Shaft Alignment Frustrations - 3 Common Reasons

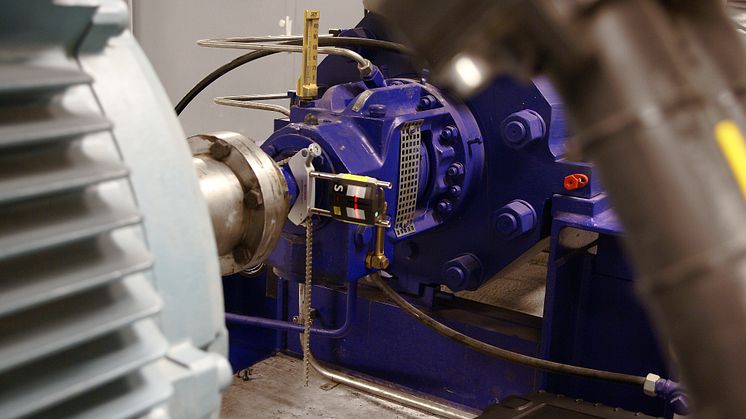

The first most common reason for unpredictable alignment results is looseness of some kind.

The first most common reason for unpredictable alignment results is looseness of some kind.

Most industrial maintenance mechanics who are involved with precision shaft alignment are familiar with the phenomenon of soft foot. Alignment standpoint, soft foot causes: Changes in alignment values, between when the hold down bolts are loose, and when they are tight. Non-repeatability in alignment measurements, especially if the bolts are not tightened in the same order and manner each time.

Most laser alignment tools include a soft foot function. However, in truth these tools haven’t measured ACTUAL soft foot, instead they have measured the EFFECT of soft foot at the shaft or coupling as that is where the laser heads or sensors are mounted. While the EFFECT of soft foot is important, correcting the ACTUAL soft foot will also correct the EFFECT of soft foot.

It’s no joke that many machines operate with high levels of vibration due to soft foot. These same machines often have a decreased life span due to this condition.

There are many things that can affect the precision shaft alignment process, which needs to be checked and eliminated during the Pre-Alignment Steps, such as pipe strain, disintegrating bases, bearing or coupling wear, One of the main issues concerning shaft alignment of rotating equipment is the challenge of soft foot and its detrimental effect on the alignment process.