Press release -

The Value Rating: Easiest way to select the best filters for gas turbines

The Value Rating: The Easiest Way to Select the Best Filters for Gas Turbines

Camfil Power Systems, the leader in providing clean air solutions for turbomachinery, introduces The Value Rating classification system to simplify the filter selection process for gas turbine users in the Power Generation and Oil & Gas industries, by helping them easily evaluate the efficiency and quality of primary air inlet filters.

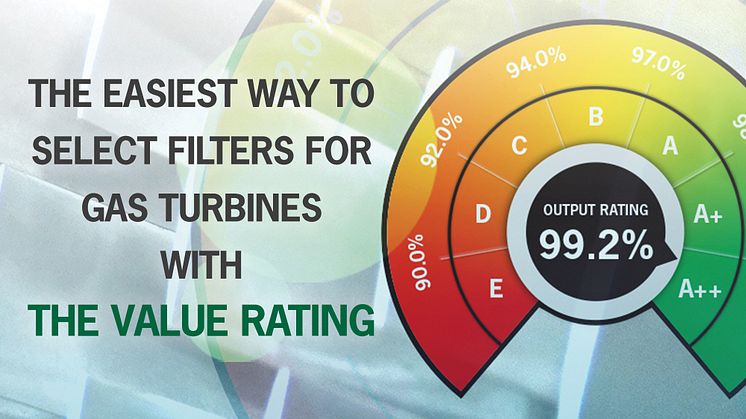

The Value Rating of a filter is a projection of the impact a final filter will have on a gas turbine’s performance in terms of power output, fuel consumption, and carbon emissions. A filter’s Value Rating can be calculated using a new online calculator, and requires four simple inputs that can be pulled from a filter’s test report: filter efficiency, airflow, initial pressure drop, and filter pressure drop after 250 grams of dust loading. It is based on a standardized environment and the latest published data from gas turbine manufacturers to allow for a quick performance comparison. With this data, operators can quickly compare the impact of different filters and make the best selection for their gas turbine(s).

“With the ability to quickly find the value rating of any filter, it has never been easier for turbine operators to keep track of how filtration solutions impact engine performance,” said Sophie Belanger, Global Product Manager at Camfil Power Systems.

Example: The Value Rating Label

Output Rating: 98.8%

The Output Rating value shows the impact that the filter has on power output at full load, and is based on the combined impact of pressure drop and fouling (cleanliness of the engine). The dial ranges from 0% to 100%, with a letter-grade classification from E to A++ to represent the percentage values. The higher the grade, the more power the engine will produce when protected by the filter.

A typical engine rated at 100MW and equipped with a CamGT 3V-600 E10 would output a yearly average of 98.8 MW, losing 1.2 MW to filter-related losses. This filter is classified as a A+-grade filter.

Fuel Penalty: 0.6% MJ/MWh

The Fuel Penalty represents the average additional fuel consumption of a gas turbine in comparison to a perfectly clean engine at start-up.

An additional 0.6% fuel is necessary to compensate for the power loss imposed by the CamGT 3V-600 E10 filter. It is important to note the absence of an air filter would impose a far higher fuel penalty.

CO2 Savings: 16 900 tonnes CO2 / TWh*

The CO2 Savings indicates how much CO2 can be saved with a filter solution when comparing to a low-grade M6 filter. By choosing a higher quality filter, the power output is higher and the fuel penalty is lower, ultimately emitting less CO2. CO2 savings are critical to protect the environment while improving your bottom line by lowering the imposed carbon tax.

The CamGT 3V-600 E10 filter will enable the turbine to produce 16 900 fewer tonnes of CO2 per TWh than a standard M6 filter.

* A 125MW gas turbine operating 8,000 hr / year will generate 1 TWh./ year

For more information and to try the calculators, visit www.TheValueRating.com.

About Camfil Power Systems:

Camfil Power Systems specializes in air inlet and acoustical systems for turbomachinery, including gas turbines, generators, industrial air compressors, and diesel engines.

Our engineering experts continuously strive to protect this high-value equipment by designing the best filtration and acoustical solutions to meet the priorities and requirements of original equipment manufacturers (OEMs), engineering procurement construction companies (EPCs), operators, and end users. They can be assured that their equipment will operate in the most profitable way, with maximum availability and reliability.

Camfil Power Systems is part of the Camfil Group, a world leader in the development and production of air filters and clean air solutions, with 30 manufacturing sites, six R&D centers, and local sales offices in 30 countries. For information or to contact a Camfil Power Systems representative, use the Contact Locator or email TheValueRating@camfil.com.

Related links

Topics

Categories

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment. We firmly believe that the best solutions for our customers are the best solutions for our planet, too. That’s why every step of the way – from design to delivery and across the product life cycle – we consider the impact of what we do on people and on the world around us. Through a fresh approach to problem-solving, innovative design, precise process control and a strong customer focus we aim to conserve more, use less and find better ways – so we can all breathe easier.

The Camfil Group is headquartered in Stockholm, Sweden, and has 30 manufacturing sites, six R&D centres, local sales offices in 30 countries, and 4,800 employees and growing. We proudly serve and support customers in a wide variety of industries and in communities across the world. To discover how Camfil can help you to protect people, processes and the environment, visit us at www.camfil.com.