Press release -

NGK and Mitsubishi Heavy Industries to Jointly Develop Membrane Dehydration Systems for Bioethanol and e-Methanol

♦ NGK and MHI aim to achieve the real-world realization of systems using membrane separation system in the dehydration processes for Bioethanol, a promising alternative to gasoline and raw material for Sustainable Aviation Fuel (SAF), and e-Methanol, a next-generation clean marine fuel.

♦ By utilizing membrane dehydration systems, the companies will work to realize low-cost and to optimize the efficiency of their manufacturing processes of next-generation clean fuels contributing to the future establishment of a stable supply system.

Nagoya, Japan, and Tokyo, May 22, 2024 – NGK INSULATORS, LTD. (NGK) and Mitsubishi Heavy Industries, Ltd. (MHI) will jointly develop two membrane dehydration systems to realize of low cost and to optimize efficiency of manufacturing processes for Bioethanol and e-Methanol to meet expected demand growth for clean fuels and raw materials.

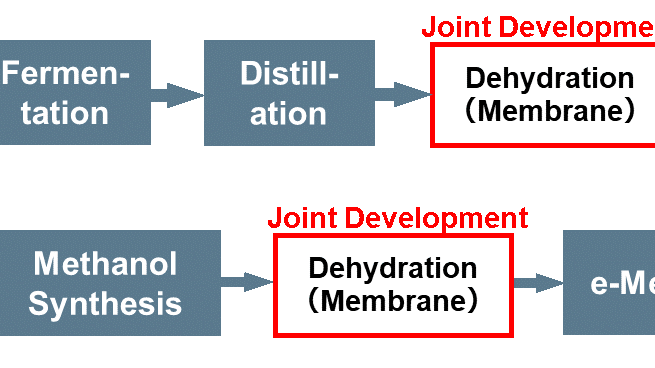

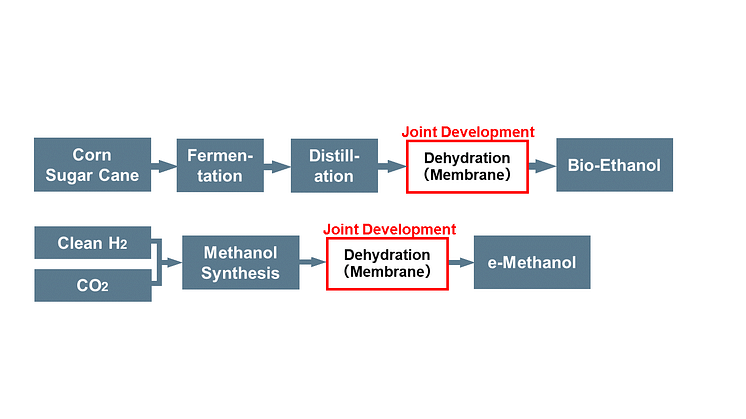

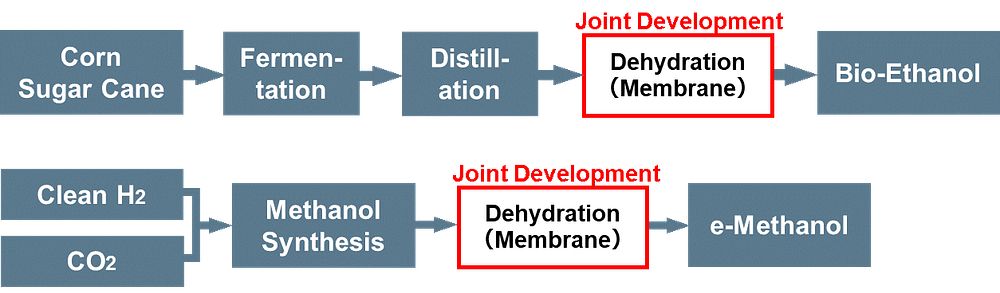

In this project, MHI and NGK will begin developing two types of membrane dehydration systems, one for Bioethanol and e-Methanol, respectively. The membrane separation system* developed for Bioethanol will replace the conventional dehydration process, which consumes the most energy in the Bioethanol manufacturing process. This replacement is expected to achieve a significant reduction in energy required to produce Bioethanol.

The second system will replace the dehydration process in the production of e-Methanol, which utilizes hydrogen and CO2 as raw materials. By using a membrane separation system instead, the companies expect to significantly reduce energy consumption used in the manufacture of e-Methanol, which is capturing attention as a next-generation clean fuel.

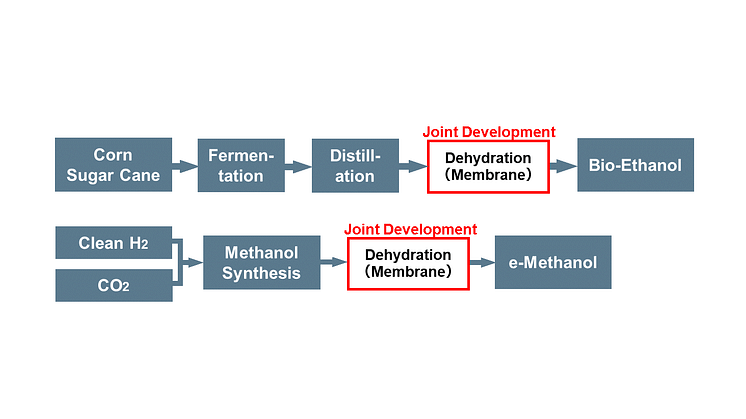

To this project, MHI will contribute its significant global expertise delivering methanol plants and other chemical plants, in addition to its technologies for handling methanol and various other chemicals. NGK will contribute its deep knowledge of sub-nano ceramic membrane technology and unique film deposition technology developed in the fields of chemical processes and water purification. Notably, NGK has developed the world's largest ceramic membranes, which are known for their exceptional separation accuracy and durability. In the context of forecasted demand growth for both Bioethanol and e-Methanol as clean, raw materials and fuels, MHI and NGK will jointly drive forward the development of these systems achieve real-word deployment and establishment of a stable supply system.

Bioethanol is a clean fuel derived from plants, primarily corn and sugarcane, and is widely used as automotive fuel in the United States and Brazil. It is also expected to contribute to the growth of Sustainable Aviation Fuel (SAF) as one of its main raw materials. e-Methanol is gaining attention as a next-generation clean fuel, primarily for marine fuel, and is expected to grow as a market globally.

MHI Group is pursuing a growth strategy in the area of Energy Transition, aiming for decarbonization on the energy supply side to support the Company's goal of achieving Carbon Neutrality by 2040. Through the development and commercialization of a high-efficiency manufacturing processes for hydrogen-free Bioethanol and e-Methanol, the Company will strive for early establishment and execution of decarbonization technologies, as a way of contributing to the realization of a sustainable, Carbon-Neutral world.

NGK Group has formulated a "Carbon Neutrality Strategic Roadmap" consisting of four strategies to contribute to the realization of a carbon-neutral society and promoting the development and provision of hydrogen and Carbon dioxide Capture, Utilization and Storage (CCUS) related technologies, and products. NGK will contribute to society through our business by realizing what has previously been difficult with ceramic technology at the core, and by working to the point where the key devices are implemented in society.

*Membrane separation refers to a method of separating substances using membranes based on the difference in molecular size.

Related links

Topics

Categories

About NGK Insulators

NGK Insulators (NGK) is a leading company in the field of ceramics. Since its foundation in 1919, NGK has used its unique ceramic technology to provide numerous ground-breaking products that solve social issues. Today, NGK is active in more than 20 countries worldwide, with business foci including mobility, energy, IT and industry.

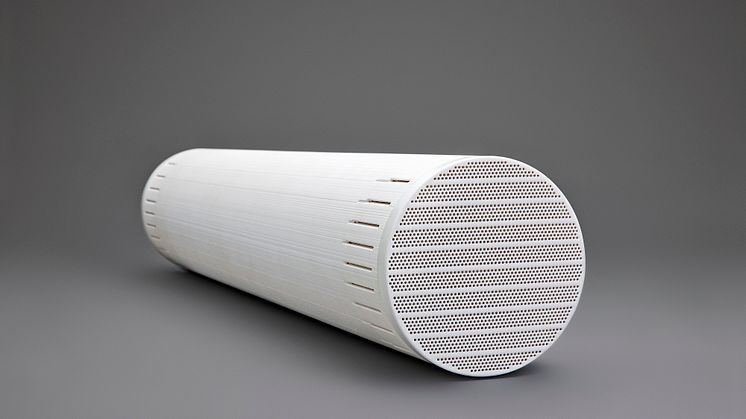

As one of the largest manufacturers of ceramic substrates for automotive catalytic converters, NGK is actively reducing the strain on our global environment. Furthermore, NGK’s products include the energy storage system “NAS” battery, in addition to the compact, thin and high-energy-density lithium-ion rechargeable “EnerCera” battery line, vital tools for sustainable energy infrastructure.

Through providing innovative, high-quality products, NGK is committed to contributing to our society. In order to create a future where people can coexist with nature, we will continue to develop and provide products that support social infrastructure while preserving the environment.