Pressmeddelande -

Schaeffler provides customers with transparency on the CO2e footprint during production and use phase

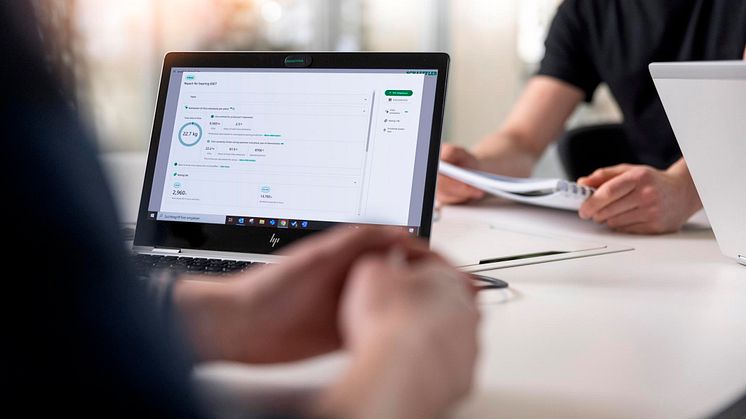

- Since the beginning of the year, Schaeffler has provided its customers with a CO2e emissions calculator, which also takes the use phase of rolling bearing products into account.

- All that is required is the input of load and speed data in the online product catalog “Schaeffler medias”

- Even more precise calculation possible by adjusting further operating parameters for different load cases in real time using “medias EasyCalc”

Arlandastad | March 20, 2025 | To achieve their climate targets, companies require transparency regarding the CO2 emissions created by supplier products. This includes the CO2 emissions that are produced during the manufacturing process and those that arise during subsequent operation. The Motion Technology Company Schaeffler now provides this information for the majority of its rolling bearing product portfolio.

Based on this emission values, customers can make data-based investment decisions, which are in line with their sustainability targets. Schaeffler displays the emissions in so-called carbon dioxide equivalents, abbreviated as “CO2e”, as a metric measure used to compare the emissions of various greenhouse gases based on their global-warming potential (GWP).

Since the beginning of 2025, the calculator in the digital product catalog “Schaeffler medias” has not just offered the option of calculating the production-related CO2e emissions at individual bearing level. It also shows the emissions caused by friction losses in the bearing during the utilization phase. “In this way, we are helping our customer to achieve their climate targets. As a leading global bearing manufacturer, we continually strive to manufacture rolling bearings with even less friction”, says Dr. André Schade, Sustainability Coordinator for Product Development in R&D at Schaeffler Bearings & Industrial Solutions.

“Our customers can now find out quickly and simply how many CO2e emissions are produced by the operation of a rolling bearing in their application – and therefore how the selection of a bearing with optimized friction behavior has an impact on the operating costs in quantitative terms”, explains André Schade.

Relevance for all industrial sectors

Because this information can be found directly in the product catalog, customers who are registered with “Schaeffler medias” can select their desired products as usual. They also have the option of defining the planned application based on several load cases. To receive informative values on CO2e emissions during the use phase, all that is required is the input of load and speed data for the application. This allows for instance a comparison between friction-optimized and standard bearings.

High level of detail in “medias EasyCalc”

Furthermore, customers can delve deeper into this topic on the platform “medias EasyCalc”: The influences of lubrication, operating temperature, and oil flow during application can be included in the calculation.

The platform also features direct links to Schaeffler’s solutions in the fields of mounting (assembly, fitting) and lubrication, as well as a link to a tool, which shows how the production in many sectors can be made more sustainable using Schaeffler products. Of course, it is also possible to find the best possible solutions for all specific applications in direct contact with our experts.

“medias EasyCalc” is available on the internet at the following link:

https://medias-easycalc.com/

Relaterade länkar

Kategorier

Schaeffler Group – We pioneer motion

Schaeffler Group har drivit fram banbrytande uppfinningar och utvecklingar inom området rörelseteknologi i över 75 år. Med innovativa teknologier, produkter och tjänster inom elektrisk mobilitet, CO₂-effektiv drivning, chassilösningar, digitalisering och förnybar energi är företaget en pålitlig partner för att göra rörelse mer effektiv, intelligent och hållbar – under hela livscykeln. Schaeffler beskriver sitt omfattande utbud av produkter och tjänster inom mobilitet med hjälp av åtta produktfamiljer: Från lagerlösningar och alla typer av linjära styrsystem till reparations- och övervakningstjänster. Schaeffler har omkring 120,000 anställda på fler än 250 platser i 55 länder och är ett av världens största familjeägda företag och ett av Tysklands mest innovativa företag.