaser SMC is designed to be used by machinery mechanics to give a clear and accurate automatic diagnosis of rotating equipment. Requires no vibration expertise or internet connection.

The Fixturlaser SMC is a powerful machinery diagnostics tool that requires no vibration expertise. After the user has built their machine in the box, the SMC will diagnose the machine's faults in a matter of seconds utilizing the Accurex automatic diagnosis software.

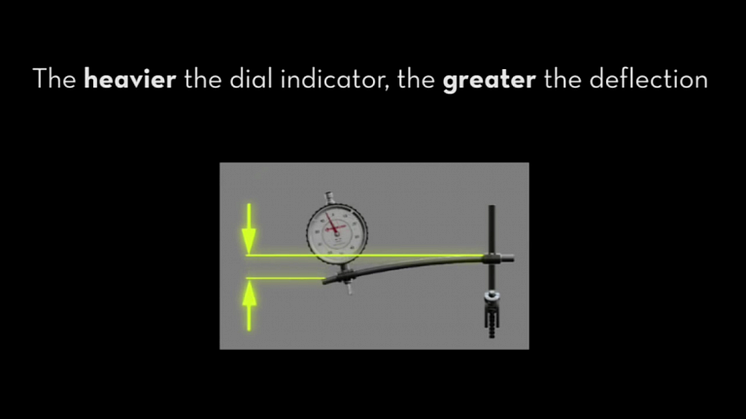

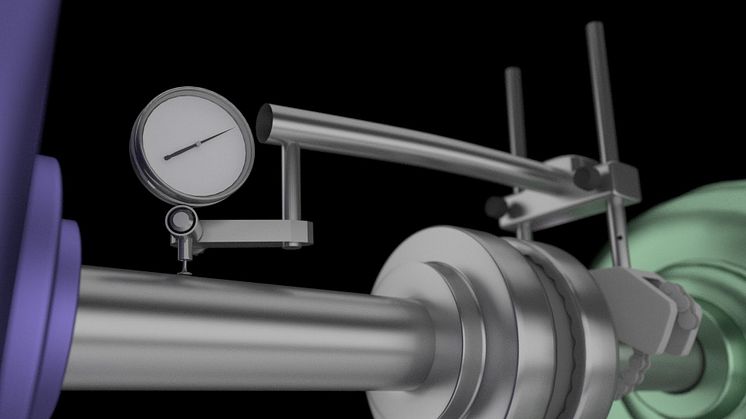

Dial indicator bar sag describes a bending of the hardware used to support a dial indicator or other part which spans the coupling. The bending action occurs as a result of gravity and cannot be totally eliminated in almost all cases of alignment.

Fixturlaser have done what we will to form the exactness shaft alignment method faster and easier for the user of our tools. To help maintenance personnel throughout alignment a tolerance table “pops up” on the unit screen (of our tools) once getting into dimensions for the machines being aligned. The tolerances square measure supported industry standards.

The Runout Probe provides a digital linear displacement measurement, much like a dial indicator, but with the added benefit of electronic documentation through the Bluetooth connection with the NXA Display Unit.

Hold down bolts are designed to keep the machine in position after a precision alignment is performed. Jacking bolts are designed to help position a machine during the alignment. Jacking bolts are not designed nor should be used to maintain the position of a machine, that is the job of the hold down bolts. Let’s look at the design intent of each type.

So what is bar/rod sag? Simply put, it is how much the dial indicator mounting bar deflects when the rim dial indicator is install. How much the bar/rod deflects depends upon the type of bar (solid or tube), the length of the bar and weight of the dial indicator.

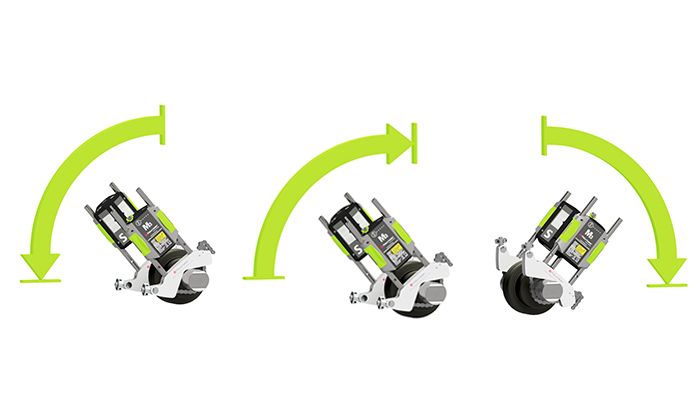

Unbalance and runout are two terms that we hear frequently in the predictive maintenance community. Both unbalance and runout can be serious issues and need to be addressed to prevent inefficient functioning and damage to machines.