Hygiene begins long before cleaning starts

How weighing and inspection technologies actively enable hygiene.

How weighing and inspection technologies actively enable hygiene.

How can the highest precision be realised in a small space? Together with its local partner EAST, Minebea Intec has developed a checkweigher for Unilever Egypt that is precisely tailored to the requirements of detergent production.

Minebea Intec, a leading global manufacturer of weighing and inspection technologies, received the award for the user interface Blue HMI in Berlin in November.

When tradition and precision meet, solutions with a special character are created. Together with Kilomatic Wiegetechnische GmbH, Minebea Intec has modernised a track scale from the 1960s with the latest load cells and associated electronics. The result: maximum accuracy with complete preservation of the historic steel body.

Accurate fill level detection in silos, tanks and process containers is essential for stable, safe and efficient production. This article compares radar, ultrasound and capacitive sensors with the gravimetric method – revealing why weighing technology excels where it truly counts.

Food safety starts with precise weighing – and goes far beyond. Weighing systems are crucial for product quality, legal compliance, and preventing recalls. The Minebea Intec MiNexx® portfolio meets these demands with bench and floor scales, plus powerful weight indicators for silo, hopper, and truck applications.

Minebea Intec, a leading global manufacturer of industrial weighing and inspection technologies, is setting the course for further international growth: With the return of Frank Wieland as Chief Sales Officer (CSO), the company is sending a clear signal to strengthen its global sales activities.

One interface for all applications: The advanced Blue HMI from Minebea Intec has won the prestigious Red Dot Award for Interface & User Experience Design, recognising outstanding product design that unites functionality, innovation and aesthetics.

Minebea Intec, a leading global manufacturer of industrial weighing and inspection technologies headquartered in Hamburg, Germany, and Baykon, Türkiye’s market leader for industrial weighing, have formed a strategic partnership. The alliance combines Minebea Intec’s inspection expertise with Baykon’s strong market access to further strengthen customer proximity in Türkiye.

Minebea Intec, a global leader in industrial weighing and inspection technologies, is expanding its production capacity and optimising lead times to better meet the growing demand for its high-precision and durable load cells. The company has invested a seven-figure sum in a new 2-tonne dead load testing machine and a new turning centre at its Hamburg site.

Minebea Intec, a leading global manufacturer of industrial weighing and inspection technologies will present three new, high-performance weight indicators which form part of the MiNexx® family at PPMA 2025 in Birmingham from 23-25th September.

Minebea Intec expands the MiNexx® family with three new weight indicators and the MiNexx® 3000 floor scale – combining precision, connectivity and adaptability for all industrial applications.

Minebea Intec will showcase advanced weighing and inspection technologies at Anuga FoodTec India 2025, focusing on packaging quality. Key offerings include the Identus X-ray system and Vistus RS metal detector, enhancing food safety, compliance, and efficiency in packaging processes.

Nearly 400 dairy product recalls in Q1 2025 put the industry back in the spotlight. This article explores key risk points along the production process and highlights technologies that boost safety and efficiency.

When the existing procedures at a US Cosmetics Manufacturers were no longer meeting expectations, it was time to introduce a new solution combining weighing equipment and software to deliver better results.

On the Scales, ready, quality! The Flexus® checkweigher and the SPC@Enterprise software solution from Minebea Intec under support the production of Vital Products, a leading contract manufacturer of nutritional supplements. Thanks to precise weight control and comprehensive process monitoring , the quality of the filled tablets and capsules in plastic bottles is guaranteed.

Whether grinding, mixing or filling - where tonnes of grain are moved every day, nothing can be left to chance. Minebea Intec supplies highly accurate weighing and inspection solutions that enable milling companies to organise their processes safely, efficiently and compliantly - even in hazardous areas.

The new supply centre of the agricultural chemical and pharmaceutical company Bayer in Hangzhou integrates weighing technology of Minebea Intec for precise mixing and homogenisation in Zone 2 hazardous areas. Features like smart calibration save time and labor, while seamless system integration ensures scalability.

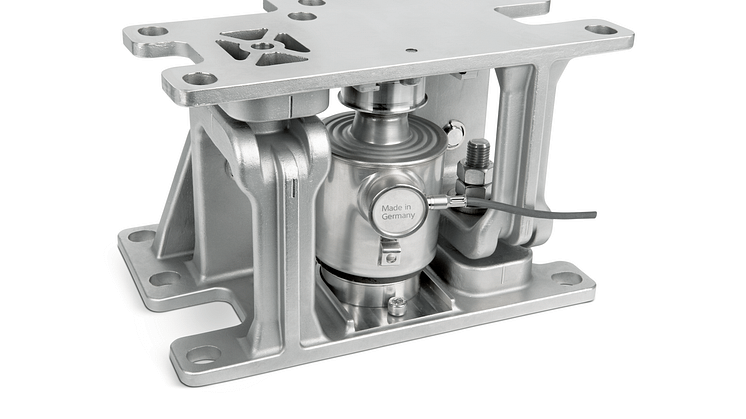

The PR 6003 mounting kit from Minebea Intec sets new standards in industrial silo weighing: fast to install, highly accurate, and exceptionally safe – all in one compact system. Specially designed for demanding applications, it's available to order now.

Severe flooding put the weighing system of Dubai’s largest waste incineration plant to the test. After 48 hours under water, it resumed operation without damage – a testament to the resilience of Minebea Intec technology.