Using Your Laser Alignment Tool to Measure Pipe Strain Induced from Tightening Flanges

Using Your Laser Alignment Tool to Measure Pipe Strain Induced from Tightening Flanges

Using Your Laser Alignment Tool to Measure Pipe Strain Induced from Tightening Flanges

The NXA Runout Probe was introduced as an accessory to the NXA Pro and Ultimate alignment tools. As originally envisioned, the runout probe was designed with shaft and coupling runout measurements, and direct soft foot measurements in mind.

Often the OJT portion of our training classes begins with an alignment check of a rotating piece of machinery in the client’s facility. This comes after numerous alignments in the classroom, on the training fixtures, performed by the attendees.

They are then ready to apply their skills learned on the classroom training equipment in their plant. A typical scenario for the OJT training is that th

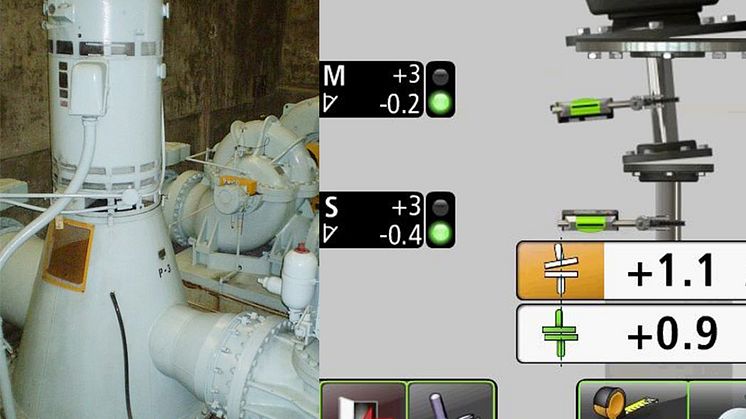

The FIXTURLASER Laser Kit consists of two wireless sensor units utilizing two line lasers. The use of line lasers simplifies the setup process minimizing setup time. To make it even easier, the sensors comes pre-mounted on its fixtures and pre-set to the most common setup.

OmniView is also valuable on vertically mounted machines.

The Fixturlaser Smart Machine Checker is designed to be used by machinery mechanics to give a clear and accurate automatic diagnosis of rotating equipment. Requires no vibration expertise or internet connection.

Pre-Alignment Steps are the shaft alignment medication that reduces frustration and saves time in the long run!

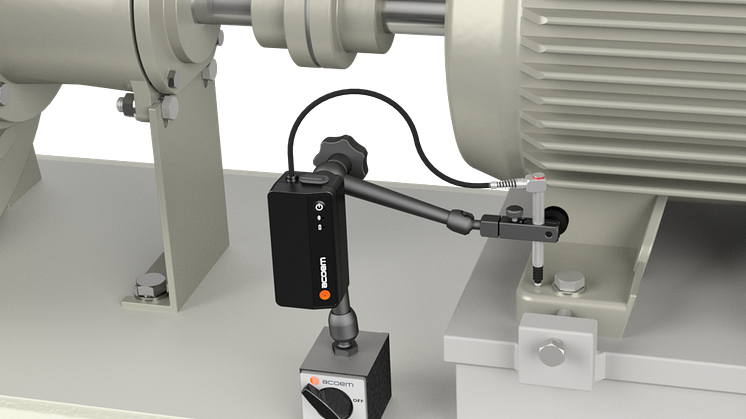

ACOEM Fixturlaser proudly presents the predictive maintenance solution you've been waiting for, the RT-300. This machine reliability tool helps with precision shaft alignment and all machine diagnostics.

The augmented mechanic’s solution – RT-300 – is a smart reliability tool that combines on-the-spot machine diagnostics with tools for pre-alignment and precision shaft alignment, minimizing the time from fault diagnostics to corrective actions.

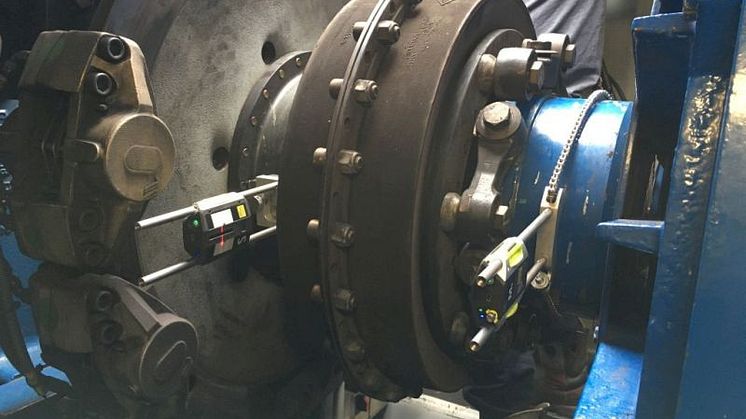

Precision shaft alignment of wind turbine generators mounted on adjustable chocks is as straightforward as when aligning rotating machinery mounted on chocks down at ground level.

In the case of a recent NXA Training Class in a Vestas V82 we knew before going up-tower that one revolution of the adjustable chocks equals 1mm. Also, as there are 6 holes in the chocks, we calculated that the hole t

Vibration analysis is a useful way to monitor machine health. Many plants have implemented regular vibration analysis plans to ensure the condition of their machines is being checked at regular intervals and so, if an issue comes to light after spectral analysis, a solution can be pursued.

When analyzing vibration, it is important to be familiar with several terms. These are:

Frequency

Disp

When performing vibration analysis, it is observed that machines with VFD drives have a more frequent occurrence for changing motor bearings. If you’ve been diligent in the installation and maintenance of these machines, ensuring the alignment and balance are within specification and the bearings are properly lubricated, but still have frequent bearing failures, it may be your VFD drive.

I’ll

If you’ve worked with machine tools before, you’ve likely heard the terms coaxiality, runout, cylindricity, roundness, and total runout, but do you know what each means?

In this post we will lay out each of these terms so that you know what each means and so you are able to grasp the difference between them, which will hopefully be helpful on the job.

Let’s begin with roundness. This can als

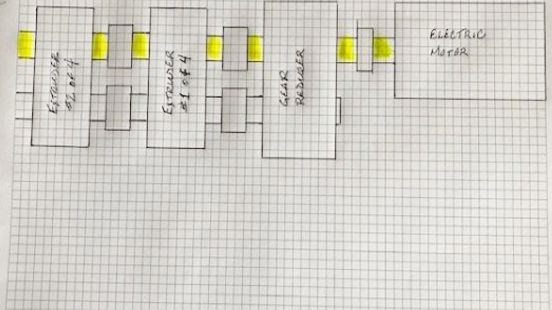

For the field portion of a recent training class, the decision was made to check the alignment on a plastic extruder. At first glance, checking the alignment of the motor shaft to gearbox input shaft is pretty straightforward. However, the output side of the gearbox had two shafts, so maybe this is not so straightforward. And to complicate things a little more, there are three more chambers couple

We want to offer some helpful maintenance tips from our trainers in a single blog post. This blog is a collection of useful troubleshooting tips, maintenance reminders, and pieces of advice from people who have been in the maintenance industry for many years and have seen a thing or two and want to pass their knowledge on to you!

We have categorized the tips below so that you can focus on the

Fixturlaser LEVEL is used for levelling machines or machine parts during installation and gives accurate measurement results. The measuring sensor measures the angular deviations from the surface in two axes using a wide measurement range (± 50 mm/m), high accuracy and with a resolution down to 0.01 mm/m.

When performing the Ariel ER-82 Top Plane Compressor Frame Measurement, surrounding reciprocating compressors in operation may cause repeatability issues due to excessive vibration.

Establishing good habits with sensor placement will get you one step closer to determining the health of any machine.

Recently, we was called to consult with a customer to recommend a procedure and alignment tools for a very long-distance vertical pump alignment. First, we will describe the machine and then how we aligned it. This large raw sewage pump machine train begins at the driver level. In this plant, floor levels are described by relationship to sea level. At the top level (+35), the primary mover, a

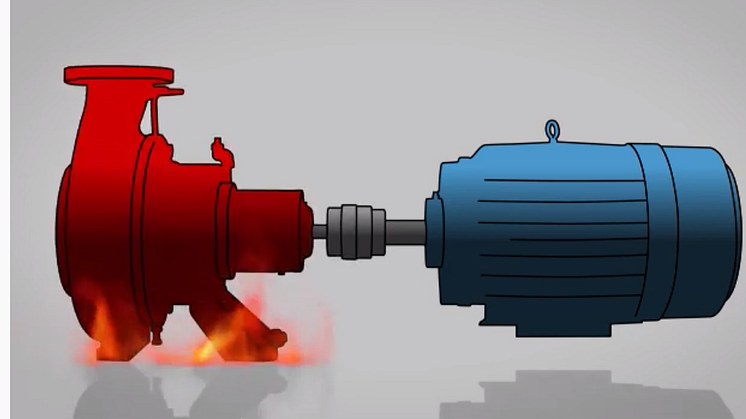

In shaft alignment, machines that run hot often have In shaft alignment, machines that run hot often have thermal growth targets. Thermal targeting simply means that the shafts may be misaligned while at room temperature, but as they heat up to operating temperature, they will “grow” into alignment.

But where does the thermal growth target come from?

Many times, the machine manufact