Press release -

New crew change vessel is a ‘handsome compromise’

ESVAGT’s requirements and wish list for the new crew change vessel looked like a ’Mission Impossible’- but was not.

”We would like a larger vessel that sails faster but still has the same fuel consumption level as today”.

It was far from ’business as usual’ when ESVAGT approached Havyard with a wish list for a new crew change vessel.

“Faster speed and a larger vessel are doable – greater speed in a larger vessel without increasing fuel consumption is something quite different,” says Havyard’s senior designer for hydrodynamics, Kristian Steinsvik:

“The starting point for the whole business case was to keep to the fuel consumption level of ESVAGT’s current crew change vessel, the “Esvagt Alpha”,” he says:

”The new vessel needed to be wider to give more space – three metres more than the “Esvagt Alpha”. Increasing width is the worst parameter with regard to fuel consumption. Combine that with the requirement to go faster and you almost have a ’Mission Impossible’,” he says.

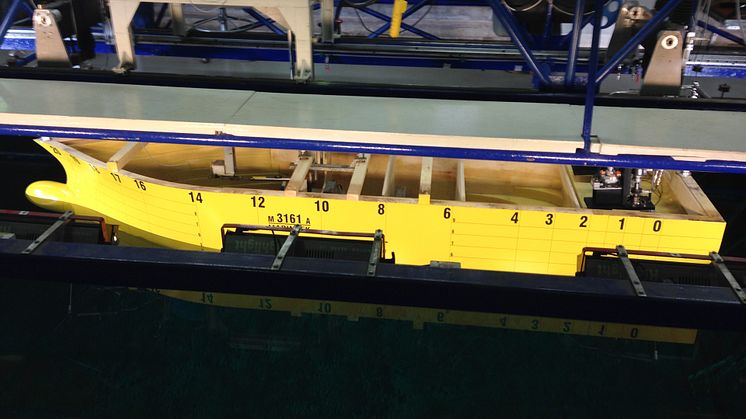

Tested for the North Sea

Havyard used the maximum of its own skills and then collaborated with a number of external specialists to progress. Havyard used, amongst others, the Norwegian marine technical research institute, Marintek, which is part of Sintef; Scandinavia’s largest independent research organisation. They also worked with leading specialists in advanced stream analysts in water, oil and air and used an automated CAD design that was tailor made to optimise for set conditions and design parameters:

“We went direct to the software developers for the simple reason that the analysis system we needed is not an established industry standard and we wanted the details to be done out by specialists. That demanded that we set the correct limits and chose the right parameters for optimisation,” says Kristian Steinsvik.

The goal was to find a method that could calculate the consequences of given design optimisations based on Havyards comprehensive database of hull geometry. Havyard has been compiling a database of boat types in the North Sea since 2010. The hulls are tested in a comprehensive development programme, where the boat’s characteristics and working conditions in the North Sea are combined in a detailed matrix:

“We developed an automated geometry model for the optimisation of hulls. We have calculated some 100 variations on the hull alone. When we vary the height of the bulb by 2 centimetres, this change will occur – if we vary it by 4 centimetres, then this will be the result. All aspects of the design have been calculated,” says Kristian Steinsvik.

From Hummer to Prius!

Results have not been unforthcoming. The vessel that has now been designed has been optimised to the extreme. This process has also changed Havyard’s approach to this type of task. Gisle Vinjevoll Thrane, Sales Manager for Havyard, believes that this method and approach are here to stay:

”The conditions under which we have designed ESVAGT’s new crew change vessel are definitely not industry standard. It has been an experimental process – and a process that has been highly educational,” he says:

“It has been an extreme challenge. ESVAGT’s demands appeared at first glance to be way below what we thought were possible. They wanted a Hummer with the fuel consumption of a Toyota Prius! But then we looked at the task more closely and started to solve the challenge. That part of the process has been exciting. When we can do business and at the same time learn from a demanding and exciting customer, it drives us forwards,” says Gisle Vinjevoll Thrane.

He feels that the experience will influence Havyard from now on:

“Operators, class authorities and other authorities are all working in the same direction that ESVAGT has done here. The trend is to increase emissions control and to require more documentation of fuel consumption. The method and approach we have used here will therefore definitely become part of the way we work in the future,” says Gisle Vinjevoll Thrane.

And the crew change vessel itself?

“It is without a doubt the best possible compromise within the scope that was defined – and a handsome compromise at that,” he says.

Topics

Categories

ESVAGT is a dedicated provider of safety and support at sea, founded on an experienced and well-trained offshore crew and unmatched rescue capabilities.

We support the offshore Oil & Gas industries with a wide range of specialized services: Standby, Emergency Response and Resque Vessels (ERRV), Oil spill response, Firefighting, Tanker assists, Rig moves, Supply services and Interfield transfer of cargo and personnel.

In 2010, ESVAGT brought the dedicated offshore wind Service Operation Vessels (SOV) to the market. The SOVs provide accommodation for up to 40 technicians, storage for small turbine parts and a workshop, plus personnel and equipment transfer capabilities by either Walk-to-Work gangway system or Safe Transfer Boats.

ESVAGT was founded in 1981 and has a fleet of more than 40 vessels and more than 900 employees on- and offshore.