News -

Pre-cooling for Compressor Dryers

THE CHALLENGE

When producing compressed air, it is of utmost importance that the moisture is removed from the air. If not removed properly the moisture can cause problems with the use of pneumatic tools, cause corrosion, can freeze and damage the piping etc. Due to these facts dryers of different kinds are a standard component in the treatment of compressed air. The dryers function is to remove the moisture from the air. However, the air entering the dryer is in some cases pre-cooled to remove moisture already before entering the dryer. This allows the end customer to use a smaller and more cost-efficient system solution. Pre-coolers should be efficient, compact and not take up too much floor space to create a cost-efficient solution.

THE SOLUTION

The pre-dominant pre-cooler solution on the market today is Shell and Tube type heat exchanger. Shell and Tube Heat Exchangers are a proven design, yet they are known to be bulky and highly inefficient. They take up a lot of floor space due to its long shell.

Airec Compact design has unique advantages as pre-cooler due to its high efficiency, excellent condensing capacity and compact design.

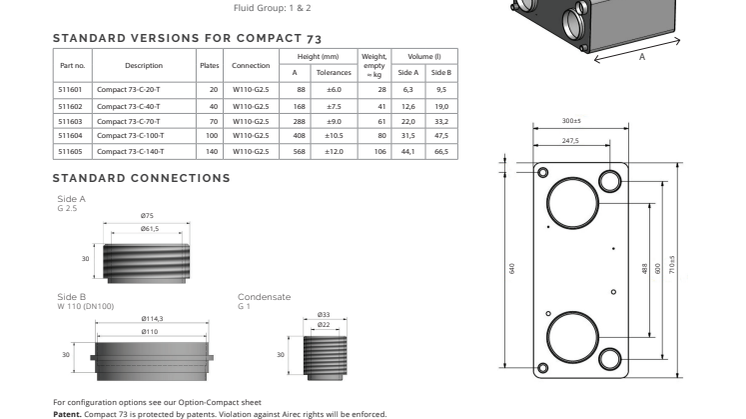

Performance

| Flow rate compressed air |

3 400 Nm3/h |

| Pressure | 7 bar(g) |

| Capacity |

35 kW |

| Condensation | 20 kg/h |

| Condensing pre-cooler |

Compact73-C-40-G |

THE RESULT

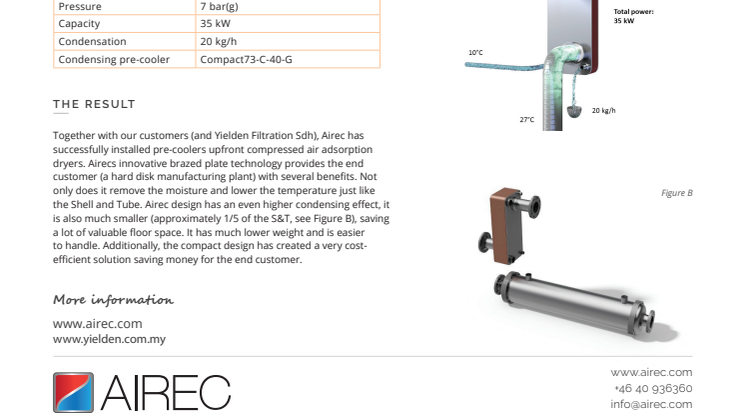

Together with our customers (and Yielden Filtration Sdh), Airec has successfully installed pre-coolers upfront compressed air adsorption dryers. Airecs innovative brazed plate technology provides the end customer (a hard disk manufacturing plant) with several benefits. Not only does it remove the moisture and lower the temperature just like the Shell and Tube. Airec design has an even higher condensing effect, it is also much smaller (approximately 1/5 of the S&T, see figure), saving a lot of valuable floor space. It has much lower weight and is easier to handle. Additionally, the compact design has created a very cost-efficient solution saving money for the end customer.

Topics

- Energy issues