Crew change vessel adapted to suit the market

ESVAGT’s next crew change vessel will be trimmed to meet the need for savings.

ESVAGT’s next crew change vessel will be trimmed to meet the need for savings.

Many fine suggestions have already optimised working practices in several areas.

Every year, ESVAGT and DONG hold a combined exercise to ensure that their oil spill contingency plans function as intended.

The ’Esvagt Aurora’ assisted in the transfer of the first oil produced in the Barents Sea.

The rescue operation in the Barents Sea brings ESVAGT the safety award from ENI.

A systematic approach will ensure the optimal level of FRB sailing competence for all vessel crews.

At the age of 57, Viggo Hvidberg now has a student ID card. “I need to improve and advance!”

ESVAGT wants to become better at analysing incidents and implements learnings from them.

The ’Esvagt Omega’ has taken part in 13 rescue missions and saved the lives of 48 people. Now it is time for her to retire.

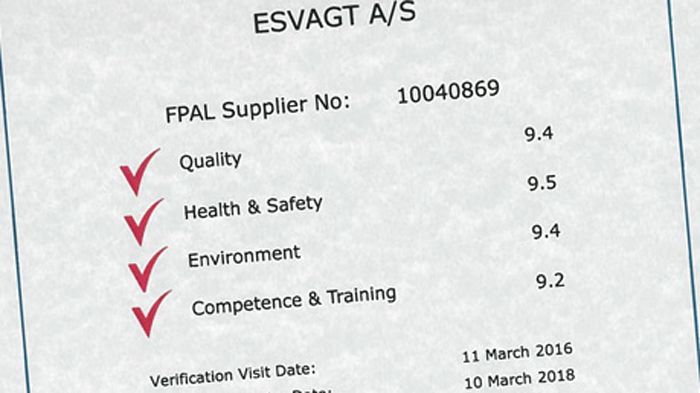

ESVAGT was assessed by FPAL on 10 and 11 March 2016.

Revenue for the ESVAGT Group in 2015 was DKK 1,002.8m against DKK 946.5m in 2014. EBITDA for the year is DKK 435m compared to DKK 417m in 2014.

Young people with a chequered past can turn their lives around and look forward to a promising future with Headspace. ESVAGT offers support.

Comments rising from the Employee Engagement Survey.

ESVAGT employees retain their motivation and well being.

ESVAGT’s crew change vessels will get a fixed base midway between logistics, the office and the workshops.

ESVAGT is building a new Service Operation Vessel (SOV) for MHI Vestas Offshore Wind to service the offshore wind farm off the Belgian coast.

The Service Operation Vessel (SOV) for the offshore wind farm, the Dudgeon Wind Farm, has left the Gdansk shipyard. It will now be fitted out at Havyard in Norway.

The price situation in offshore markets demands an increased focus on costs. Operation ’Fit for Fight’ will ensure that ESVAGT continues to be a well-trimmed organisation.

The classic maritime tip revived to reduce occurrence of minor injuries.

With the refurbishment of the ’Esvagt Preserver’, five of ESVAGT’s eight group 3 vessels have received an extensive life-extension refit at the shipyard in Søby.