Blog post -

Complete integration package increases automation and streamlines processes from order to delivery

WallVision designs, manufactures and sells high-quality wallpapers globally. The company’s vision is to become the leading international supplier of premium wallpaper. This demands exacting standards in terms of quality, production efficiency and delivery reliability. To help it achieve these objectives, WallVision has invested in an integration solution that reduces manual processes and delivers clear benefits in a number of areas.

Working closely with Connect Companies, WallVision has decided to switch from using a separate system for orders and production control for digital wallpaper printing, to a solution that is fully integrated with the Jeeves ERP system. The solution, which is based on Blue Integrator and software from Connect Companies, has resulted in increased automation and significant streamlining of processes from order to delivery.

“Our previous system was high-maintenance and inaccessible, and there was a great deal of duplication. Today, we have a solution that coordinates the order process from online order placement right through to the ERP system. This provides us with significant time savings and fewer sources of error. At the same time we have established more conducive conditions for working with digital printing,” says Terese Larsson, Director IT at WallVision.

Growing interest in digital printing amongst wallpaper manufacturers

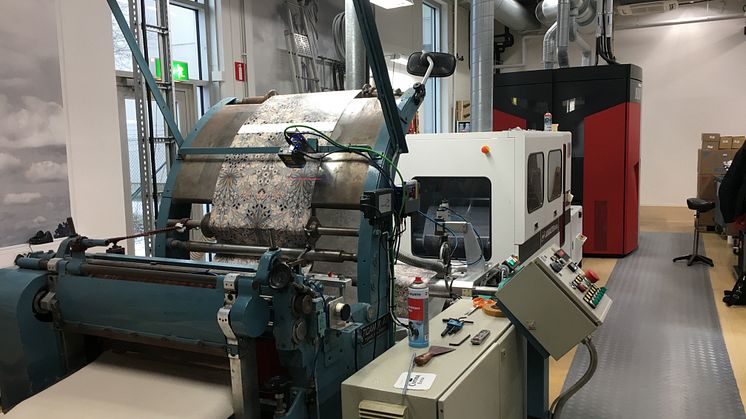

Working with digital wallpaper printing means converting an image file into a design on lengths of wallpaper. It is quite a demanding process that can now be managed and performed directly in the ERP system. Using Connect Companies’ CAIE and CCWA software, the ERP system and production equipment can now communicate in real time. When a wallpaper is ready, a signal is sent from the printing equipment to the ERP system.

As printing equipment continues to develop, more and more wallpapers will be produced using digital print technology.

“The vast majority of our wallpapers are still produced using traditional methods, but there is clearly a growing demand for digital printing. In addition to an integration solution and digital print technology which streamlines and simplifies our work, we are now able to offer our customers quick and reliable information about where in the process their orders are,” continues Terese.

The new integration solution has also enabled work to be outsourced to the company’s subsidiaries. For example, the UK operation is now able to process and review its own orders in a completely different way.

“We are in an excellent position to expand digital production. The introduction of an additional printing line has been noticeably easier than it would have been with the previous solution, which was built for a production line.”

Blue Integrator – a success story

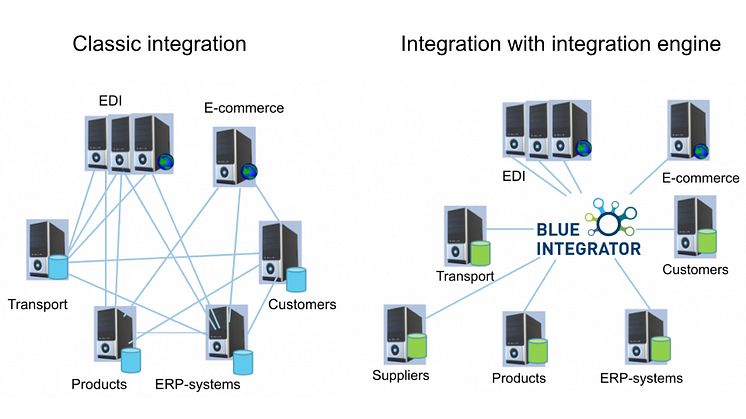

An important component of the new solution is Connect Companies’ integration engine, Blue Integrator.

“The best thing about the integration engine is that we don’t even know it’s there. It’s a real plus. It does its job brilliantly. Blue Integrator has also proved valuable in another project where we are now able to export stock balances to a third party,” continues Terese.

“The commissioning process was extremely smooth. We were fully prepared to roll back to the old solution if necessary, but there was never any question of that happening, as everything worked as it should right from the off. We have experienced very few issues throughout and the standard of delivery has been exceptional. Connect Companies has contributed important knowledge and demonstrated a structured approach during this process. That is as much a key to the success as the technology itself.”

Centralised production in Borås

WallVision has centralised all production at its state-of-the-art factory on the Viared business park in Borås. The factory employs both traditional production techniques and new streamlined production methods.

“With this new integration solution, we have been able to transform our procedures for delivery and picking, which can now be quality-assured in a completely different way. We are now better able to ensure that the right number of rolls of wallpaper are in the right place at the right time. We also appreciate that this new solution has cut the time for order management and item administration by 25 per cent,” concludes Terese Larsson.

The new integration solution means, amongst other things:

- Reduced administration during order management.

- More opportunities to reorganise production quickly.

- Greater access to quick and reliable information.

- Reduced manual processing – fewer sources of error.

- Shorter lead times from order to delivery.

The solution is based on the following components/software:

- Blue Integrator – integration engine

- CAIE – integration platform

- CCWA – client software that runs on CAIE