Press release -

First Car Using Nidec’s E-Axle Traction Motor System Unveiled

Kyoto, Japan: The new electric car brand Aion S recently unveiled at Auto Guangzhou 2018 by GAC NE, GAC MOTOR’s new energy vehicle arm, will be the first line of cars to adopt Nidec’s fully integrated traction motor system (E-Axle). The super e-car with a driving mileage of over 500 kilometers is slated to hit the market in 2019.

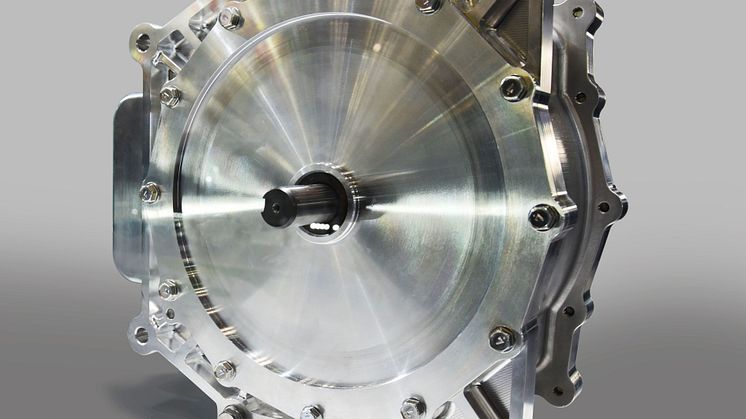

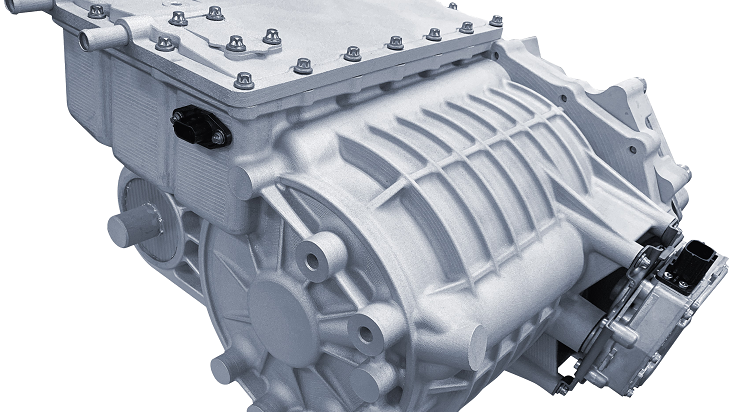

Nidec’s automotive traction motor system was first revealed in September 2017 and the company later went on to announce the successful development of a refined design that fully integrates the reduction gearbox and inverter. Weighing in at only 83 kg1, the compact and light-weight system achieves a power output of 150 kW and a maximum torque output of 3,900 Nm. It is a modified 87 kg version of this new integrated system that will power the Aion S. Mass production will start in 2019 in Nidec’s new dedicated 66,000 m2 factory in the Pinghu Economic Development Zone near Shanghai.

Although the traction motor system will be launched in the Chinese market first, Nidec plans to make the product available to European automobile manufacturers as well in the near future. "Carmakers from all around the world have contacted us since we announced our E-Axle and we are currently considering building another dedicated factory in Poland,” said Dr. Kazuya Hayafune, Chief Engineer and Deputy Executive General Manager of the company’s automotive division.

Nidec started out as a manufacturer of small electric motors for appliances and other machines in 1973 in Kyoto, Japan. Initially a company of only four engineers, it has now grown into a global company group employing over 100,000 people in more than 40 countries across the world. Major products designed and manufactured by Nidec include HDD spindle motors, of which the company has captured 85% of the global market share, and electric power steering motors for automobiles. To date, the company has acquired 60 different businesses, and many of its recent acquisitions, such as that of Honda Elesys (now Nidec Elesys) in 2014, have been focused on strengthening its capabilities in the automotive segment. Nidec also recently launched a joint venture with French Groupe PSA to develop, manufacture and sell a separate lineup of automotive electric traction motors.

_______________________________________________________________________________

1A 2.5 L internal combustion engine with an equivalent power output would weigh around 160 kg.

Topics

Categories

Nidec was established in Kyoto, Japan in 1973 by its Chairman and CEO Shigenobu Nagamori. In 1979, Nidec became the first company in the world to successfully commercialize a direct drive spindle motor for HDDs based on a brushless DC motor. Since then, the company has grown into a world-leading comprehensive motor manufacturer encompassing more than 300 subsidiaries employing over 100,000 people throughout the world and with annual sales exceeding $13B. Nidec's motors, drives, generators and related products are found in a diverse range of applications including computers, smartphones, home appliances, automobiles, manufacturing plants, robots and more.