Understanding the Need for Offset Shaft Alignment

There are two parts that must be understood, proper phasing and angularity of the input and output shafts.

There are two parts that must be understood, proper phasing and angularity of the input and output shafts.

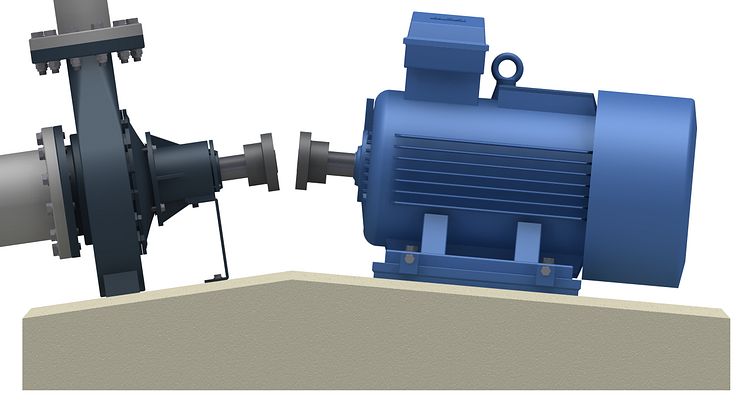

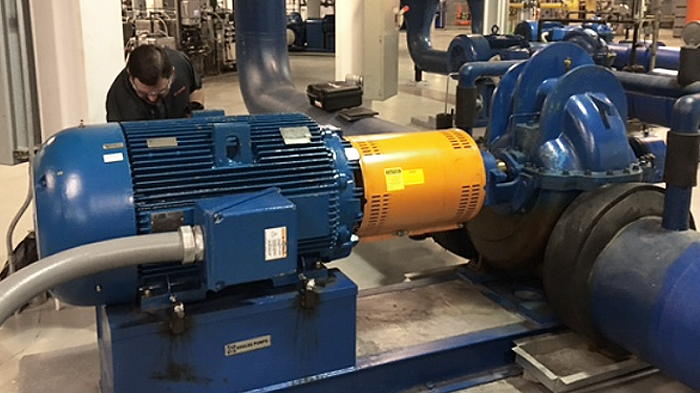

There were huge differences between coupling alignment tolerances and precision shaft alignment tolerances during a recent Acoem RT-300 training class. Electric motors and centrifugal pumps fitted with grid couplings of model 1070T were aligned at 1800 RPM. A contractor performed the initial alignment on this fairly new installation.

Predictive maintenance involves scheduled testing on regular intervals.

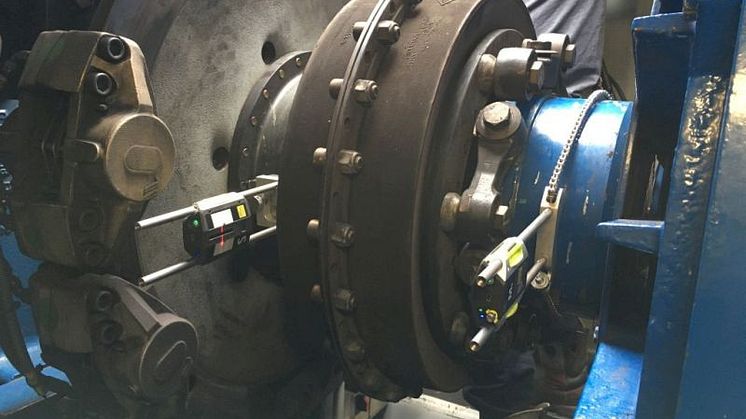

During a recent class in a shipyard, there was a need to perform a Cardan Shaft Alignment in a boat with very little space to work in. It also required shooting the lasers through a hole in a bulkhead.

Looking from the S sensor through the bulkhead at the M Sensor mounted on engine output shaft

S Sensor mounted on propulsion unit

It was a challenge, but the guys rose to it and the result

Using Your Laser Alignment Tool to Measure Pipe Strain Induced from Tightening Flanges

Precision shaft alignment of wind turbine generators mounted on adjustable chocks is as straightforward as when aligning rotating machinery mounted on chocks down at ground level.

In the case of a recent NXA Training Class in a Vestas V82 we knew before going up-tower that one revolution of the adjustable chocks equals 1mm. Also, as there are 6 holes in the chocks, we calculated that the hole t

Vibration analysis is a useful way to monitor machine health. Many plants have implemented regular vibration analysis plans to ensure the condition of their machines is being checked at regular intervals and so, if an issue comes to light after spectral analysis, a solution can be pursued.

When analyzing vibration, it is important to be familiar with several terms. These are:

Frequency

Disp

When performing vibration analysis, it is observed that machines with VFD drives have a more frequent occurrence for changing motor bearings. If you’ve been diligent in the installation and maintenance of these machines, ensuring the alignment and balance are within specification and the bearings are properly lubricated, but still have frequent bearing failures, it may be your VFD drive.

I’ll

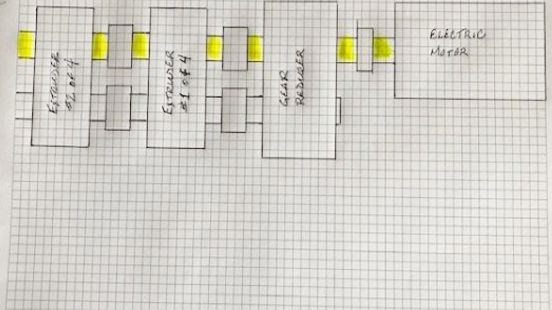

For the field portion of a recent training class, the decision was made to check the alignment on a plastic extruder. At first glance, checking the alignment of the motor shaft to gearbox input shaft is pretty straightforward. However, the output side of the gearbox had two shafts, so maybe this is not so straightforward. And to complicate things a little more, there are three more chambers couple

We want to offer some helpful maintenance tips from our trainers in a single blog post. This blog is a collection of useful troubleshooting tips, maintenance reminders, and pieces of advice from people who have been in the maintenance industry for many years and have seen a thing or two and want to pass their knowledge on to you!

We have categorized the tips below so that you can focus on the

When performing the Ariel ER-82 Top Plane Compressor Frame Measurement, surrounding reciprocating compressors in operation may cause repeatability issues due to excessive vibration.

Recently, we was called to consult with a customer to recommend a procedure and alignment tools for a very long-distance vertical pump alignment. First, we will describe the machine and then how we aligned it. This large raw sewage pump machine train begins at the driver level. In this plant, floor levels are described by relationship to sea level. At the top level (+35), the primary mover, a

This is as much a title for a blog as it is a question. One our Technical Trainers once stated that to align rotating machinery, they must first be alignable. What is meant in part by this is that when we have a collinear tolerance of 0.5mil /1” angularity and 2.0 mils offset, the machines must be mounted to a stable foundation to be able to hold the tolerance.

Flexion of the base in some cases

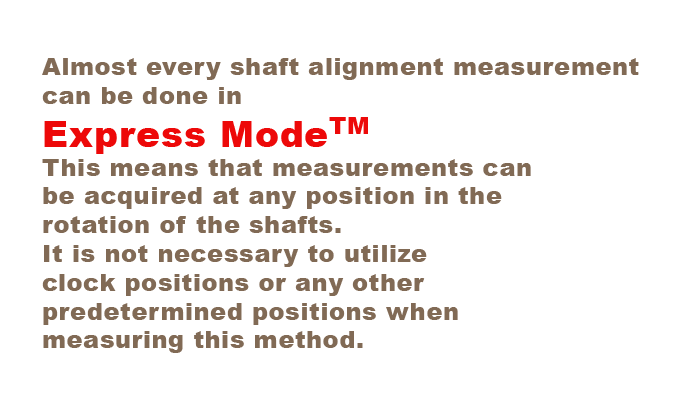

Proper use of any tool is essential to success in achieving your desired goal. Many tools have optional configurations to adapt that tool to your needs. Fixturlaser Precision Alignment Systems are no different. The alignment tools produced by Acoem/Fixturlaser are second to none in ease of use. The Acoem AB design engineers do all they can to provide the end user with an alignment tool that can be

Most people who work on, or around pumps are familiar with the term “cavitation”. It is often used as a catch all phrase for any flow-related vibration on pumps, and is often reported by vibration analysts when:

Pump noise level is high,

Pump vibration is erratic, with lots of “noise” in the spectrum.

But there are a handful of flow-related vibration problems on pumps, and only one of tho

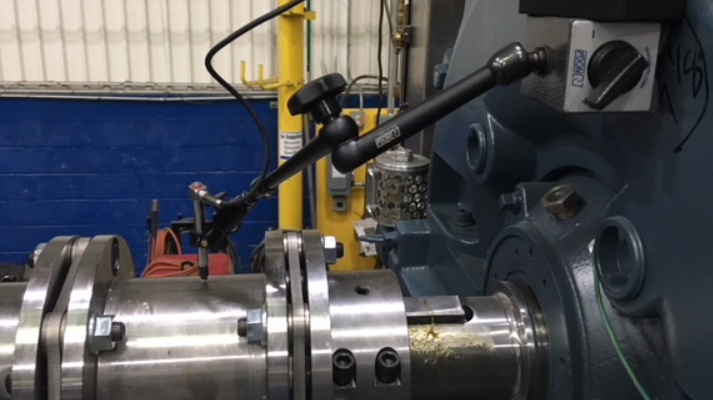

When measuring runout with the Fixturlaser NXA Runout Probe the best practice is to first measure the coupling for non-circular rotation. If runout is detected, the next step is to measure the shaft to determine if the runout is caused by a bent shaft versus an eccentric coupling

Laser Shaft Alignment systems should be properly maintained for optimal performance. Dirty sensors (laser and detector lens) can lead to non-repeatable measurement results. All system components should be stored properly in the carry case to prevent damage to said components.

Even when we are going to perform an alignment on a piece of equipment, it is a good practice to record a pre-alignment measurement to document or maybe explain any possible issues later.

Regardless of whether upkeep specialists are utilizing Rim and Face or Reverse Dial Indicator Sets, or any of the laser shaft arrangement frameworks they are on the whole making progress toward a similar result. Which is to have the rotational shaft centerlines of the driver and driven machine(s) adjusted (collinear) in the vertical and flat planes when the machines are working.

When laser alignment tools are not repeatable, it’s not the laser – IT’S YOU.