Press release -

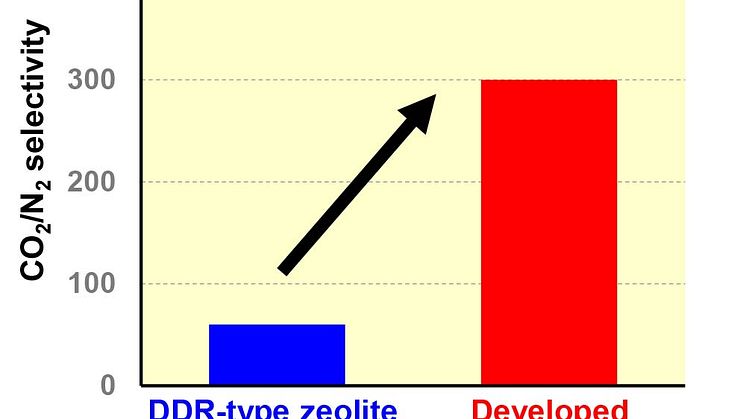

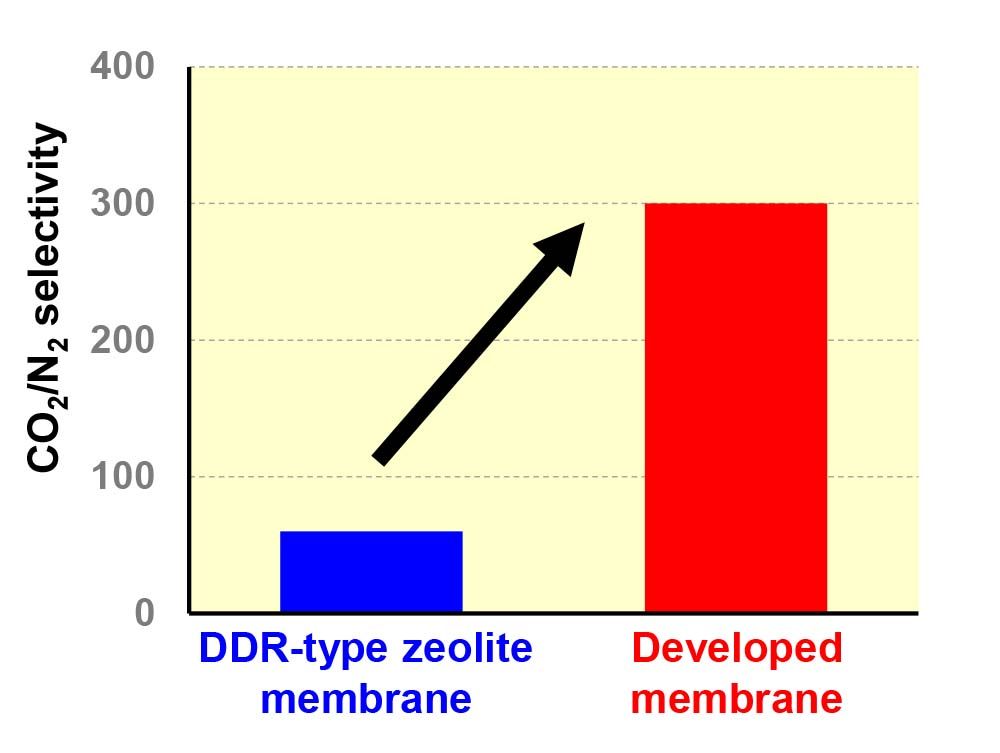

CO2 Separation Membrane Developed for Industrial Exhaust Gas ~ Confirmed Approximately Five Times the Separation Factor of DDR-Type Zeolite Membrane

NGK INSULATORS, LTD. (“NGK”) has developed a carbon dioxide (CO2) separation membrane for industrial exhaust gas. In testing with simulated industrial exhaust gas, the membrane achieved CO2 separation factor approximately five times that of conventionally developed DDR-type zeolite membrane used for CO2 separation. The Company aims to continue with development for further increases in separation performance, aiming for commercialization in 2030 after demonstration testing.

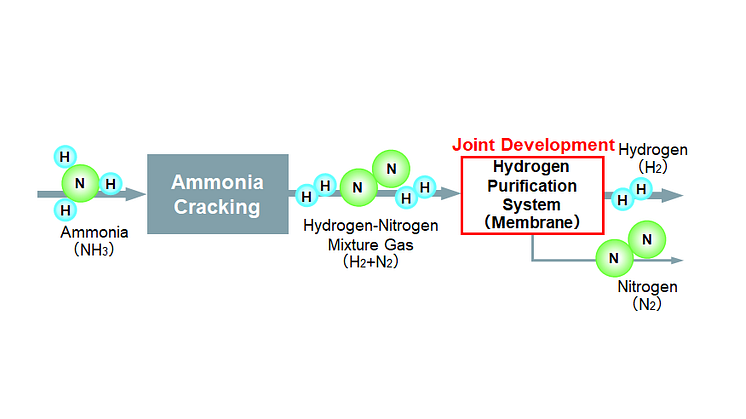

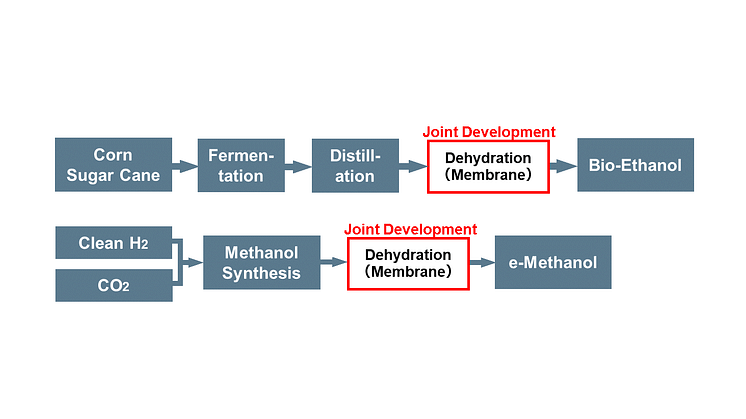

The Company has been successful in developing a DDR-type zeolite membrane, which is one of the world’s largest ceramic CO2 separation membranes. Demonstration testing of these membranes is currently in progress with a view to using them for separating CO2 from associated gas and natural gas. Amid a global shift towards carbon neutrality, there is a growing social need for CO2 separation and recovery technology for industrial exhaust gas emitted from plants and so forth. NGK has therefore used its large membrane manufacturing technologies and technologies for forming uniformly membranes to develop a new CO2 separation membrane for industrial exhaust gas.

The conventionally developed DDR-type zeolite membrane can be used for CO2separation using differences in molecule size. It is easily able to separate CO2in associated gas and natural gas, since methane, their major component, has a larger molecule size than CO2. On the other hand, in industrial exhaust gas, the major components are nitrogen and oxygen, which have molecule sizes similar to CO2. Therefore, it is difficult to precisely separate CO2 from industrial exhaust gas using a DDR-type zeolite membrane. The newly developed CO2 separation membrane for industrial exhaust gas makes use a difference in adsorption characteristics (affinity) for molecules to separate CO2 from nitrogen and oxygen, which increases CO2 separation factor. In testing uses simulated industrial exhaust gas, the new membrane was confirmed to have approximately five times the CO2separation factor of a conventionally developed DDR-type zeolite membrane. Using the characteristics of ceramics, which can be used under harsh conditions, the Company is working to increase the separation factor even further for high temperature industrial exhaust gases, aiming for commercialization in 2030 after demonstration testing.

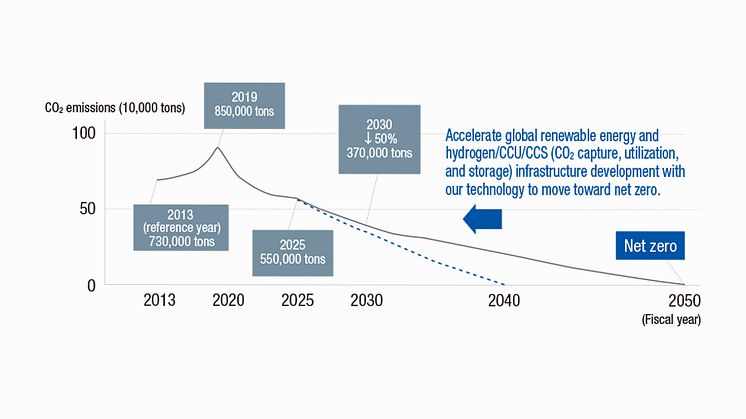

In April 2021, the NGK Group formulated the NGK Group Environmental Vision. The vision calls for 50% reduction in CO2 emissions compared with fiscal 2013 by fiscal 2030 and aims to achieve net zero emissions by fiscal 2050. Through the development and provision of various membrane technologies going forward, NGK will work to reduce CO2 emissions through the spread of technologies for the separation, recovery, and effective use of CO2, and contribute to the realization of carbon neutrality.

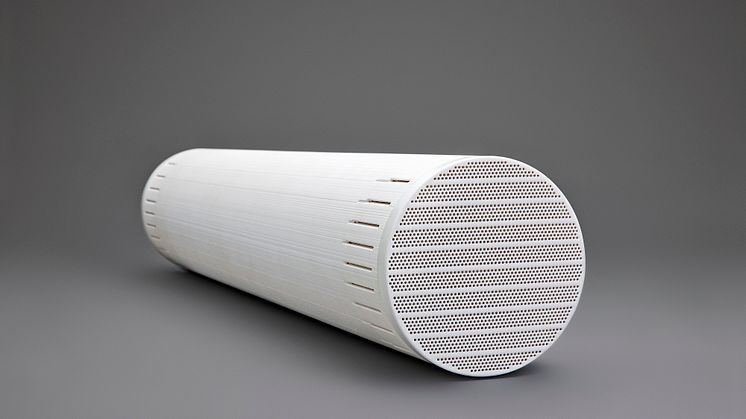

Subnano-ceramic membrane

Subnano-ceramic membrane separation system

Comparison of separation factor of CO2 and nitrogen (N2)

Related links

Topics

Categories

About NGK Insulators

NGK INSULATORS (NGK) is a leading company in the field of ceramics.

Since its foundation in 1919, NGK has used its unique ceramic technology to provide numerous ground-breaking products that solve social issues. Today, NGK is active in more than 20 countries worldwide, with business foci including mobility, energy, IoT and industry. As one of the largest manufacturers of ceramic substrates for automotive catalytic converters, NGK has built on this to also develop new products and businesses with ceramics that actively reducing the strain on our global environment.

Furthermore, NGK’s products include the energy storage system “NAS” batteries, in addition to the compact, thin, and high-energy-density lithium-ion rechargeable battery “EnerCera” line, vital tools for sustainable energy infrastructure.

NGK focuses on the two business fields “carbon neutrality” and” digital society” and is aiming to realize 80% of total company sales in these two fields whilst also achieving net-zero CO2 emissions by 2050. Through providing innovative, high-quality products, NGK is committed to contributing to our society. In order to create a future where people can coexist with nature, NGK will continue to develop and provide products that support social infrastructure while preserving the environment.