Blog post -

AGVs in Logistics

Although AGVs (Automatic Guided Vehicles) are currently mainly used in manufacturing related applications, the market for AGVs specialized in logistics is expected to witness significant growth in the coming years. The trend of distribution centers - such as those of convenience stores and online shopping establishments - handling large varieties of different products in small quantities remains strong while labor costs are rising. At the same time it is becoming increasingly difficult to staff warehouses. These factors combine to create an increase in demand for AGVs.

AGVs used in distribution warehouses face different requirements than their manufacturing facility counterparts and need to be relatively small and silent as well as capable of unguided operation. As they are designed to substitute human labor, they carry loads of a few tens of kilograms as opposed to AGVs in the manufacturing industry expected to handle loads of several tons. Furthermore, they face higher constraints on acceptable noise levels due to their different operating environment. In addition, AGVs operating inside warehouses need to be flexible and capable of moving around freely, without relying on magnet tape attached to the floor, using laser radars and image recognition technology to detect and avoid obstacles.

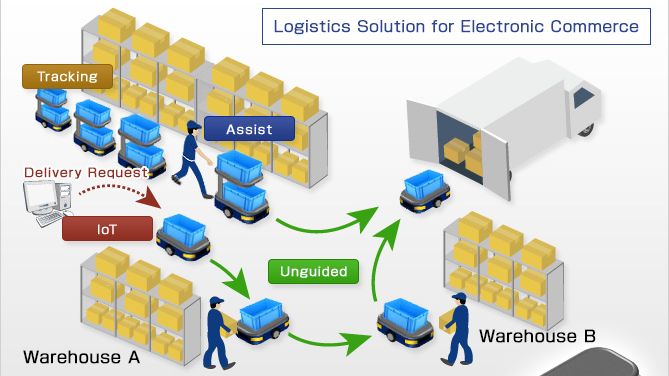

In response to these needs, the Nidc group is developing a series of AGVs equipped with a number of advanced features such as the ability to track and follow other AGVs to move in convoys without physically being connected, an assist mode allowing the AGVs to work in tandem with humans, and the ability to predict and prevent breakdowns and suggest optimal operation settings by using IoT to collect and analyze position data, traveling data and vibration and noise pattern related data. Due to their low-noise properties, these new AGVs are also suited for operation in environments such as health facilities and museums as well, making the potential demand for them even higher.

The Nidec group also supplies individual components and combined units, such as drive units, that integrate brushless DC motors, high precision reduction gears, sensors and other components. Our brushless DC motors and high precision reduction gears, in particular, are backed up by of our leading-edge technology and proven track record.