Press release -

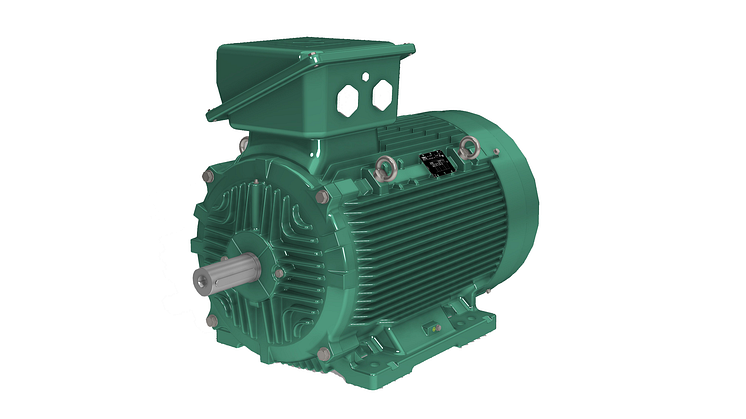

IMfinity CILS: New cast iron induction motors with IE4 efficiency from Nidec Leroy-Somer

The new CILS series in the IMfinity 3-phase induction range from Nidec Leroy-Somer benefits from an up-to-date cast iron mechanical design, optimized and adapted for standard application requirements. This innovative design focuses on reduced energy consumption of machines while maintaining maximum level of robustness, performance and flexibility. Thanks to its Super Premium IE4 energy efficiency class, the CILS series is fully compliant with European regulations on efficiency, the latest requirements of which have come into force on 1st July 2023.

Covering most of the industry needs, the proven multi-purpose IMfinity® induction motors provide extended features for a simple integration worldwide, in standard and safety environments.

The Nidec Leroy-Somer iconic range is enriched today with the CILS series of cast iron motors, mainly oriented on fan, pump and compressor applications, from 75 to 200 kW. Developed from the electrical core of the IMfinity® range, the CILS offers reliability, power and adaptability of a renowned manufacturer.

Reduce energy bill and carbon footprint

In accordance with the ecodesign requirement of the EU 2009/125/EC directive and with the Commission Regulation UE 2019/1781 on induction electric motors, the IMfinity® CILS series ensure energy consumption reduction thanks to its IE4 Super Premium efficiency level.

Offering an excellent cost-benefit ratio, CILS motors greatly contribute to sustainability, lower carbon footprint and energy bill savings.

Their standardized IEC mechanics design allows easy integration in an existing application or equipment, thus improving the energy performance of the driven machine.

Priority to flexibility through an adaptative design

The IMfinity® CILS motor series has been ergonomically designed to make its adoption as simple and convenient as possible for the users.

It includes many arrangements to facilitate its adaptation and integration while improving lead times and availability.

For instance, the CILS motor is fitted with a multi-position terminal box designed to provide a greater flexibility of installation: pre-drilled in factory, it has an internal earth terminal. Added to that, no grounding braid is required for HF continuity, bringing simplicity, reliability and robustness for variable speed applications.

Reduced stock and increased capabilities

In addition to the versatile new terminal box, many other elements have been developed to reduce the number of references and related level of stock to manage while maximizing late customization capabilities and decreasing lead times.

Saving time and effort, these technical choices result particularly in:

- Only one stator diameter per frame size, to simplify and mutualize the management of mechanical options

- A B3 feet-mounted position easily convertible into aB35 configuration (feet and flange)

- A fan cover design adapted for a drip cover integration in case of operation in vertical position, shaft end facing down

- A shaft with captive keyway to facilitate assembly in vertical shaft mounting.

Enhance robustness of an advanced reliable design

The IMfinity® CILS has been developed to further improve reliability and lifetime of the motor while facilitating its maintenance and serviceability. Designed for a reinforced protection, it includes components ensuring high resistance, such as:

- Drive-end shields with optimized fins to improve thermal exchange as well as bearing lifetime

- AEGIS ring (as an option) integrated in the drive-end shield to protect the bearings for use in variable speed

- Shaft seal by rolling to ensure maximum tightness on both sides (DE and NDE)

- Housing designed with an internal channel to route sensor cables inside the motor, thus providing the highest protection

- Profiled rear fins to prevent water retention

- Fan cover with bayonet-like fixings to enable easier mounting and maintenance

- Drive-end bearings axially locked for adaptation to the most demanding applications, which is a particularly useful solution for pumping

By meeting the most diverse requirements of main industrial sectors, the CILS motor is a key component for manufacturers looking for a customizable, economical and sustainable solution to drive their machines.

Further information and related documentation can be found on:

FIN

About ACIM

Nidec Appliance, Commercial and Industrial Motors (ACIM) is a Nidec Corporation business unit that holds three Platforms: Global Appliance (GA), U.S Motors (USM), and Commercial & Industrial (C&I). With over 20,000 employees and more than 30 manufacturing sites in 25 countries, it is the largest division in terms of sales in side Nidec Group. ACIM has a vast portfolio that covers compressors, condensing units, and motors for home and commercial appliances, as well as motors and electronic drives for commercial, residential, industrial, and utilities applications. This comprehensive set of solutions is characterized by high standards of quality and energy efficiency, delivering innovation at the service of sustainability.

About Leroy-Somer

Leroy-Somer is one of the world’s leading manufacturers of electric motors and associated electronics, as well as the world leader in industrial alternators. The company which was established in 1919 in France and employs around 6200 people worldwide has become part of the Nidec Group in 2017.

Topics

Categories

Nidec was established in Kyoto, Japan in 1973 by its Chairman Shigenobu Nagamori. In 1979, Nidec became the first company in the world to successfully commercialize a direct drive spindle motor for HDDs based on a brushless DC motor. Since then, the company has grown into a world-leading comprehensive motor manufacturer encompassing more than 300 subsidiaries employing over 100,000 people throughout the world and with annual sales exceeding $13B. Nidec's motors, drives, generators and related products are found in a diverse range of applications including computers, smartphones, home appliances, automobiles, manufacturing plants, robots and more.