Press release -

Shut-off reliability and system availability: Selective Power Distribution with Device Protection Switches

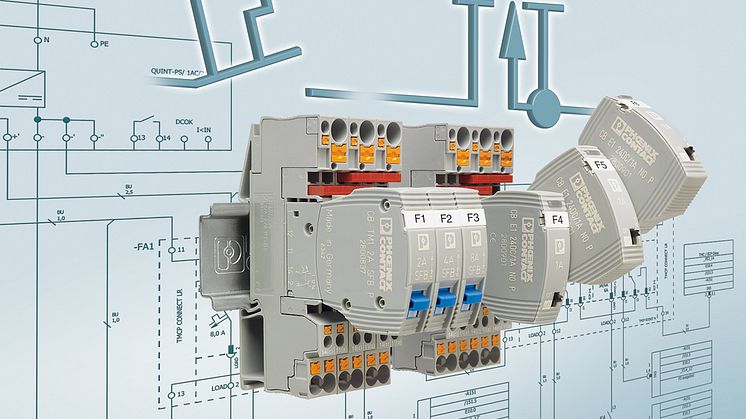

Phoenix Contact's new device protection switches increase shut-off reliability and system availability while saving space in the control cabinet.

To combine availability and efficiency, the right power distribution solution must be chosen early on during the planning stage. The standard supply voltage is 24 V DC, and power is usually subsequently distributed across several load circuits.

Device protection switches must meet two basic requirements: Easy installation and reliable, selective shut-off of individual load circuits in the event of a fault. These core prerequisites dictate how the device protection switches are designed and electrically engineered.

Circuit breakers or device protection switches

Device protection switches and circuit breakers are often considered the same, but their functions are very different. According to standard DIN EN 60898-1, circuit breakers are intended for "household installations and similar applications." They are primarily used for protecting cables. Device protection switches are mainly for protecting against short circuits and overloads, while also offering cable protection, as described in standard DIN EN 60934.

Basic installation is simple. Supply voltage is sent from a DC power supply to a distributor through a large cross section. The distributor then distributes the power to various load circuits that have a smaller cross section and are adjusted to the devices to be supplied (Figure 1). Since the load circuits must be configured in different ways, device protection switches must be as modular as possible in their design. The housing concept must allow for connection of protective switches with different rated currents and, if necessary, different tripping characteristics. To ensure easy installation, a device protection switch should have two parts: a base element and the switch itself. This way, the base elements can be installed first, depending on the number of power circuits. The nominal ratings of the individual load circuits are then defined by selecting the appropriate product type and simply plugging the product into the corresponding base element.

After this step, the different plugs may not be swapped during installation (e.g., in the event of an overload or during maintenance). This is because the individual power circuits are often configured in an application-specific way with different cable cross sections and connected end devices. A practical housing concept should allow for coding between the base component and the plug. The switch is held securely in place, which also ensures flawless operation (Figure 2).

Bridging concepts instead of wire jumpers

Another requirement has to do with the installation base element. When power is distributed, it is usually sent over a cable from the power supply to a distributor or the device protection switches. Cross-switching from the central infeed point to the individual protective switches takes place on the input side of the device protection switch. This configuration can be wired by hand using wire jumpers. However, hand-wiring this cross-connection is time-consuming and tedious. It is also expensive, and these costs can be avoided with intelligent bridging concepts.

The Circuit Breaker product line from Phoenix Contact allows for easy cross-connection thanks to compatibility with the Clipline complete terminal block system, which features a comprehensive range of accessories. On the input side, standardized bridges ensure fast and flawless installation (Figure 3). Bridge shafts are also provided for the integrated signaling contacts, which allow the user to signal the switching status of individual device protection switches or a group of device protection switches. Quick connection technology (push-in technology) is used throughout and also saves installation time.

Reliable selective shut-off

Even though switches are usually installed only once, ease of installation is a key product requirement. During use, the electrical characteristics of a device protection switch are what count the most. The most important characteristic during use in an application is shut-off capacity. The primary task of a device protection switch is to selectively shut off a circuit containing a defective device. Selective shut-off means that the defective load is shut off without impairing the other end devices connected to the power supply. The load can only be shut off if the shut-off conditions have been met.

If there is a short circuit in a device, the current sent from the power supply through the device protection switch must be strong enough to trip the switch. With thermomagnetic protective switches, the required current is often 8 to 13 times the specified rated current. The switch is tripped in this range; a more precise value cannot be specified for reasons of physics. For example, a 2 A protective switch would require 13 x 2 A = 16 A of current to trip reliably. The maximum amount of current the power supply can provide depends on the power supply itself and the total resistance of the circuit.

The cable plays an important role in determining resistance. The greater its length and the smaller its diameter, the greater its copper resistance will be. This resistance significantly limits the maximum length of the cable from the power supply to the loads.

One might assume that these limits on cable length are never reached in practice. But this is incorrect, since the length range for reliable tripping is often only a few meters if the cable has a small diameter. As a result, it is safe to assume that switches in many installations with a 24 V DC power supply do not trip reliably.

Remote control capability

The answer lies in the type of power supply used as well as the characteristic curve and technology of the device protection switch. Electronic device protection switches provide the necessary protection. They usually have an active current limitation and trip within a few milliseconds of a fault. Most importantly, they trip just above the rated current. The electronic versions in the Circuit Breaker product line can also be controlled remotely. In this way, when the user notices that the device has been shut off, the device can be switched on again by remote control, for example to determine whether the shut-off was simply caused by a temporary problem.

If an electronic device protection switch is out of the question, then a less expensive thermomagnetic switch can be used. In this case, maximum cable lengths can only be achieved through precise coordination of the power supply and the characteristic curve of the thermomagnetic protective switch. The Circuit Breaker line from Phoenix Contact includes a thermomagnetic device protection switch with a specially designed characteristic curve that allows for significantly longer cables when used in conjunction with Quint power supplies (Figure 4).

Summary

Device protection switches must meet two basic requirements. First, they must be modular in design and easy to install. This minimizes installation time and increases flexibility of application. At the same time, switches must be available in electronic as well as thermomagnetic versions with different tripping characteristics to ensure the best value for money in any application. The goal is always reliable shut-off in the event of a fault, leading to increased system availability.

Topics

Categories

Phoenix Contact, founded over 80 years ago, is a leading manufacturer of electric connection and industrial automation technology. 11,000 employees, 47 own sales companies and 30 sales partner worldwide ensure customer proximity.

Our work is dedicated to the creation of progress with inspiring, innovative solutions and to a trusting partnership towards our customers and partners with common benefits.