Pressemitteilung -

Robot processing cell closes automation gap: Fettling cast iron parts without reworking

GF Casting Solutions GmbH in Leipzig manufactures heavy but flexible structural parts made of cast iron for agricultural and forestry machinery and construction machinery as well as for renewable energy systems. A robot-based system from FILL with mould nest-specific programme variants enables GF Casting Solutions to fettle smaller iron castings fully automatically, thus closing an automation gap.

Cast iron is the material of choice for highly stressed components for the engines or drivetrains of heavy vehicles. GF Casting Solutions GmbH in Leipzig manufactures structural cast iron parts for agricultural and forestry machinery and construction machinery as well as for renewable energy systems. "We support our customers in the development and production of highly complex iron casting solutions up to a box format of 2,500 x 1,600 x 500 mm," explains Production Manager Andriy Malashkin.

Deburring is key

Prior to further processing, excess material in the form of trimmings, burrs and risers must be removed. In existing automated fettling stations, an industrial robot carries out the necessary processing steps fully automatically. For some parts, however, the frequent tool changes and nest-related fluctuations in dimensional accuracy affect the cycle time. For this reason, certain parts were previously cleaned manually or outsourced to external service providers. "It is becoming increasingly difficult to find staff for this physically demanding, noisy, dirty and monotonous work," reports Andriy Malashkin. "Outsourcing cannot be a long-term solution either, as transport is associated with delays, costs and lack of predictability."

Reversed processing logic

FILL created a solution for the automated deburring and removal of feeders from parts weighing up to 250 kg. Based on the target contours from their CAD data, this can process numerous different parts with short cycle times, thus closing an automation gap. In the new GRIND PERFORMER fettling and grinding cell developed according to GF Casting Solutions' specifications, an industrial robot is the central element.

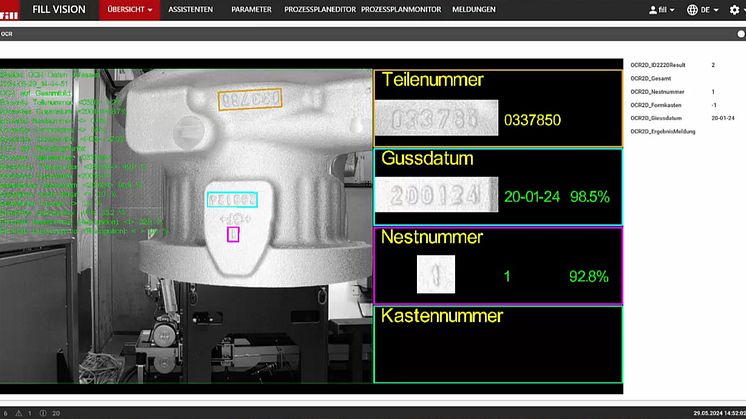

Using camera data on position and orientation, it removes the inserted workpiece and moves it to the various fixed-position tools. This eliminates the delays caused by the otherwise necessary tool changes. Recognising the mould cavity identifier attached to the component in plain text, the cell uses cavity-specific variants of the machining programme. The GRIND PERFORMER can be operated without programming skills using the FILL CYBERNETICS STUDIO software environment.

Solid Results

As well as improving the working conditions for the personnel by eliminating manual fettling, the automated fettling of the new iron castings in the GRIND PERFORMER means practically no reworking. It is an important step towards automating the process chain, contributing substantially to safeguarding the production site.

About Fill

FILL is a leading international machine engineering company based in Gurten, Upper Austria. With sophisticated high-tech systems and custom manufacturing solutions for metal, plastics and wood, Fill makes its customers the best in their fields. The automotive, aviation, sports and building industries all benefit from Fill's expertise.

Since it was founded in 1966, the company has distinguished itself through enormous innovative strength, strong values and the best jobs. "If you are seeking the best solution, shape your future with Fill,” is the guiding principle of the company’s more than 1,000 employees. “We are one!" is their vision and stands for togetherness with the team and with customers, suppliers and partners. The company is 100 percent family-owned and is managed by Andreas Fill (CEO), Martin Reiter (CFO), Alois Wiesinger (CTO) and Günter Redhammer (COO). In 2024, Fill recorded an operating output of 202.5 million euros.

More information can be found at: www.fill.co.at

Media Contact:

Fill Gesellschaft m.b.H.

Martina Moserbauer

Fillstraße 1, A-4942 Gurten

Tel.: +43 7757 7010-7404

www.fill.co.at