Press release -

New CamGT Air Inlet Filter Line Boosts Power, Uptime and Profits

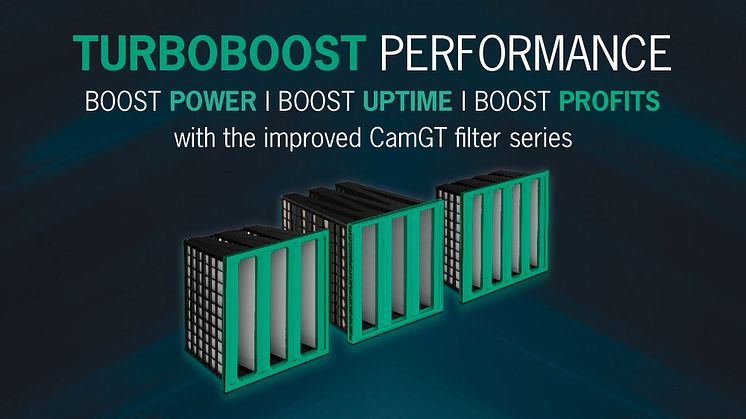

Camfil Power Systems, the industry expert in clean air solutions for turbomachinery, has released its latest generation of the CamGT product line featuring hydrophobic, low, and stable pressure drop air inlet filters designed to boost turbomachinery performance.

CamGT filters are engineered to excel in extreme environments where turbomachinery is threatened by high humidity, salt-laden air, heavy pollution, or fine particulates. They are designed for EPA efficiency to Boost Power by virtually eliminating degradation while maintaining a low and stable pressure drop, to Boost Uptime by eliminating maintenance requirements for filters and engine parts, and to Boost Profits by significantly reducing operating expenses.

“The new features will increase equipment availability, reduce corrosion risk, and improve fuel consumption and carbon footprints,” said Product Manager, Sophie Belanger.

New features:

- Patented pleating technology permits a more open face geometry and the patented aerodynamic grid redirects the exiting air, reducing pressure drop

- Patented drainage vane design improves drainage capabilities

- Hydrophobic media and patented double sealed construction eliminate the risk of dissolved contaminants passing through the filters, thus eliminating corrosion risks, as well as reducing fouling

- Original vertical pleat with open hot melt ensures drainage for a low and stable operating pressure drop

- Rigid one-piece front frame and supporting grid ensure wet burst pressure over 6 000 Pa

The new generation includes three models. At an E10[1] efficiency rating, the Improved CamGT 4V-300 has a reduced initial pressure drop, now at 200 Pa. The New CamGT 3V-440 features outstanding pressure drop performance for its depth range, initially at 155 Pa. The Flagship CamGT 3V-600 has a current global installed base of more than 20,000 filters, some of which have been safely operating for over 40,000 hours, and is still the market leader with an initial pressure drop at 135 Pa.

CamGT filters are offered from ISO ePM1 75% (F7[2]) to E12 efficiency and have been tested to the latest industry standards: efficiency, burst strength, and water repellency per ISO 16890:2016, EN1822:2019, and the upcoming standards ISO29461-3 and ISO 29461-7.

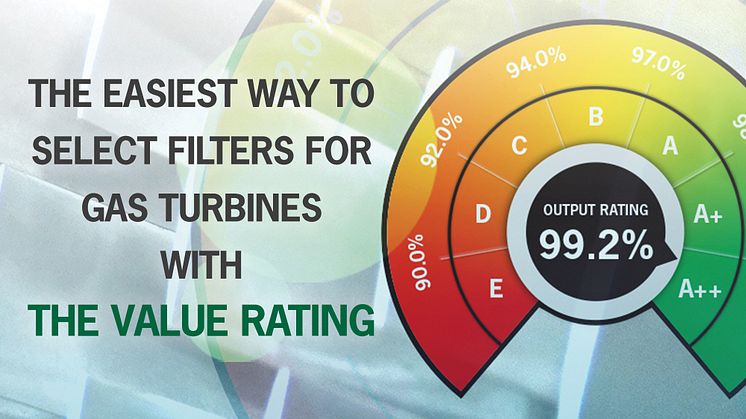

The Value Rating, the newest filter classification system, shows that at an E12 efficiency rating, a Typical E12 filter has a 98.6% Output Rating (expected gas turbine power output), the CamGT 3V-600 has 99.2%, the CamGT 3V-440 has 99.1%, and the CamGT 4V-300 has 98.9%. This filter comparison shows that even a small increase could significantly improve profitability for the gas turbine operator. To quantify the impact on your gas turbine, visit The Value Rating page: www.TheValueRating.com

To learn more about the boosting the performance of your turbomachinery with CamGT filters, please contact your local Camfil representative and visit www.camfil.com/TurboBoost .

[1] Tested at 4250m3/hr per En1822:2019

[2] Per EN779: 2012

About Camfil Power Systems:

Camfil Power Systems specializes in air inlet and acoustical systems for turbomachinery, including gas turbines, generators, industrial air compressors, and diesel engines.

Our engineering experts continuously strive to protect this high-value equipment by designing the best filtration and acoustical solutions to meet the priorities and requirements of original equipment manufacturers (OEMs), engineering procurement construction companies (EPCs), operators, and end users. They can be assured that their equipment will operate in the most profitable way, with maximum availability and reliability.

Camfil Power Systems is part of the Camfil Group, a world leader in the development and production of air filters and clean air solutions, with 30 manufacturing sites, six R&D centers, and local sales offices in 30 countries. For information or to contact a Camfil Power Systems representative, use the Contact Locator or email TheValueRating@camfil.com.

Topics

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. We firmly believe that the best solutions for our customers are the best solutions for our planet, too. That’s why every step of the way – from design to delivery and across the product life cycle – we consider the impact of what we do on people and on the world around us. Through a fresh approach to problem-solving, innovative design, precise process control and a strong customer focus we aim to conserve more, use less and find better ways – so we can all breathe easier.

The Camfil Group is headquartered in Stockholm, Sweden, and has 30 manufacturing sites, six R&D centres, local sales offices in 30 countries, and 4,800 employees and growing. We proudly serve and support customers in a wide variety of industries and in communities across the world. To discover how Camfil can help you to protect people, processes and the environment, visit us at www.camfil.com.