Press release -

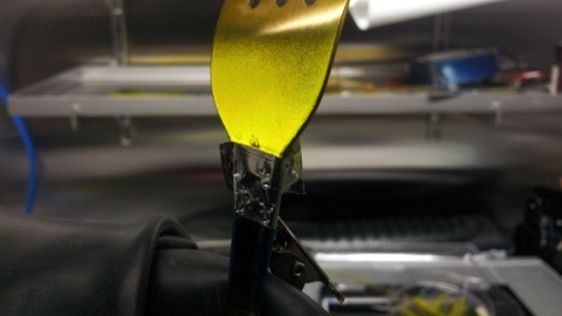

Light-emitting fork made with sprayed LEC technology

Light-emitting electrochemical cells, LEC, is a newly invented lighting technology. In his thesis, physicist Amir Asadpoordarvish, Umeå University, shows how a LEC can be produced through spraying three layers of ink on a substrate and emit light by the current from an ordinary battery. LEC components can be sprayed onto complicated surfaces, for example to make a light-emitting fork.

“In a recent study we also showed that it is possible to spray the LEC structure directly onto conventional, cheap copy paper,” says Amir Asadpoordarvish. “Such a paper LEC exhibits an even light-emitting capacity even during repeated bending and flexing.”

Artificial lighting has brought great advantages to mankind. In recent years enormous progress has been made possible through commercialization of energy-efficient light-emitting diodes, LEDs, and high contrast computer screens based on organic LEDs. However, organic LEDs require an expensive and complicated production process. It is likely that the next big breakthrough in lighting technology will be the discovery of cheap and “green” techniques, produced in a cost and material efficient way using safe and easily accessible raw materials, at the same time being flexible, durable and light-weight. Light-emitting electrochemical cells, LECs, could be what make the vision become reality, Amir Asadpoordarvish argues in his thesis.

A LEC is based on an active material placed between a cathode and an anode. In his thesis, Amir Asadpoordarvish shows how the research group of professor Ludvig Edman, which he is a part of, succeeded in making functional LECs by spraying three layers of ink, and thus creating anode, active material and cathode, on top of a substrate. Such components can emit light using only currency from an ordinary battery. In the same study they showed that spray-sintered LECs are highly efficient and can have both multi-coloured and patterned light emission.

“They can be produced directly onto complicated surfaces. One extraordinary example of this is the light-emitting fork we were able to produce,” says Amir Asadpoordarvish.

The research group also solved the problem of protecting the light-emitting cells from surrounding air by encapsulating it with a mix of glass and epoxy plastic. This resulted in a long-lasting LEC with a lifetime of 5 600 hours, as compared with the 1 000 hours an ordinary light bulb has.

The thesis is published digitally

For more information, please contact:

Amir Asadpoordarvish, Department of Physics, Umeå University

Phone:+46 70 4839206

Email:amir.asadpoordarvish@umu.se

High resolution photo light-emitting fork

High resolution photo light-emitting paper

About the dissertation defence

Friday 22 May Amir Asadpoordarvish, Department of Physics, Umeå University, defends his thesis entitled “Functional and Flexible Light-Emitting Electrochemical Cells” (Swedish title: “Funktionella och flexibla ljusemitterande elektrokemiska celler”).

Faculty opponent is professor Jun Gao, Department of Physics, Engineering and Astronomy, Queen’s University, Ontario, Canada. The defence will take place at 10:00 in room N300, the Natural Sciences Building, Umeå University.

Topics

Categories

Umeå University

Umeå University is one of Sweden's largest institutions of higher learning with over 32,000 students and 4,200 employees. We have a well-established international research profile and a broad range of study options. Our campus constitutes an inspiring environment that encourages interdisciplinary meetings - between students, researchers, teachers and external stakeholders. Through collaboration with other members of society, we contribute to the development and strengthen the quality of our research and education.